Patents

Literature

37results about How to "Promotes uniform deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

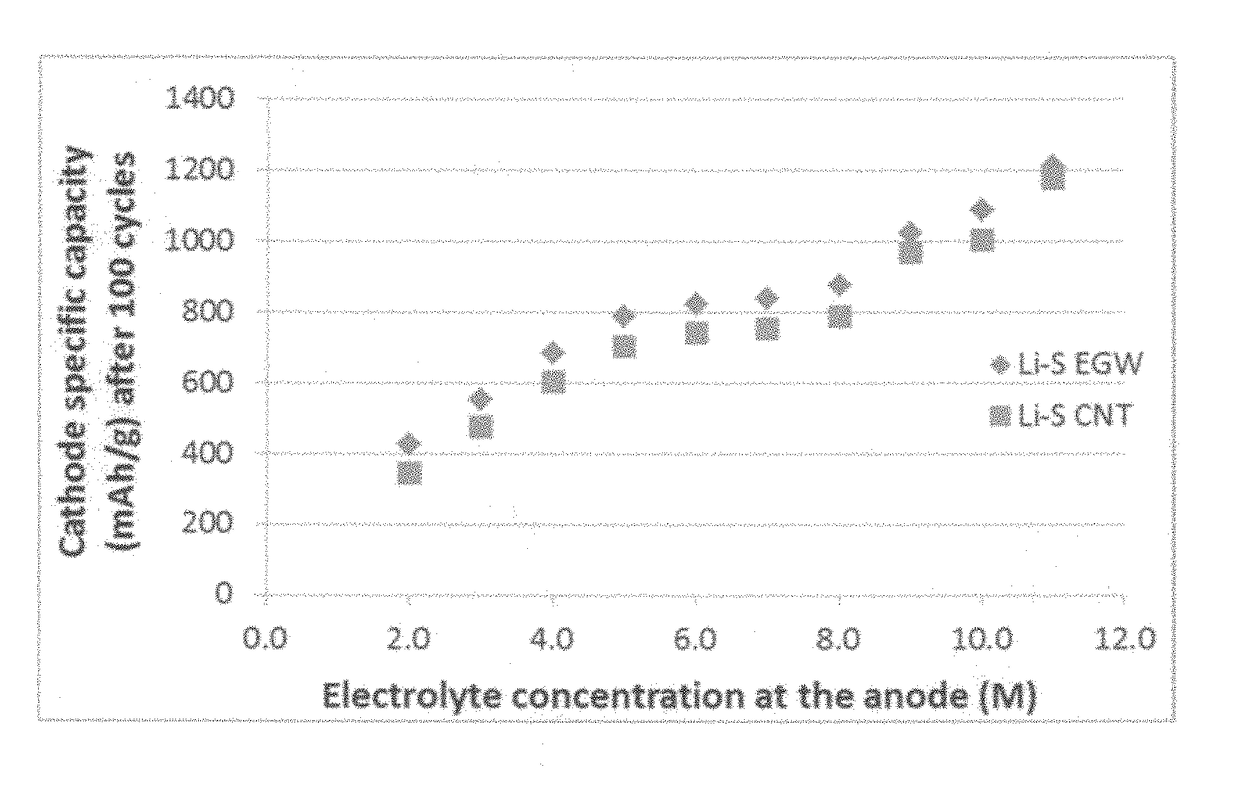

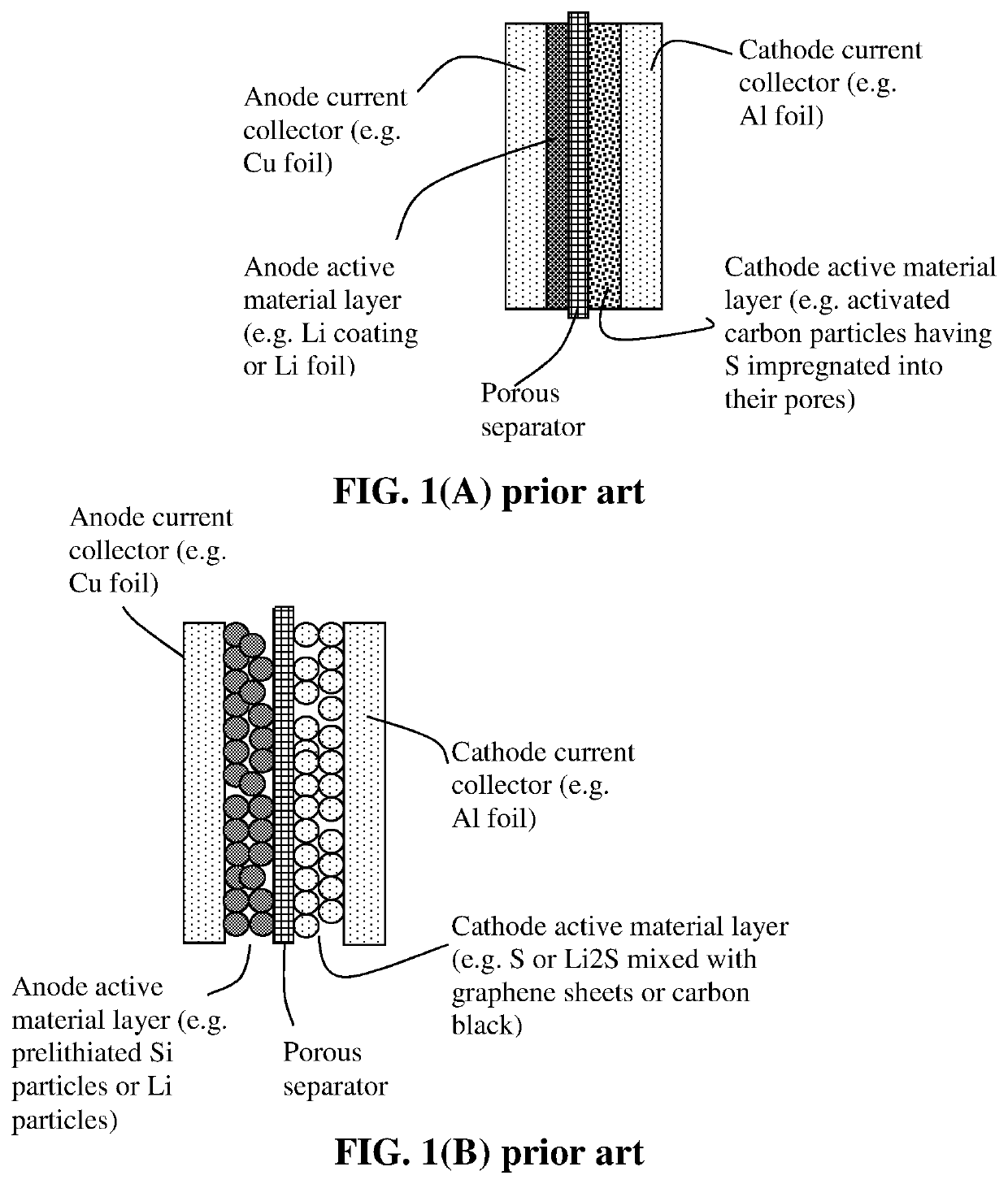

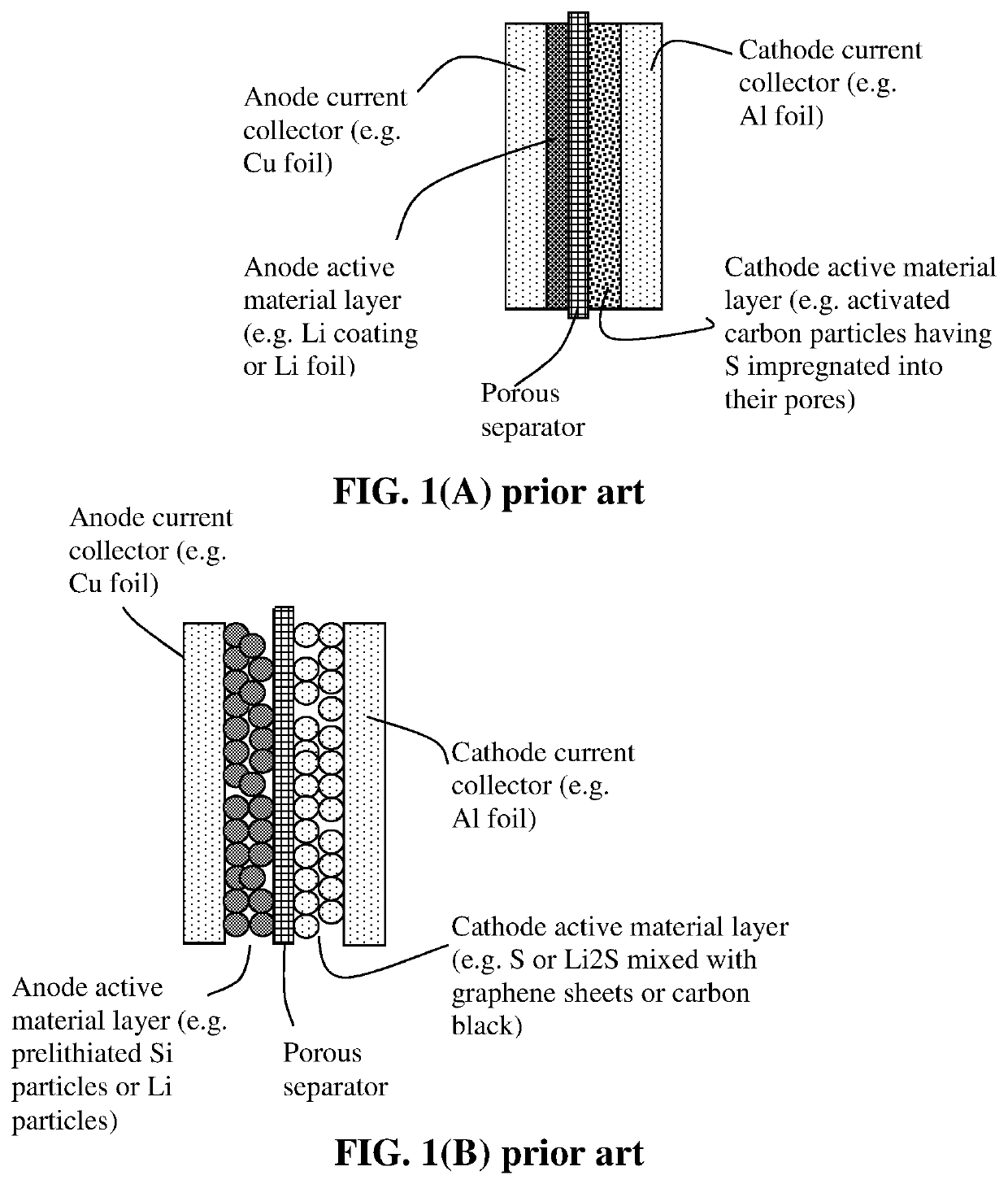

Lithium-sulfur secondary battery containing gradient electrolyte

ActiveUS20140342209A1Reduce electrical conductivityLow ionic conductivityElectrode carriers/collectorsTwo electrolyte cellsLithium sulfurBattery cell

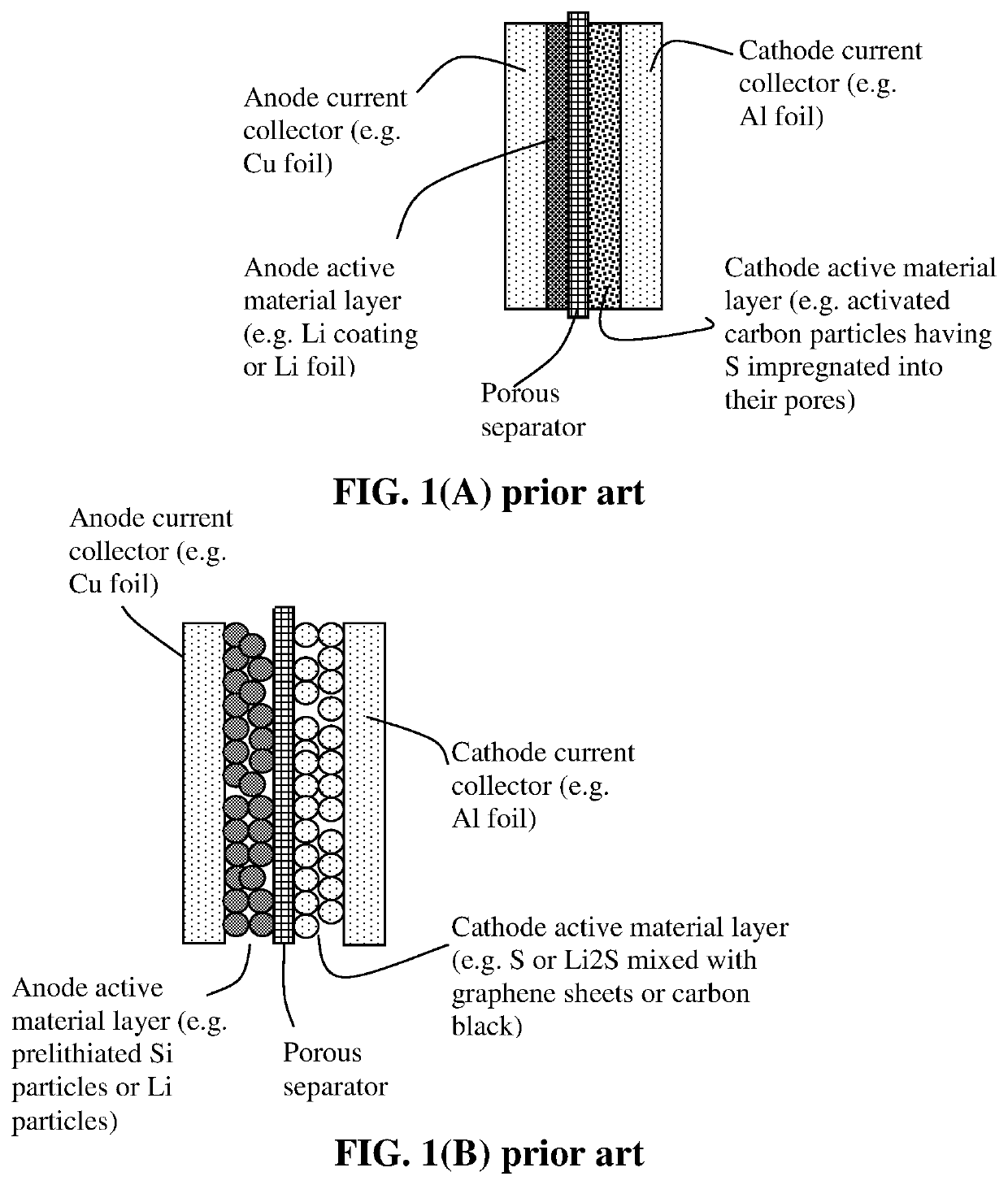

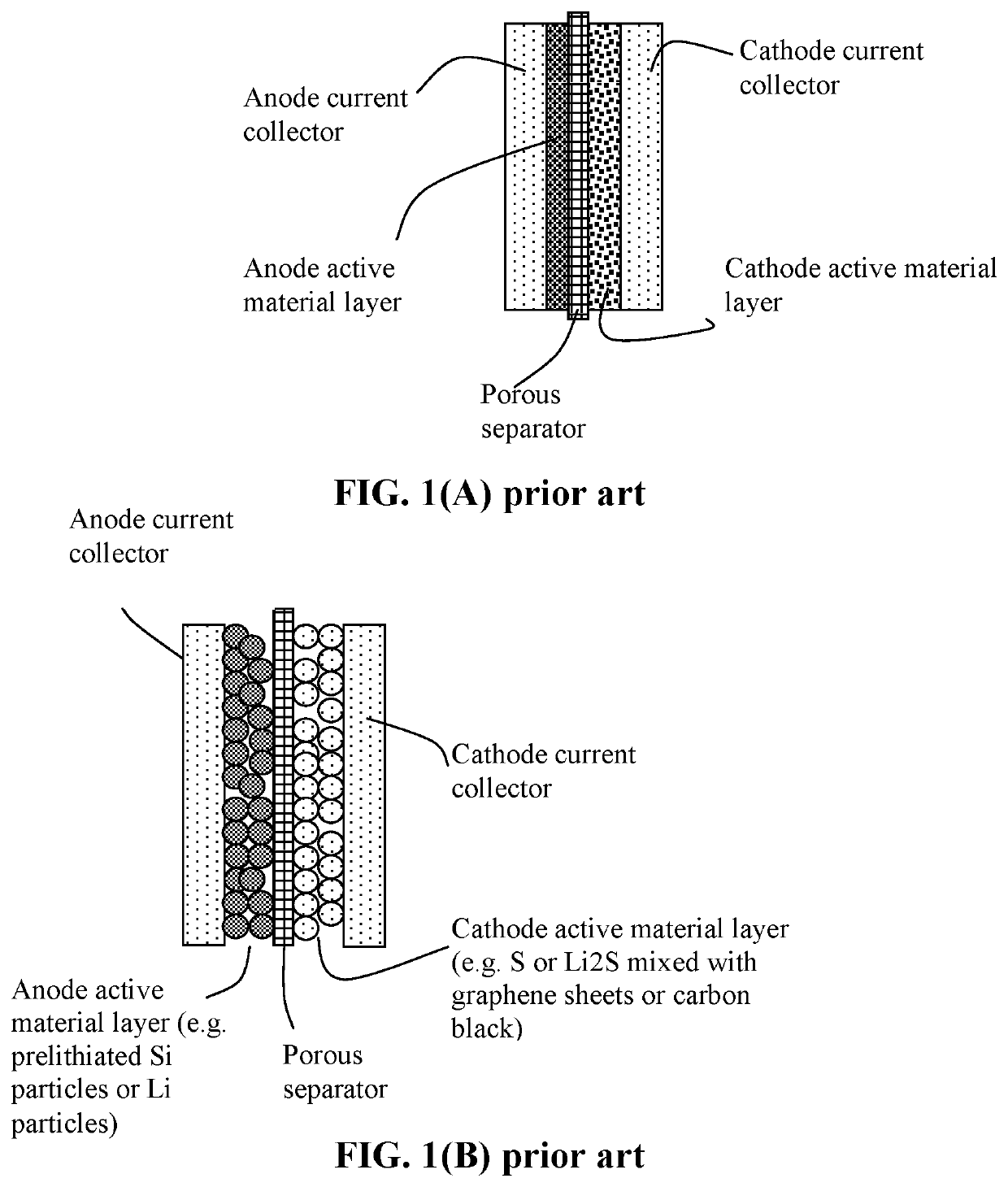

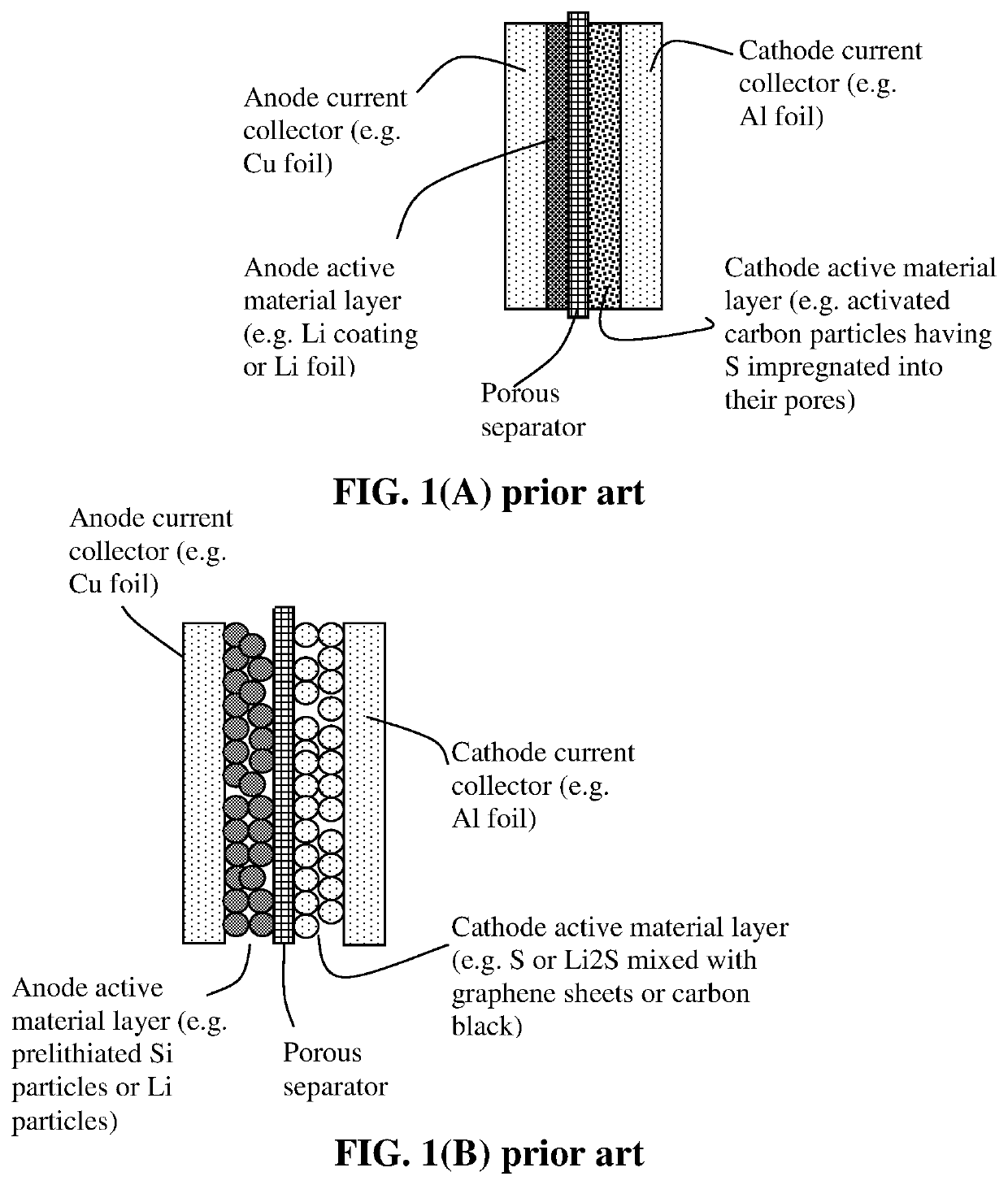

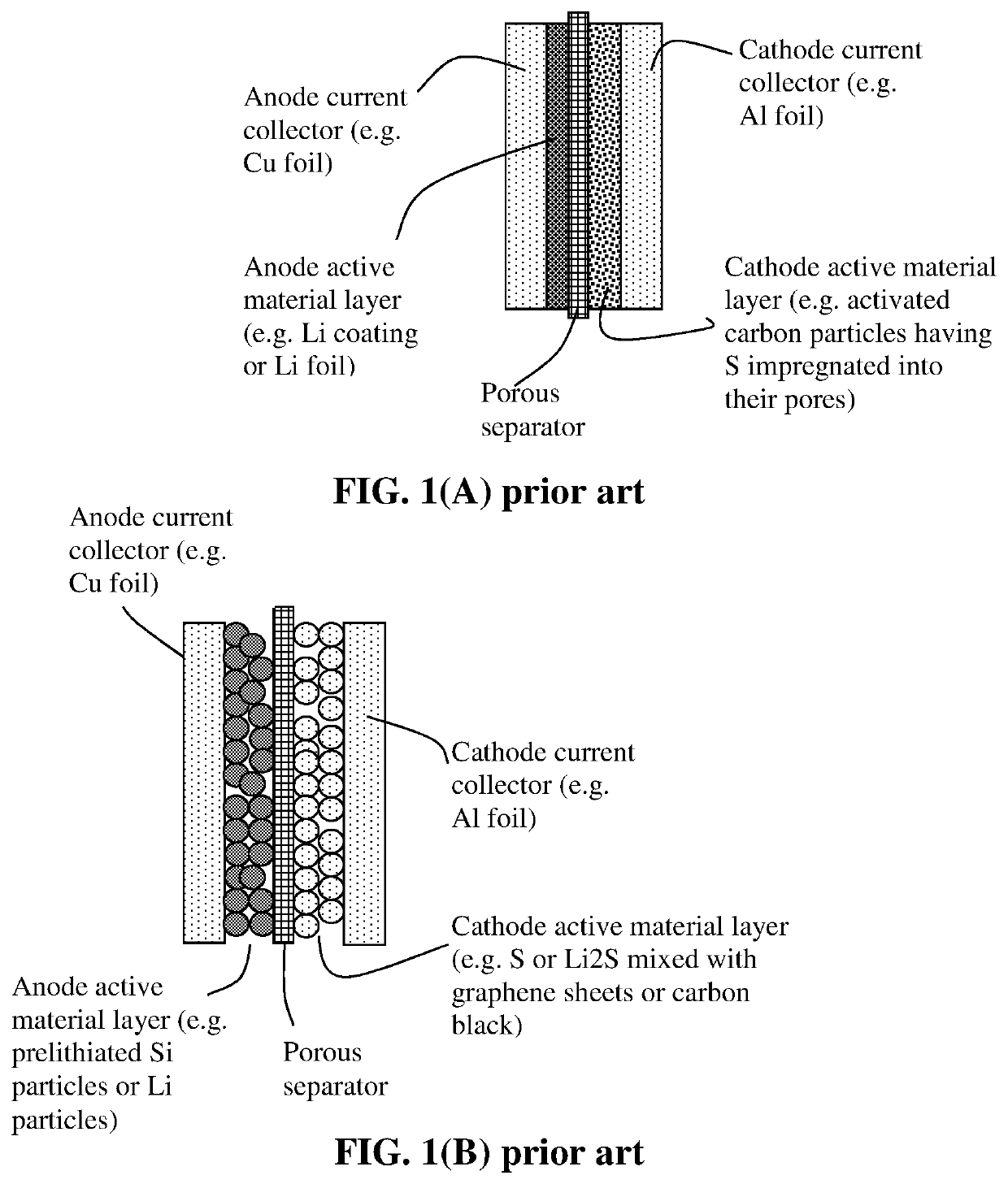

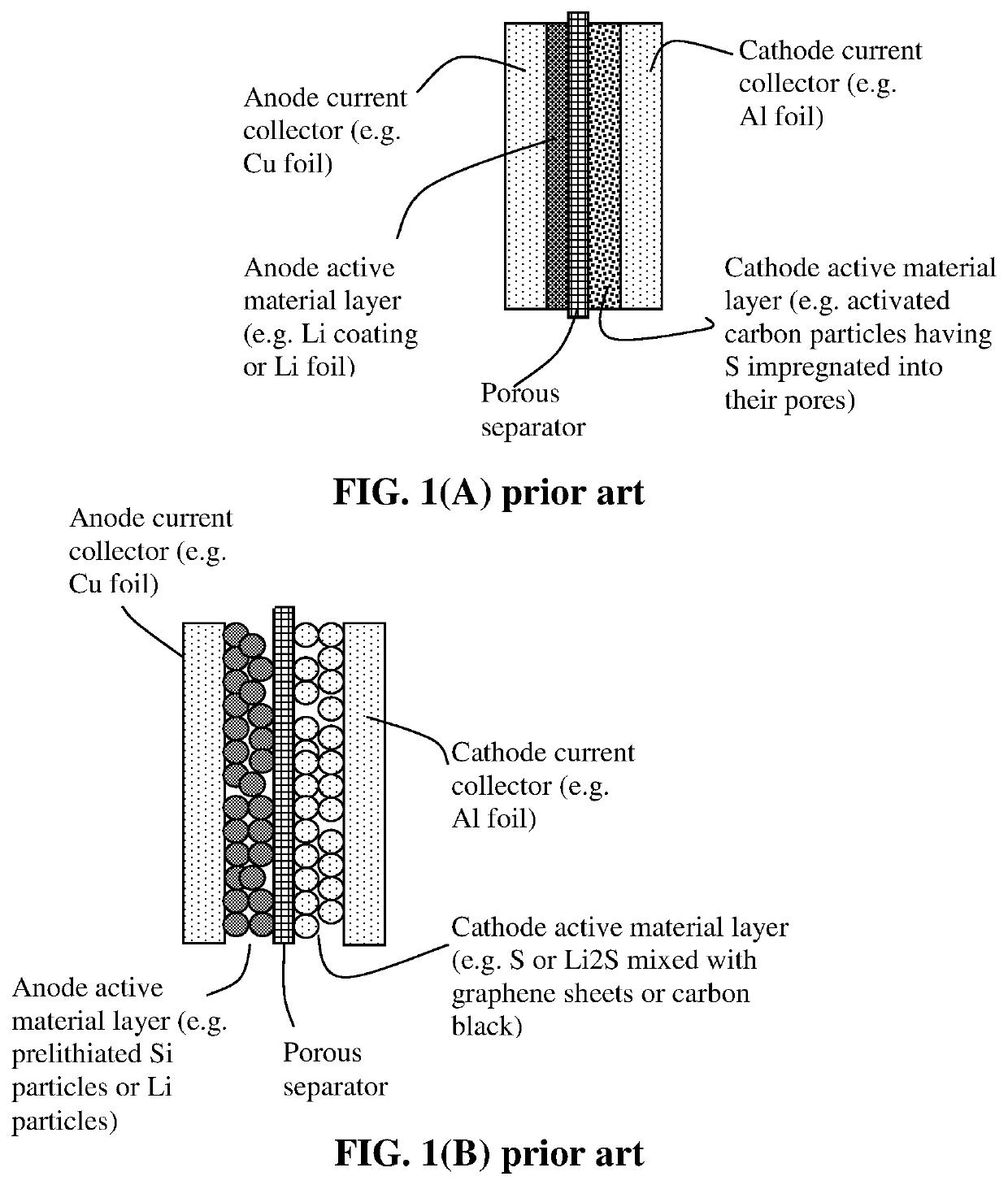

A rechargeable lithium-sulfur cell comprising a cathode, an anode, a separator electronically separating the two electrodes, a first electrolyte in contact with the cathode, and a second electrolyte in contact with the anode, wherein the first electrolyte contains a first concentration, C1, of a first lithium salt dissolved in a first solvent when the first electrolyte is brought in contact with the cathode, and the second electrolyte contains a second concentration, C2, of a second lithium salt dissolved in a second solvent when the second electrolyte is brought in contact with the anode, wherein C1 is less than C2. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

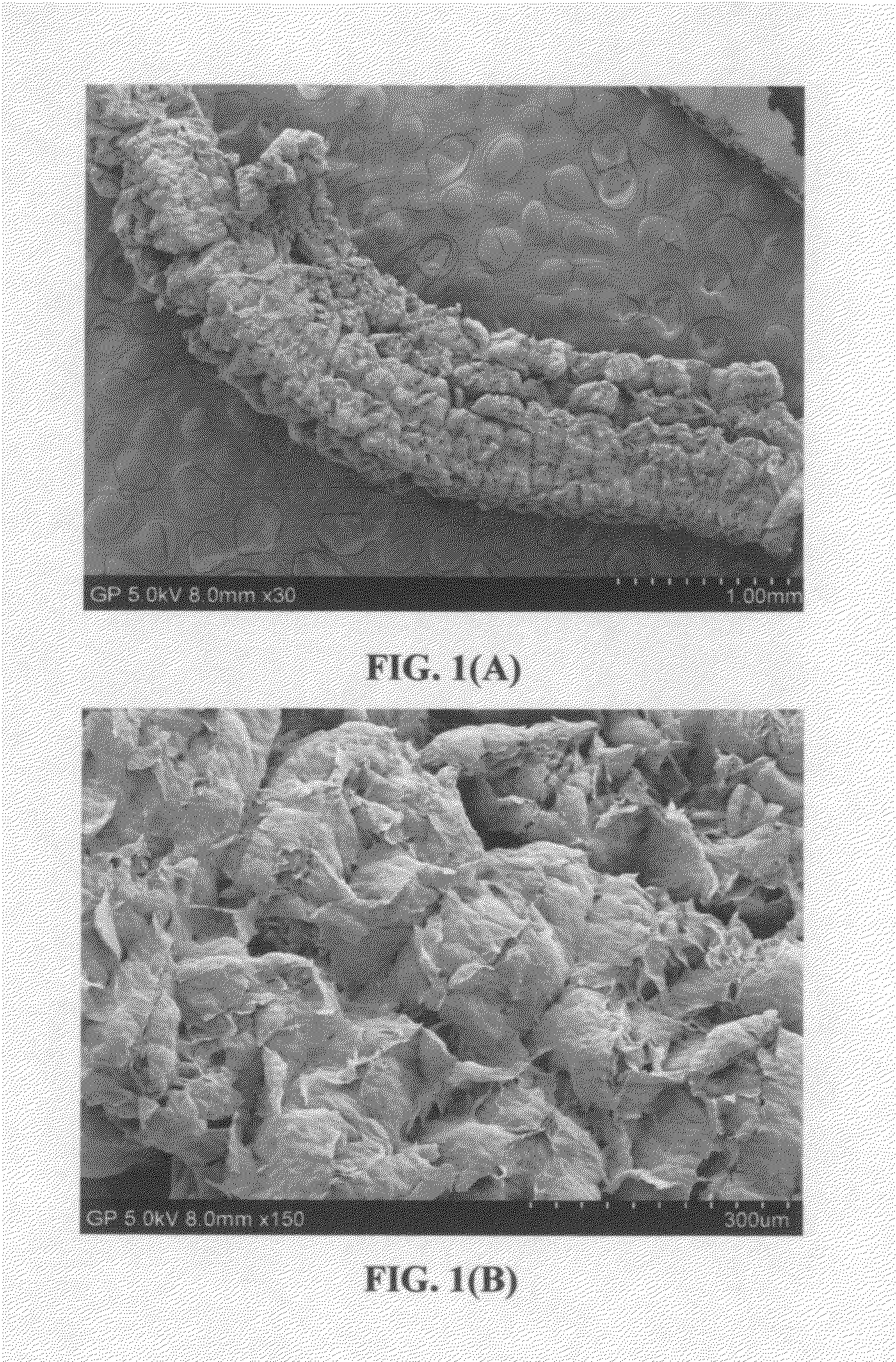

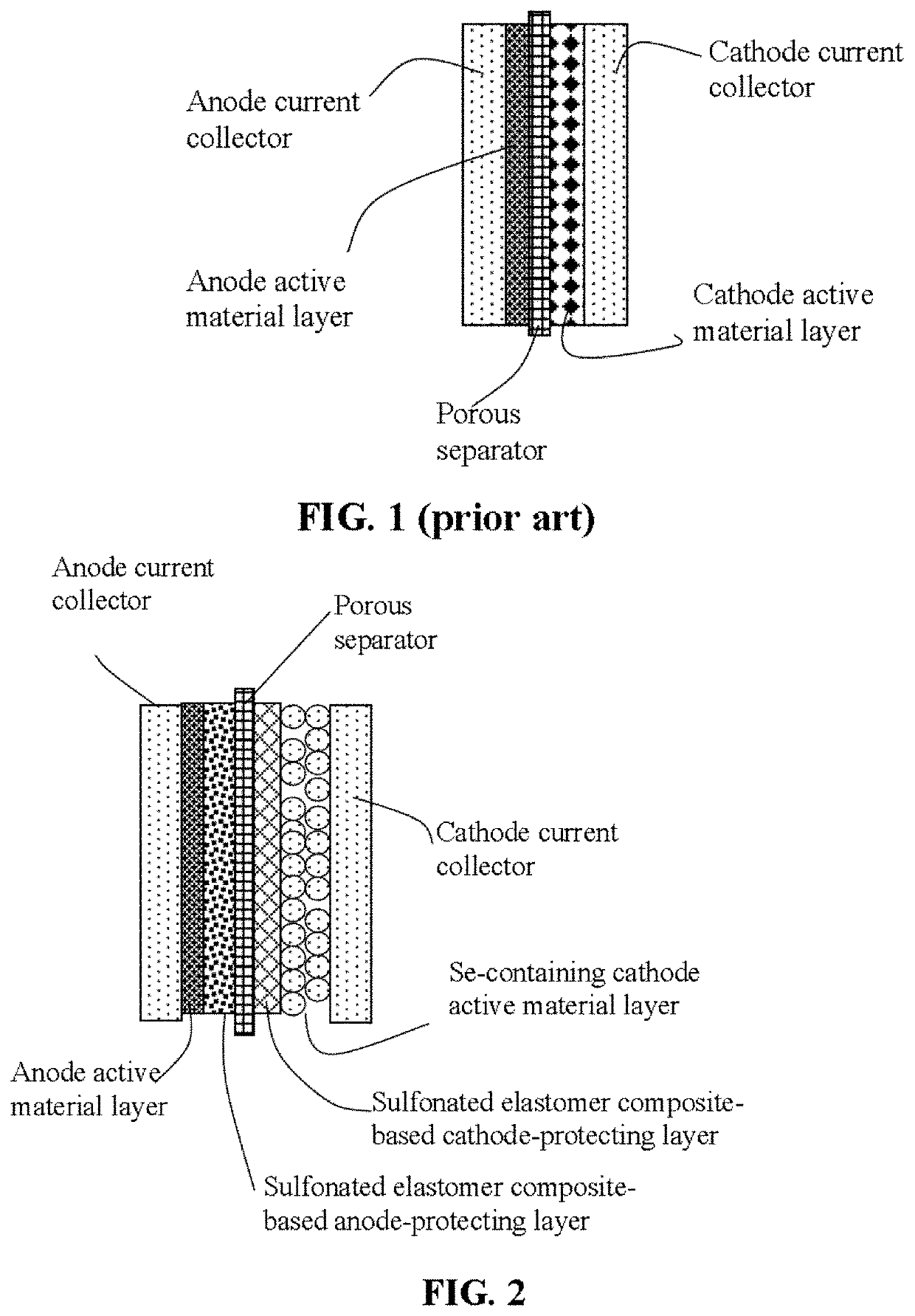

Lithium-selenium battery containing an electrode-protecting layer and method of improving cycle-life

ActiveUS20190393510A1Reduce the impactReduce and eliminate effectCell electrodesFinal product manufactureElastomerAlloy

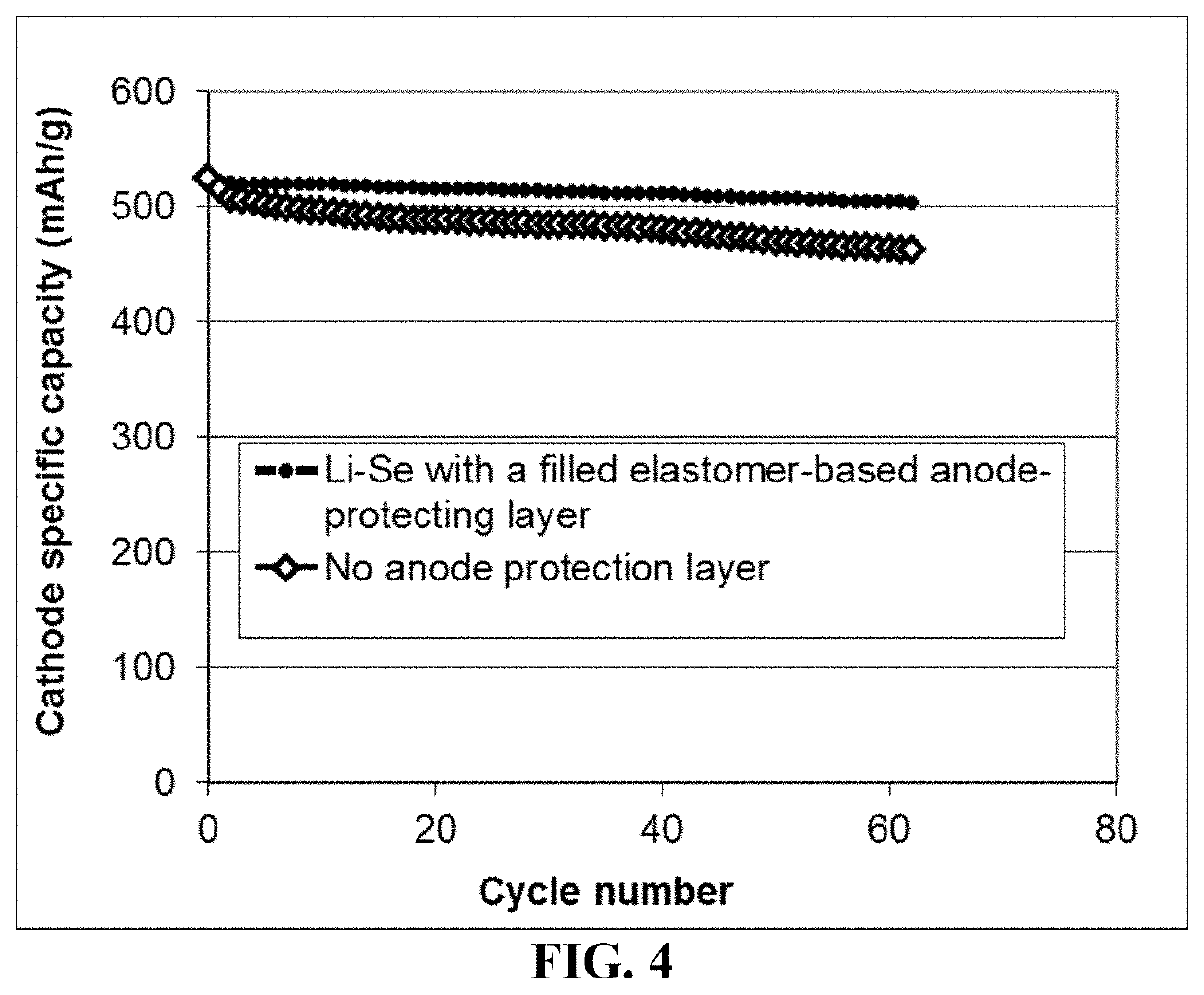

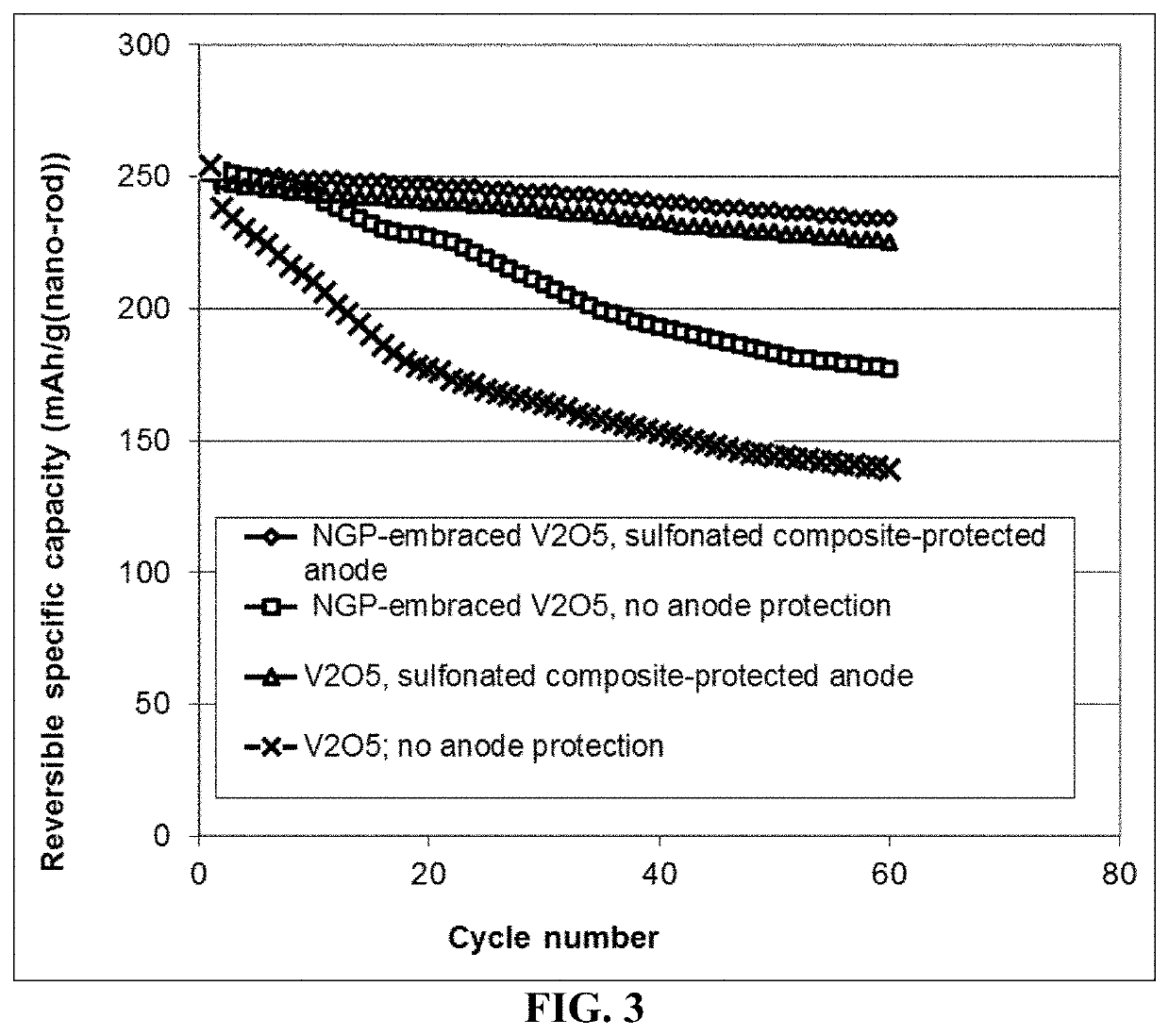

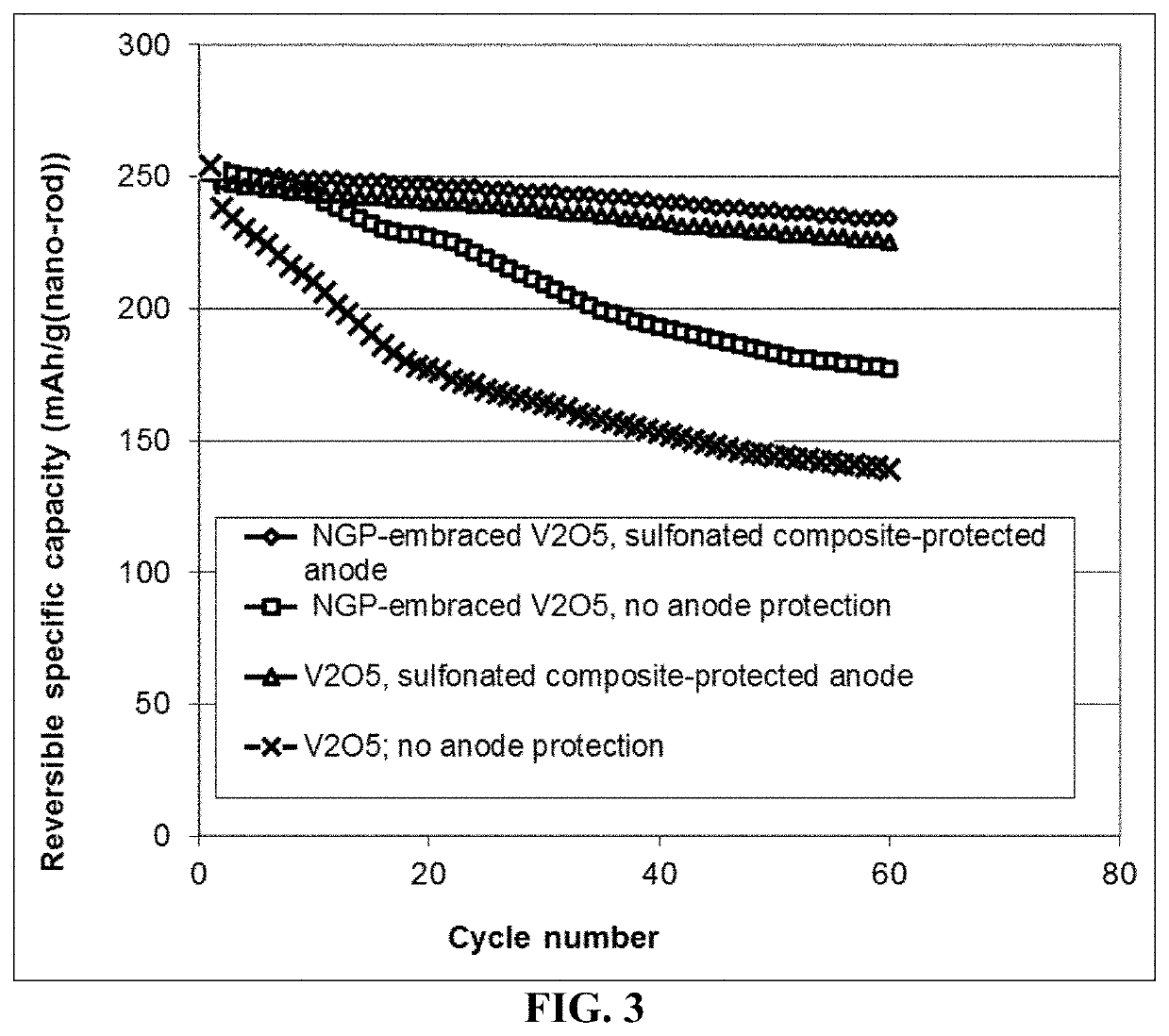

Provided is a lithium-selenium battery, comprising a cathode, an anode, and a porous separator / electrolyte assembly, wherein the anode comprises an anode active layer containing lithium or lithium alloy as an anode active material, and the cathode comprises a cathode active layer comprising a selenium-containing material, wherein an anode-protecting layer is disposed between the anode active layer and the separator / electrolyte and / or a cathode-protecting layer is disposed between the cathode active layer and the separator / electrolyte; the protecting layer comprising from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an electrochemically stable inorganic filler dispersed in a sulfonated elastomeric matrix material and having a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

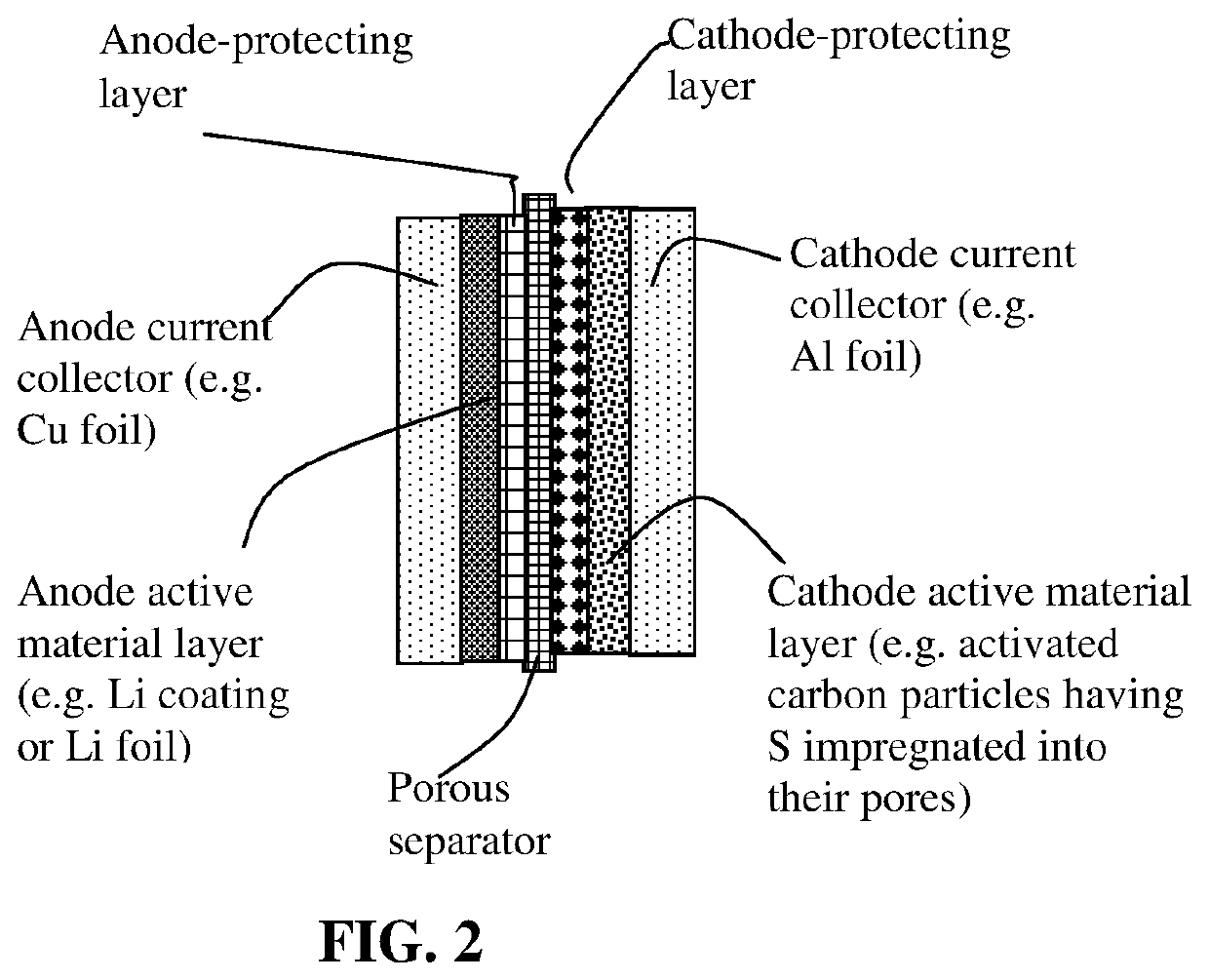

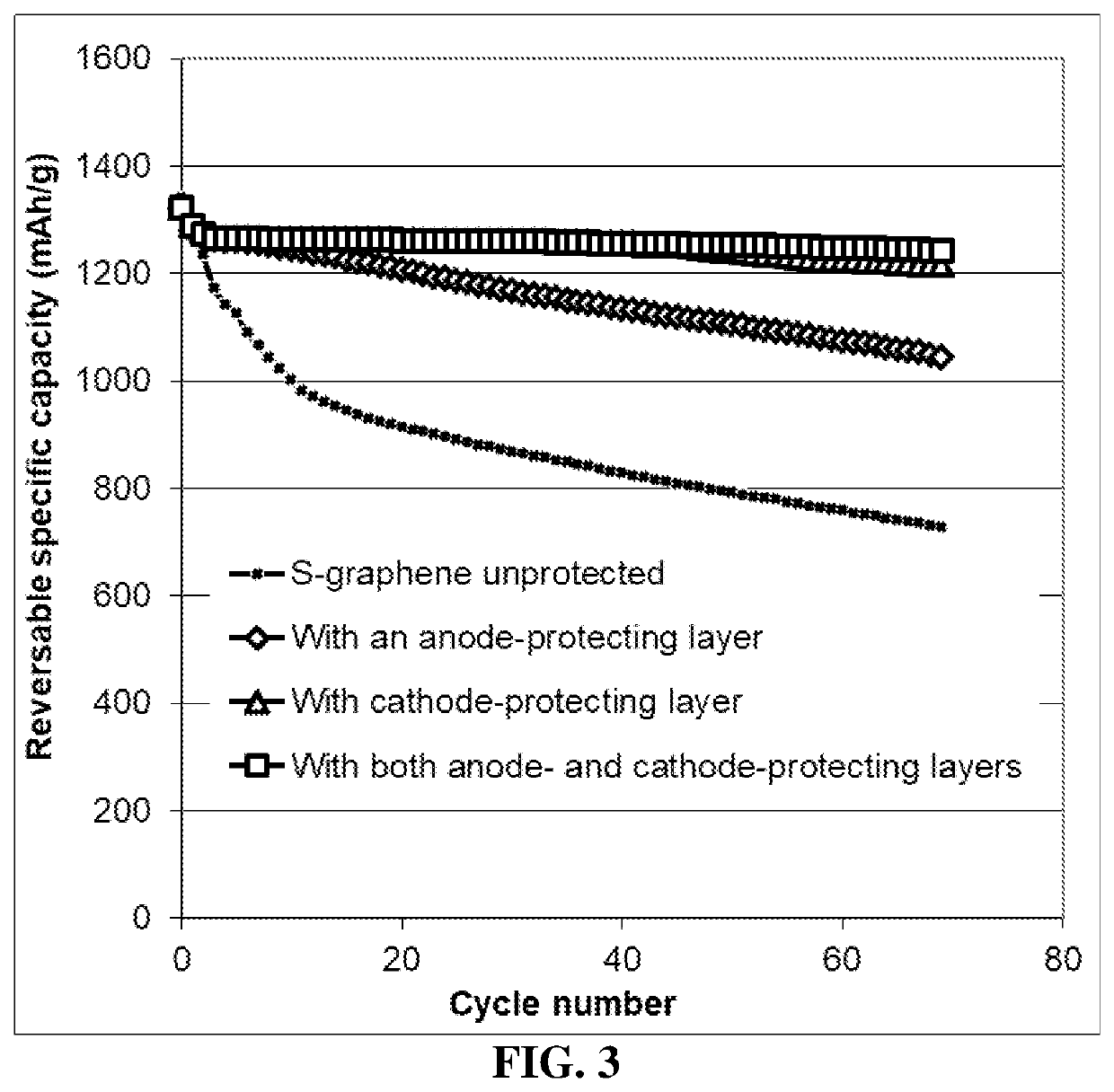

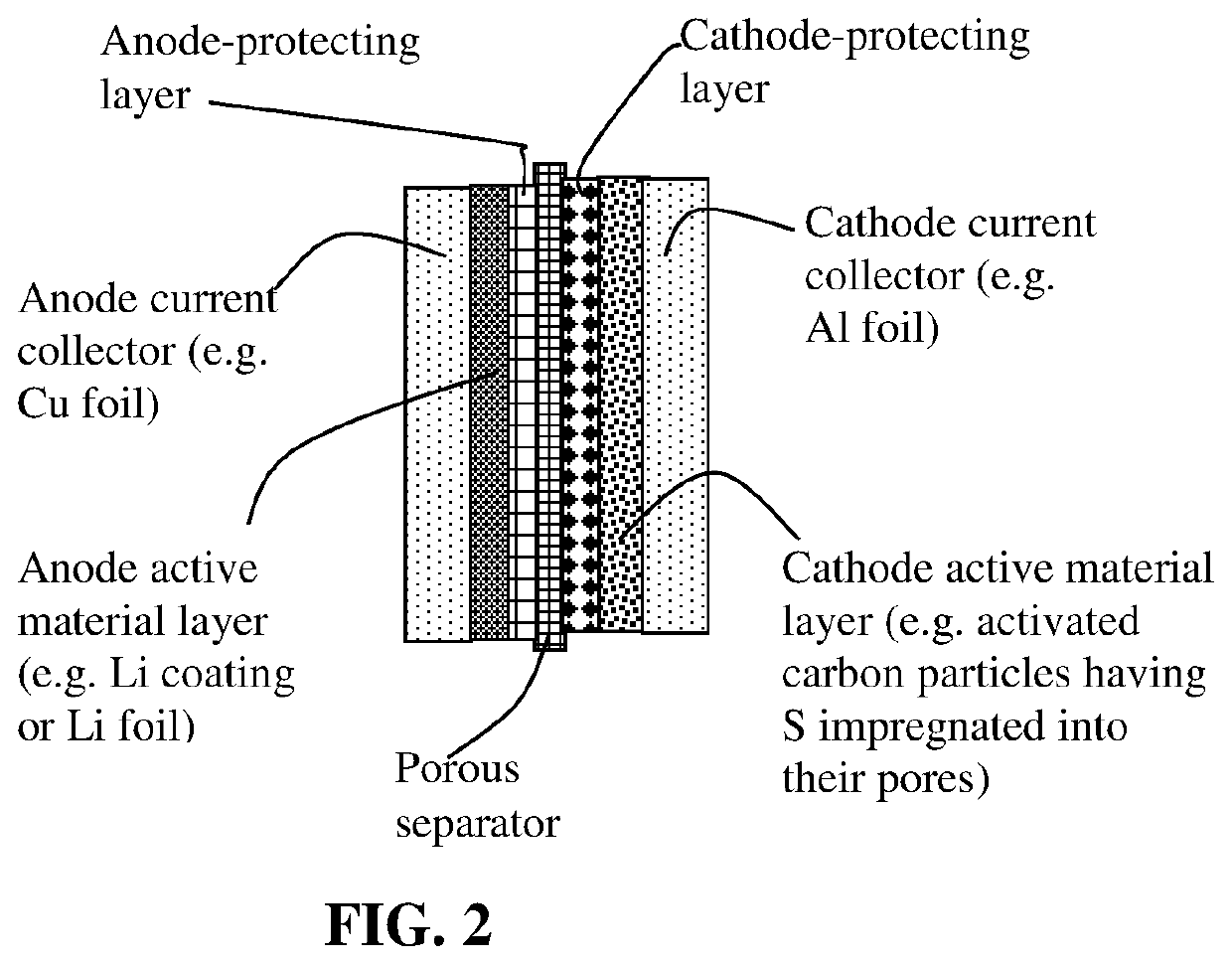

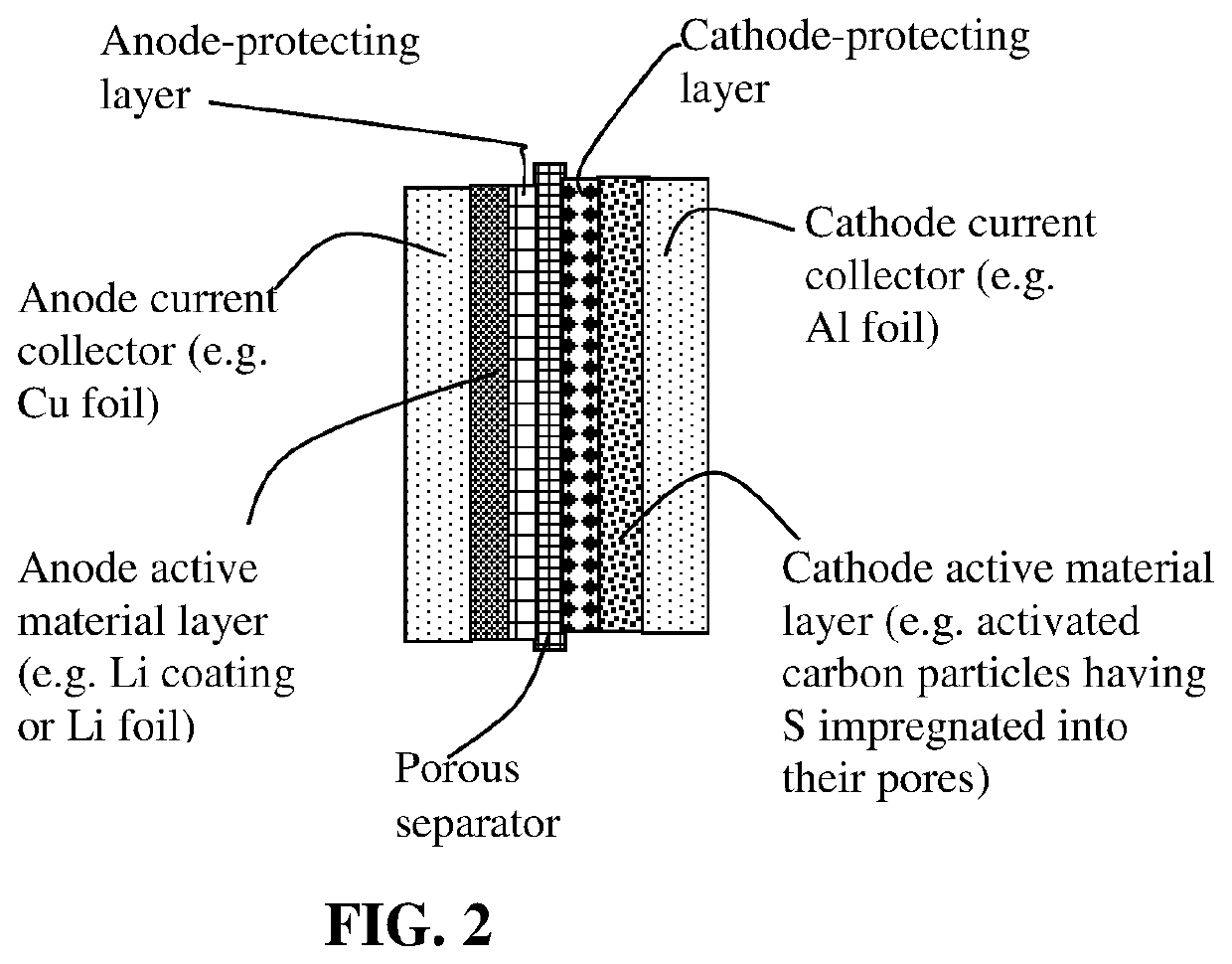

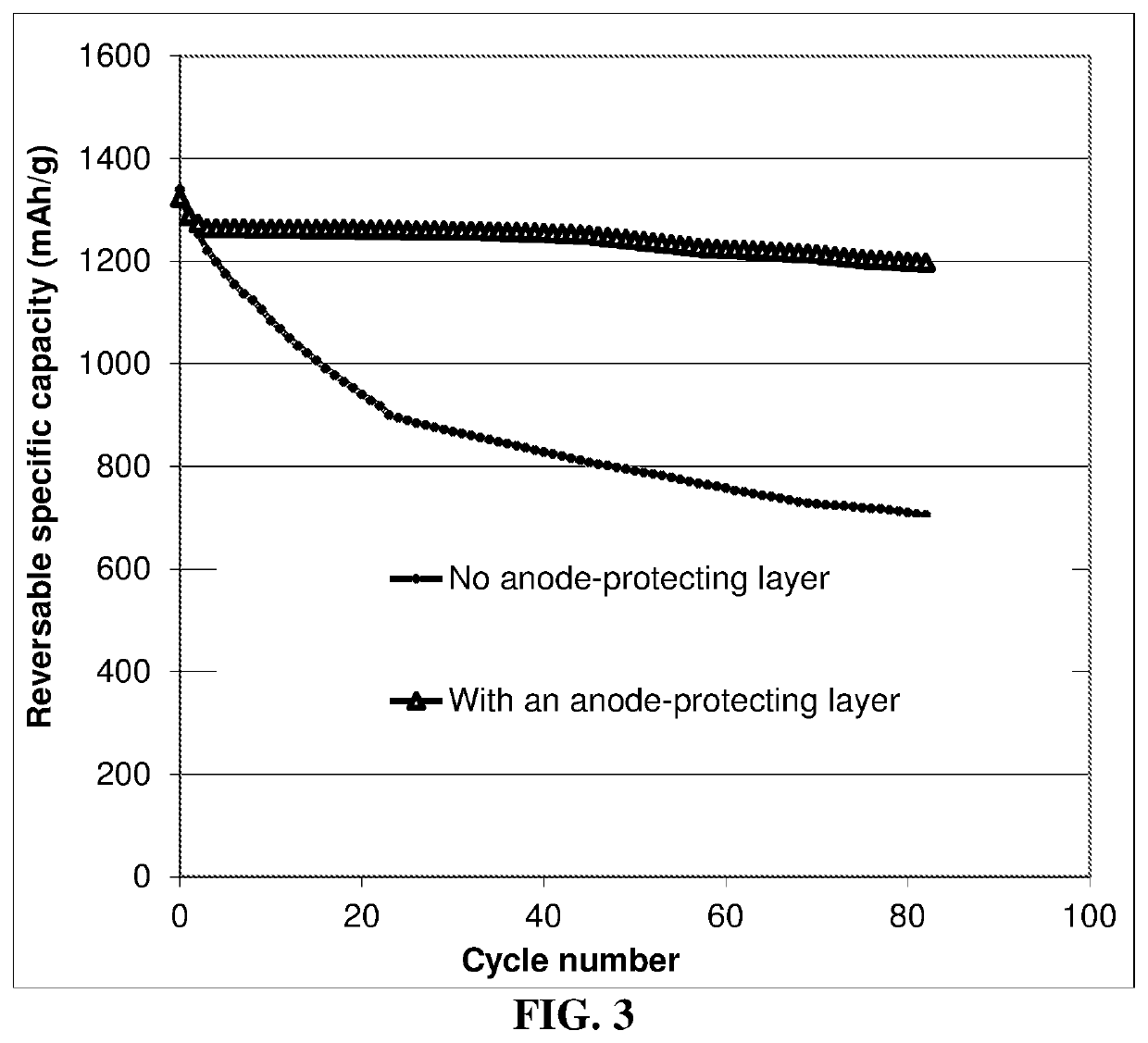

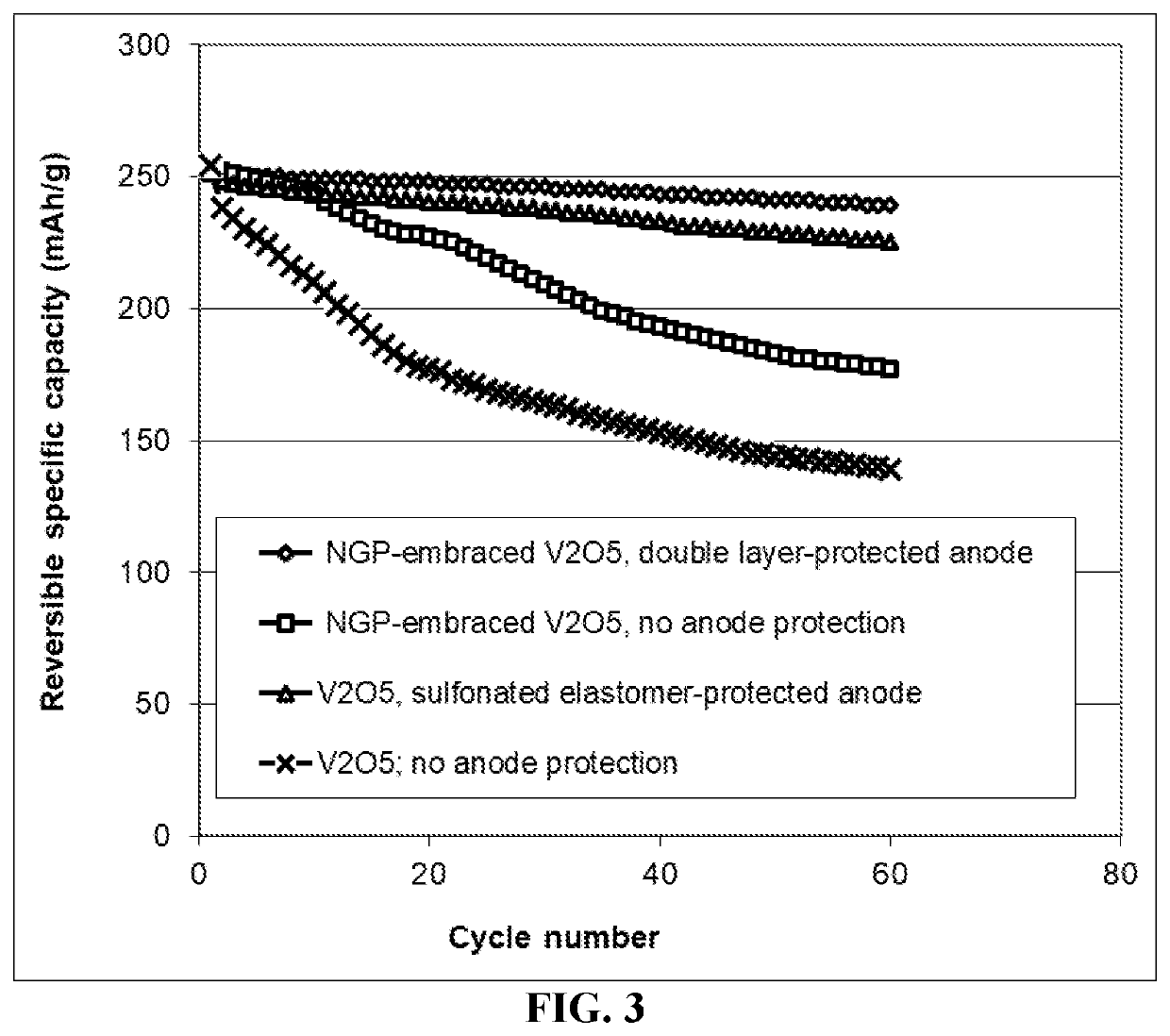

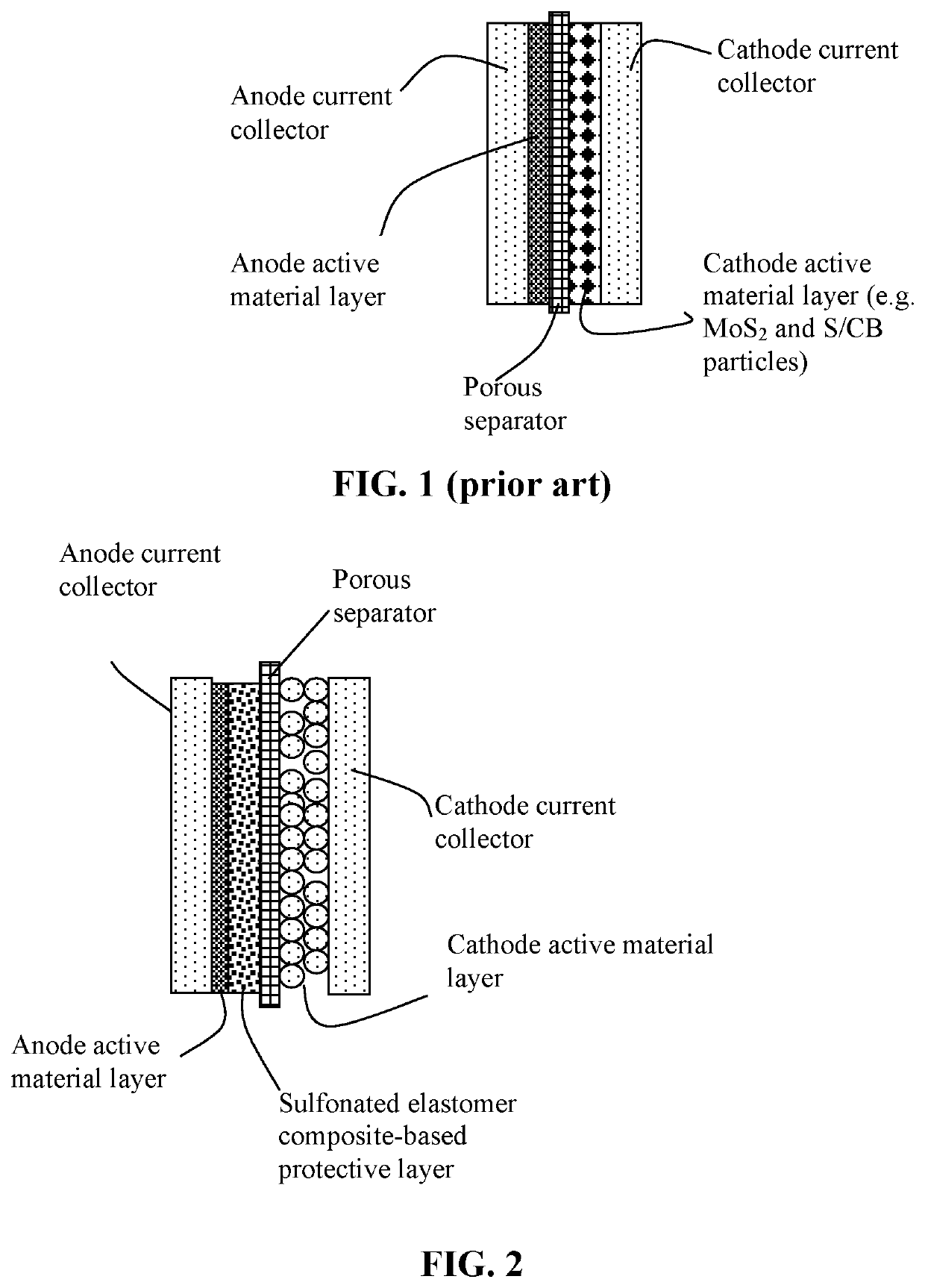

Alkali metal-sulfur secondary battery containing a conductive electrode- protecting layer

ActiveUS20190386332A1Reduces and eliminate shuttling effectReduce and eliminate effectCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsTensile strainHigh energy

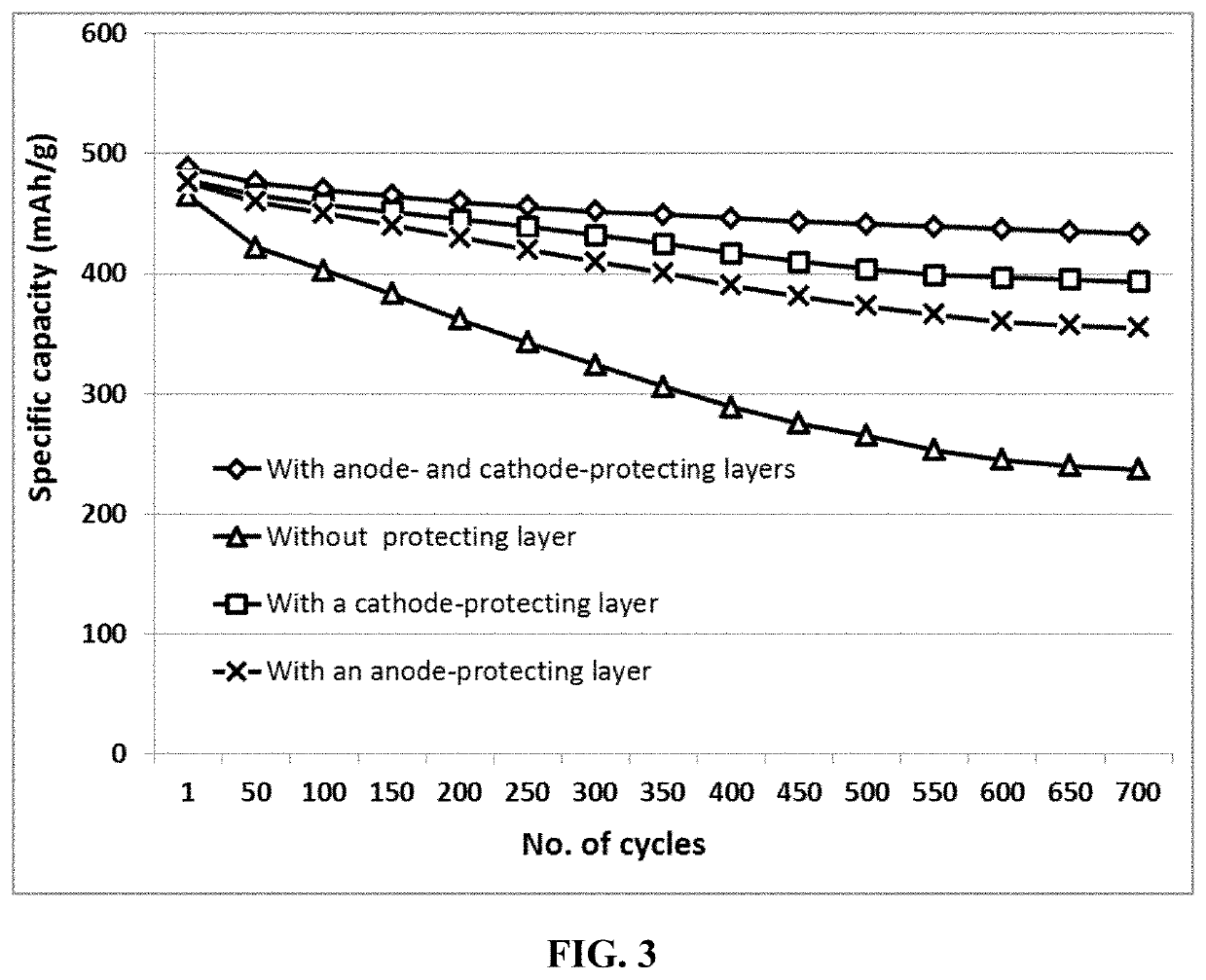

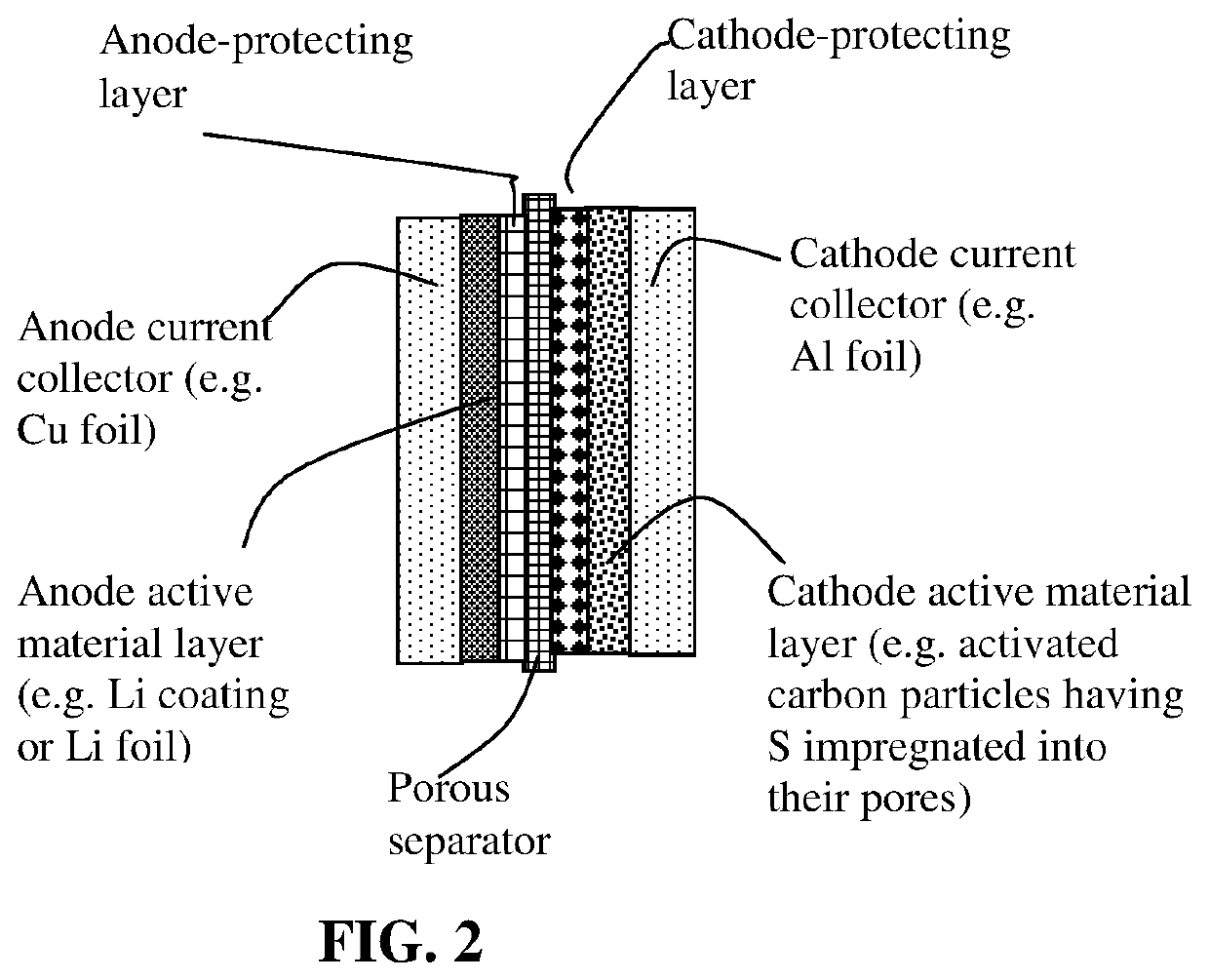

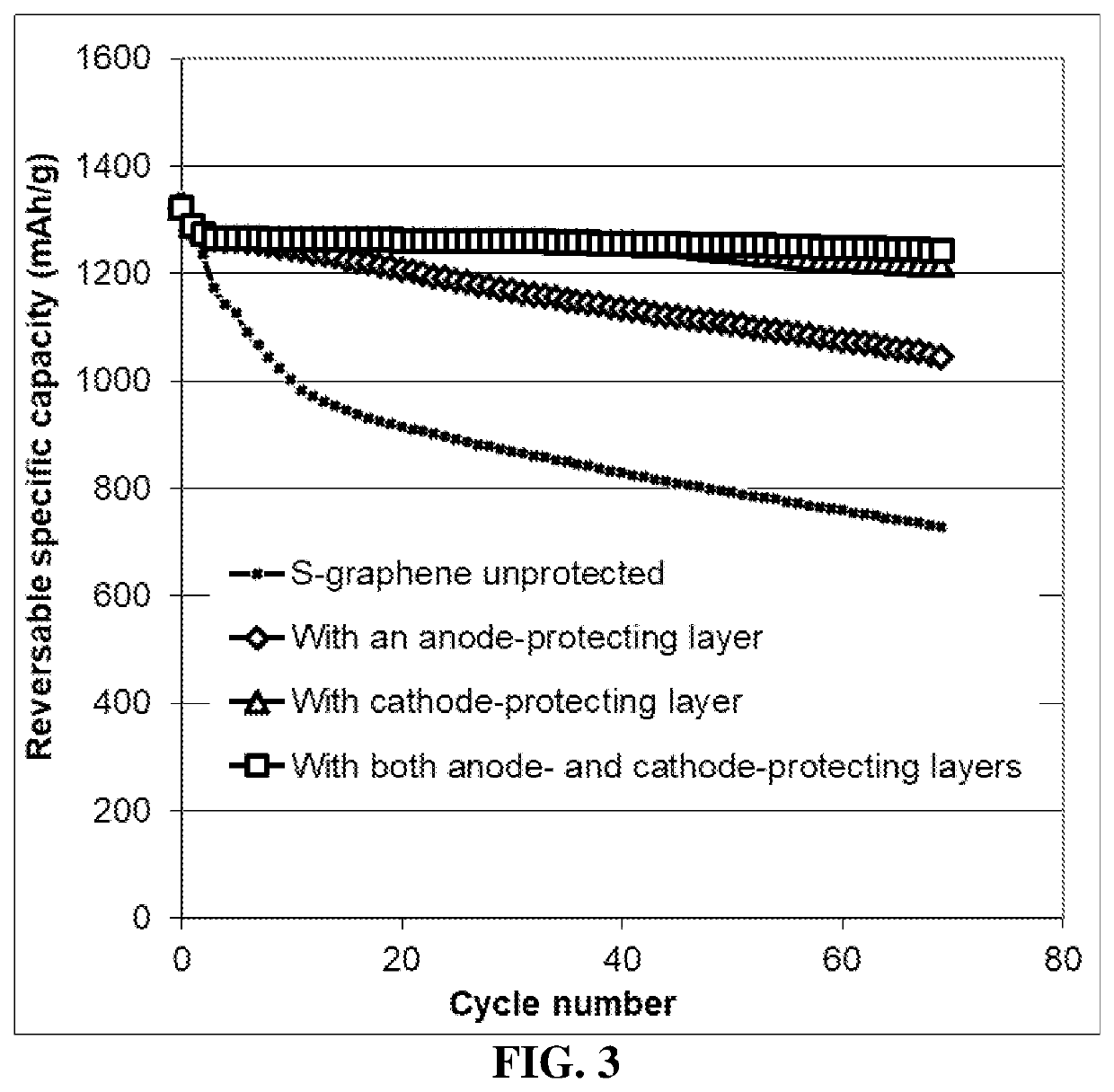

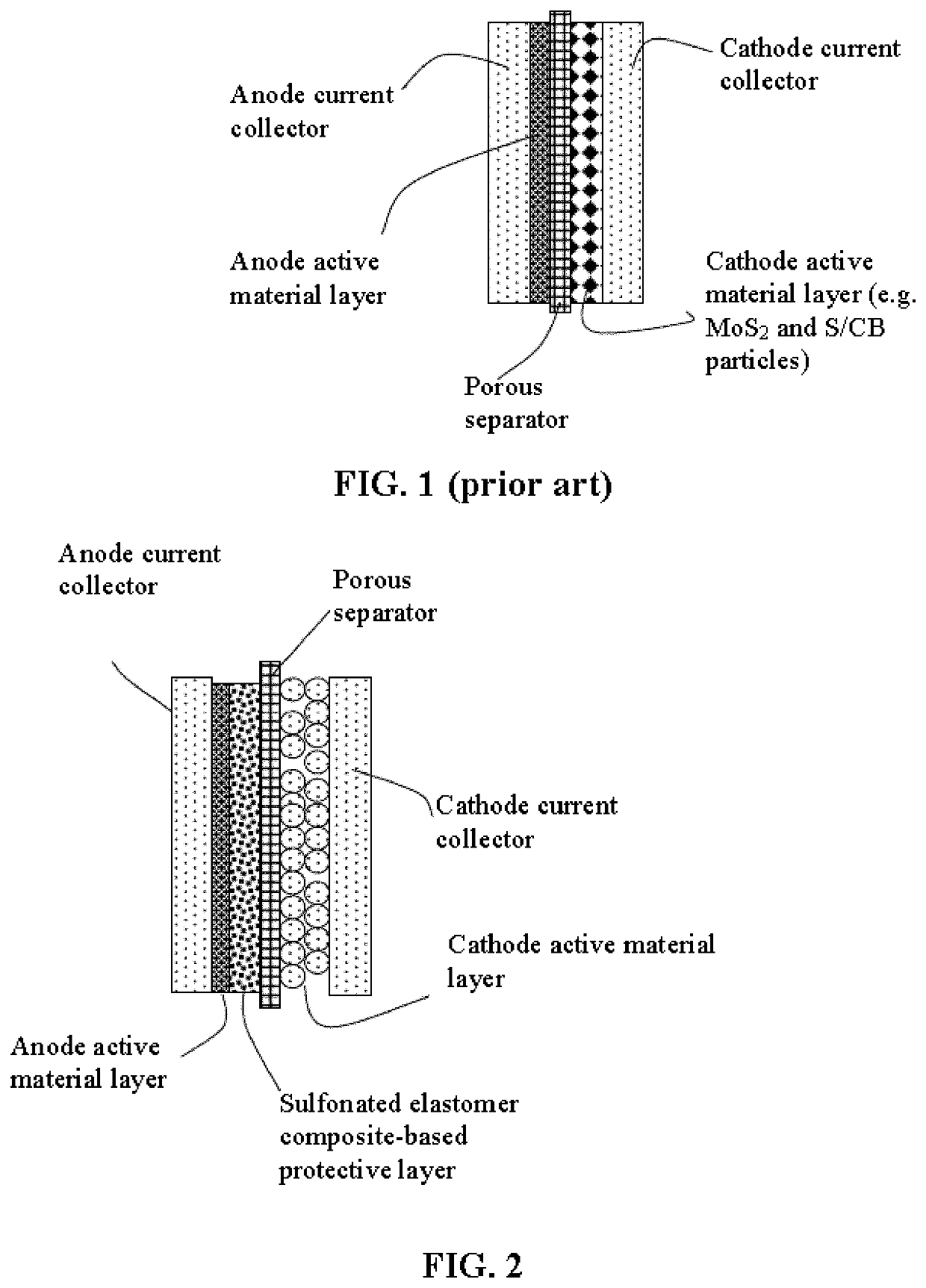

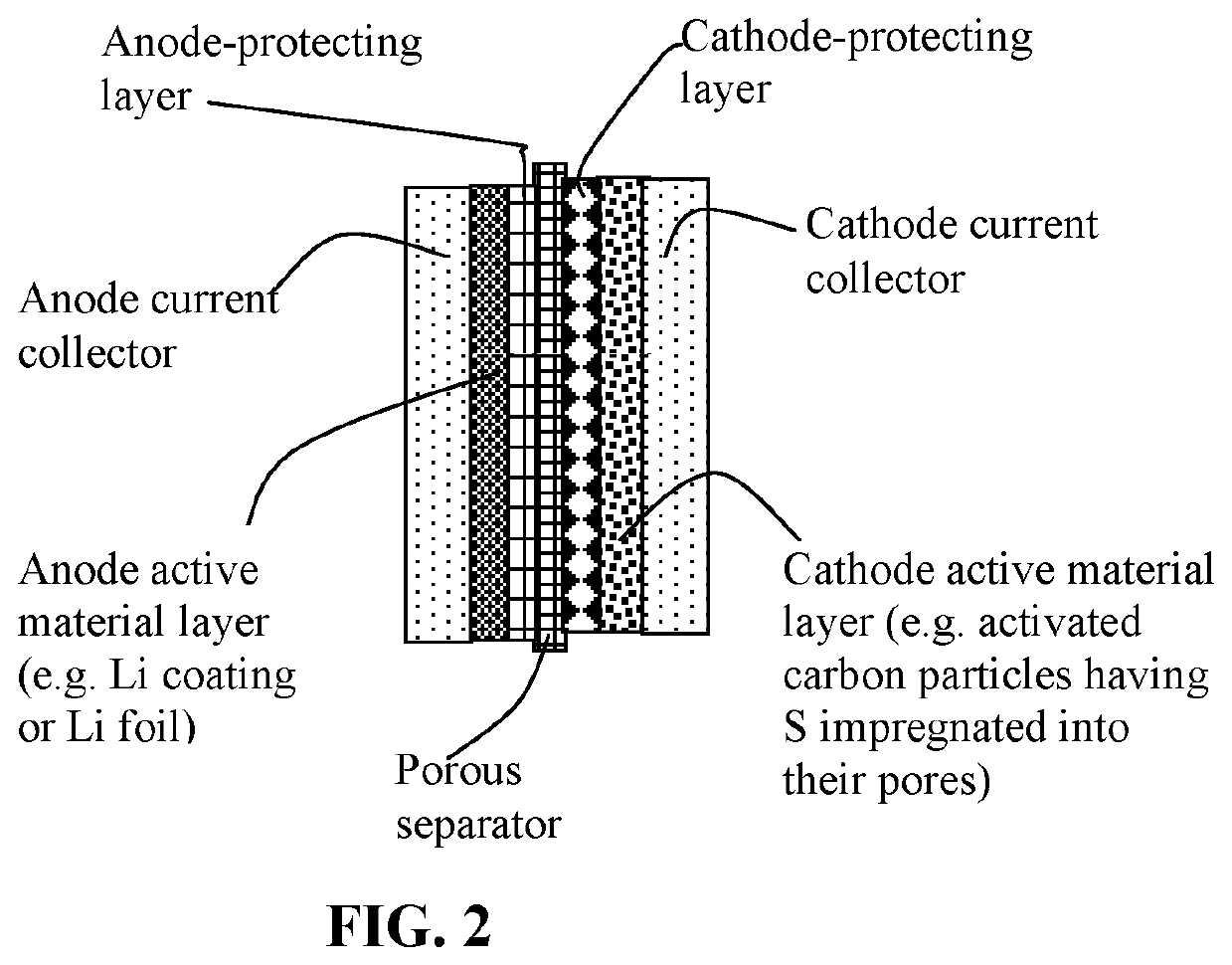

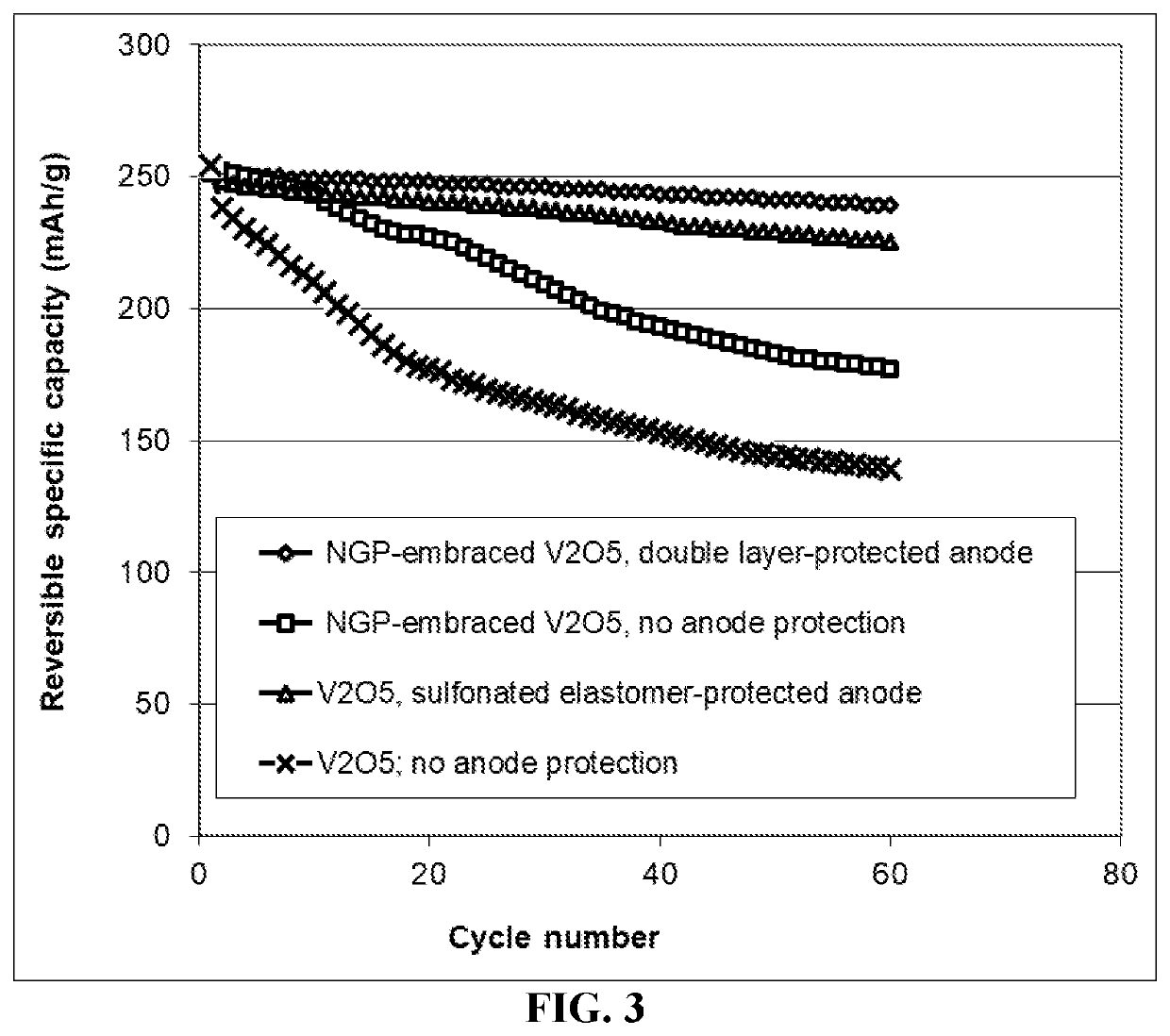

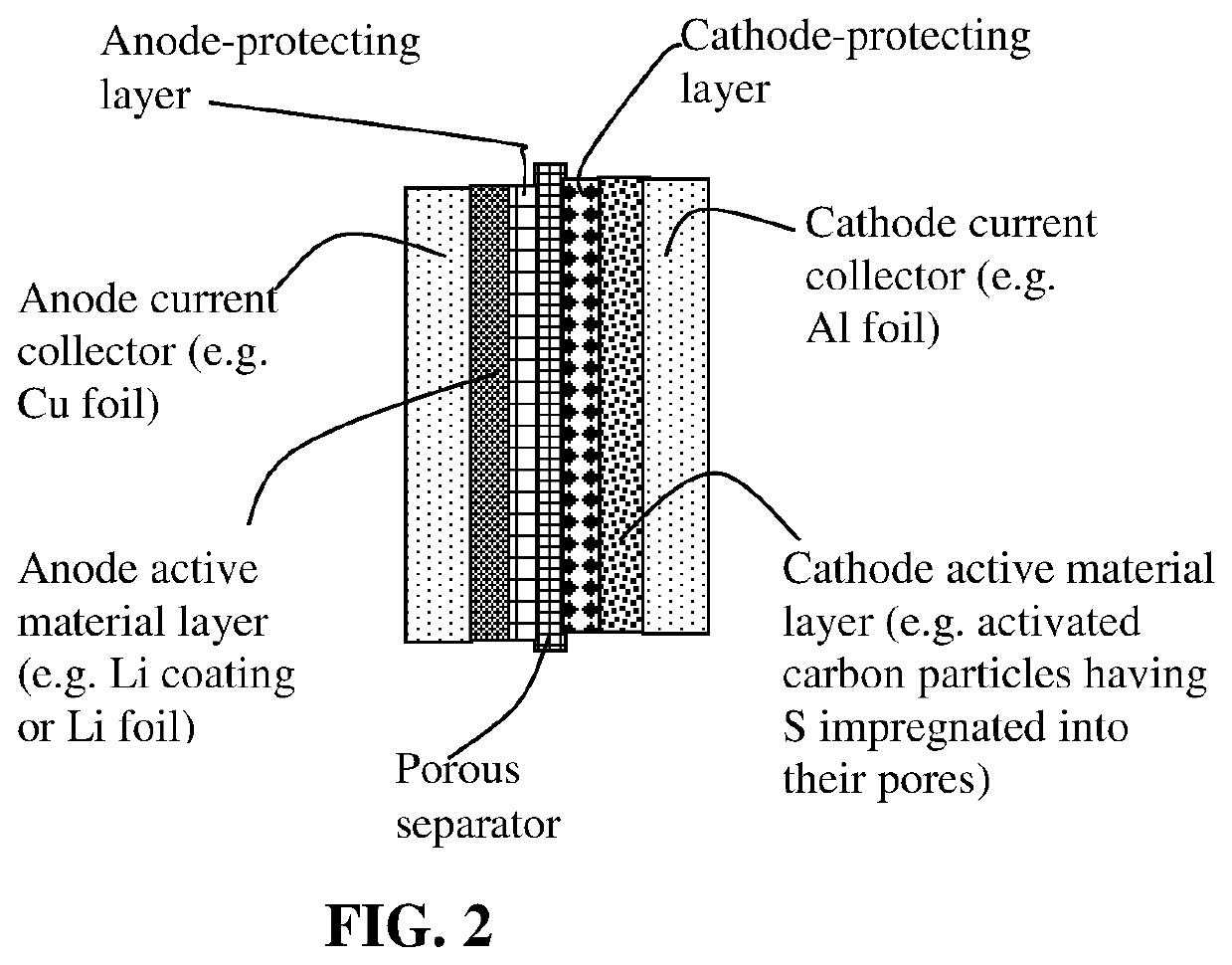

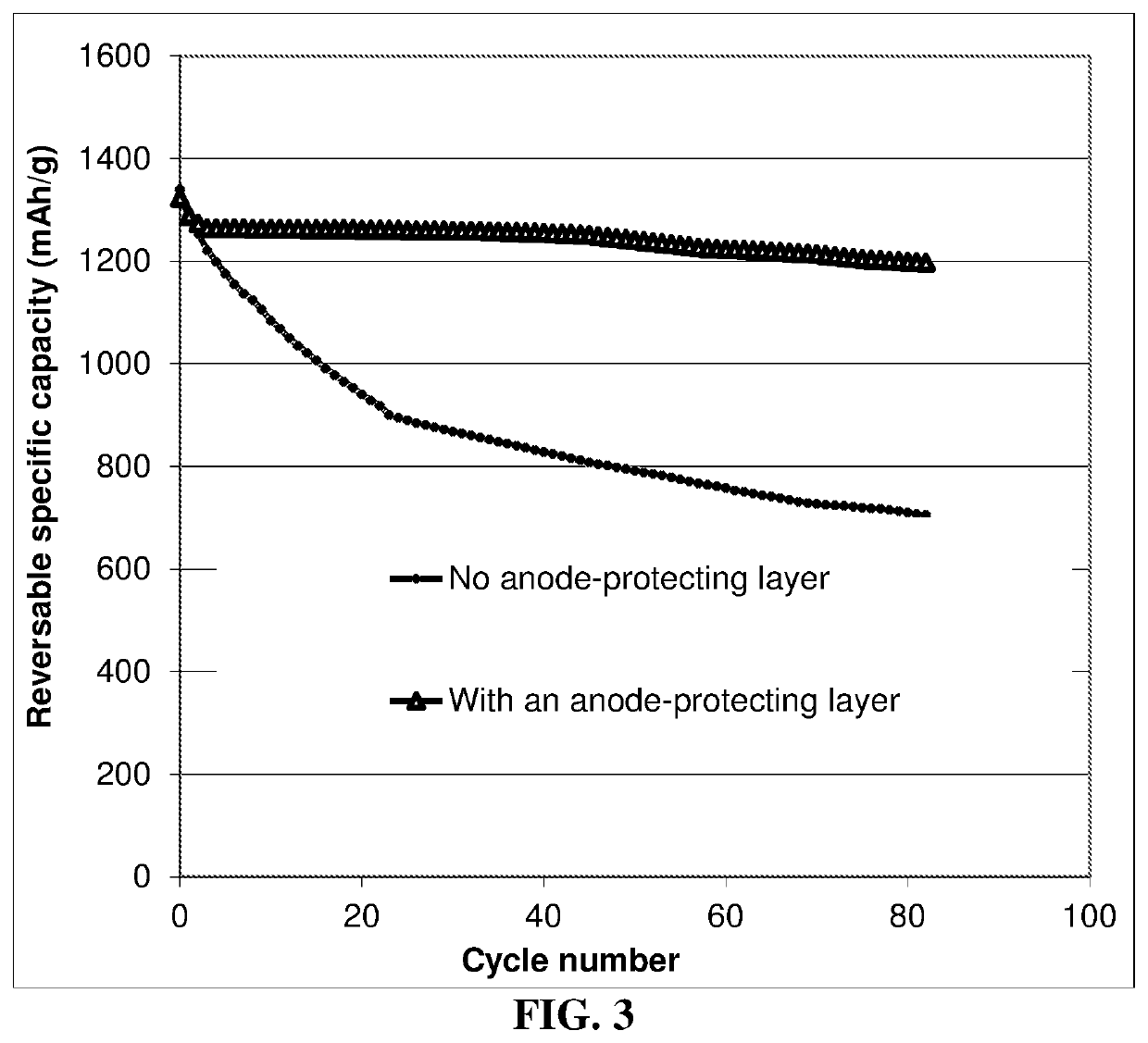

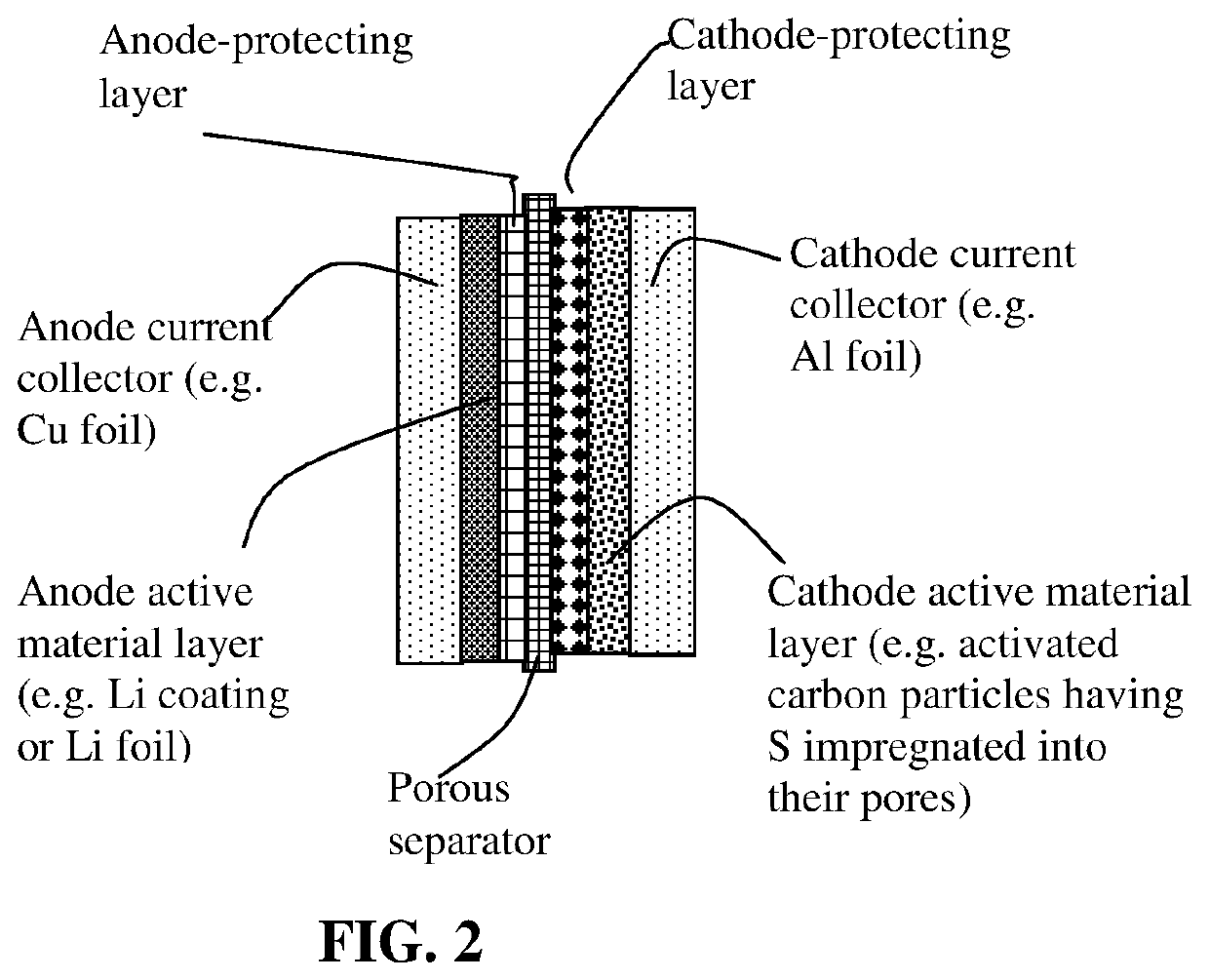

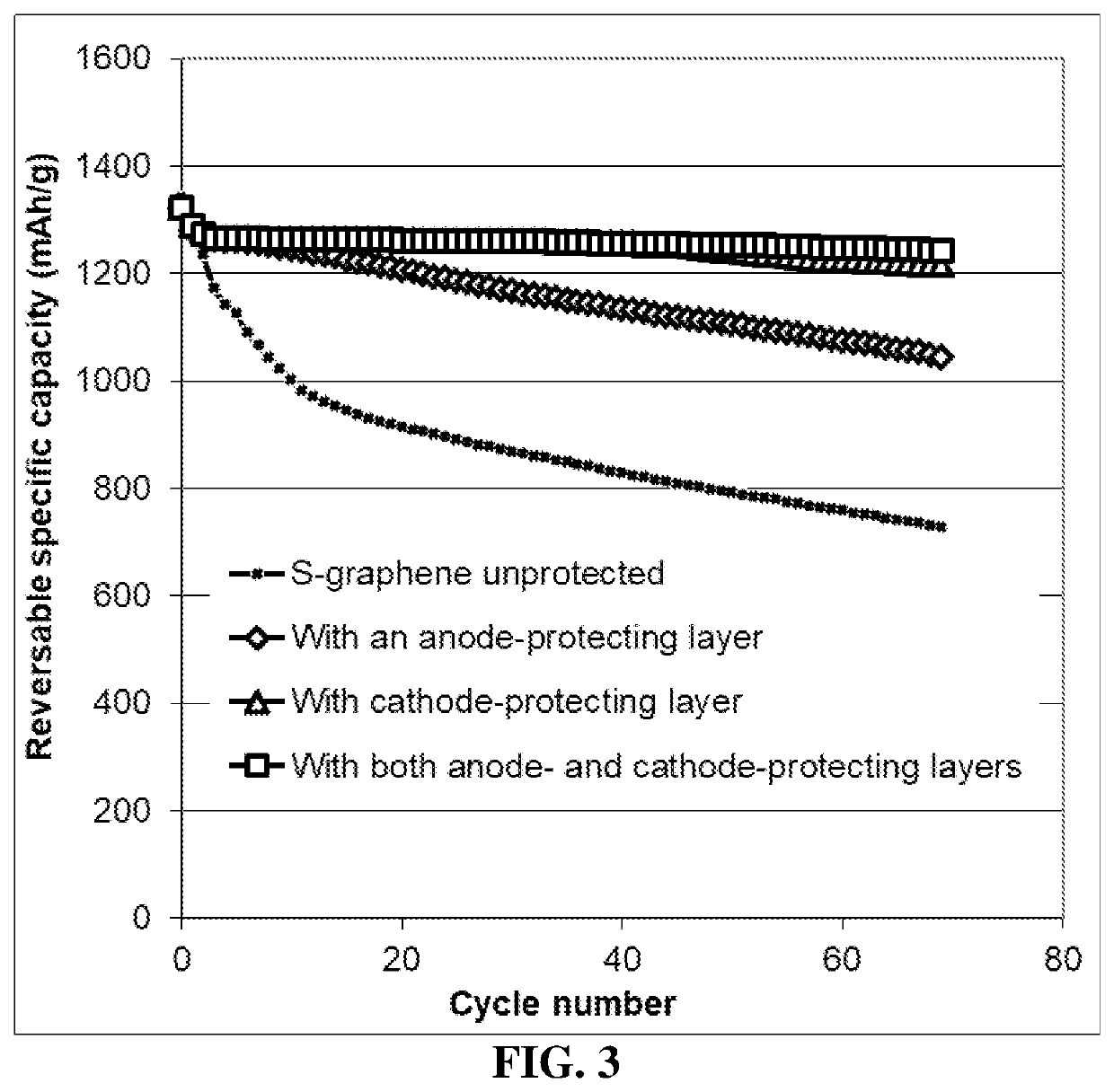

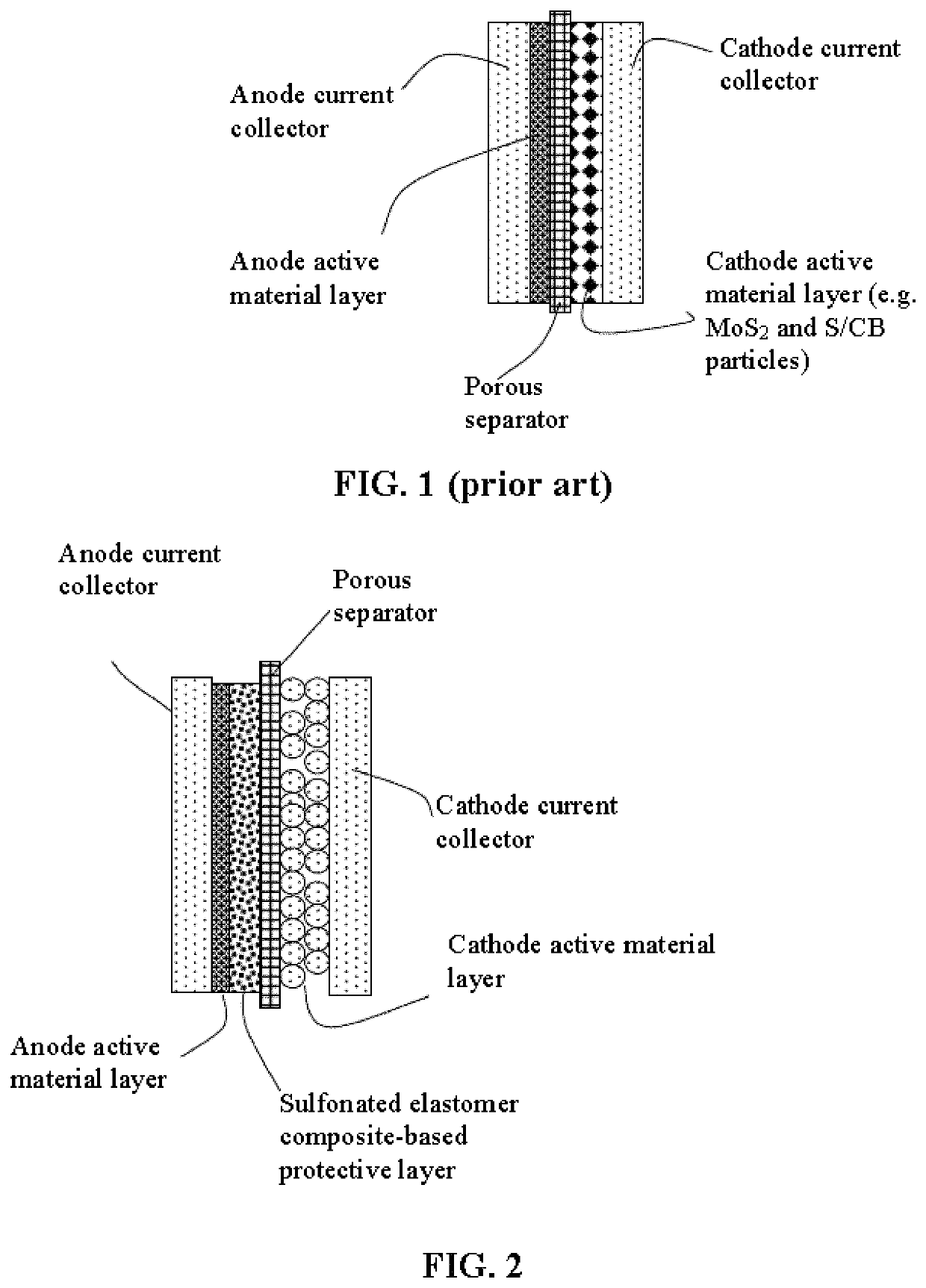

Provided is a rechargeable alkali metal-sulfur cell comprising an anode layer, an electrolyte and a porous separator, a cathode layer, and a discrete anode-protecting layer disposed between the anode layer and the separator and / or a discrete cathode-protecting layer disposed between the separator and the cathode active material layer; wherein the anode-protecting layer or cathode-protecting layer comprises a conductive sulfonated elastomer composite having from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material and the protective layer has a thickness from 1 nm to 50 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

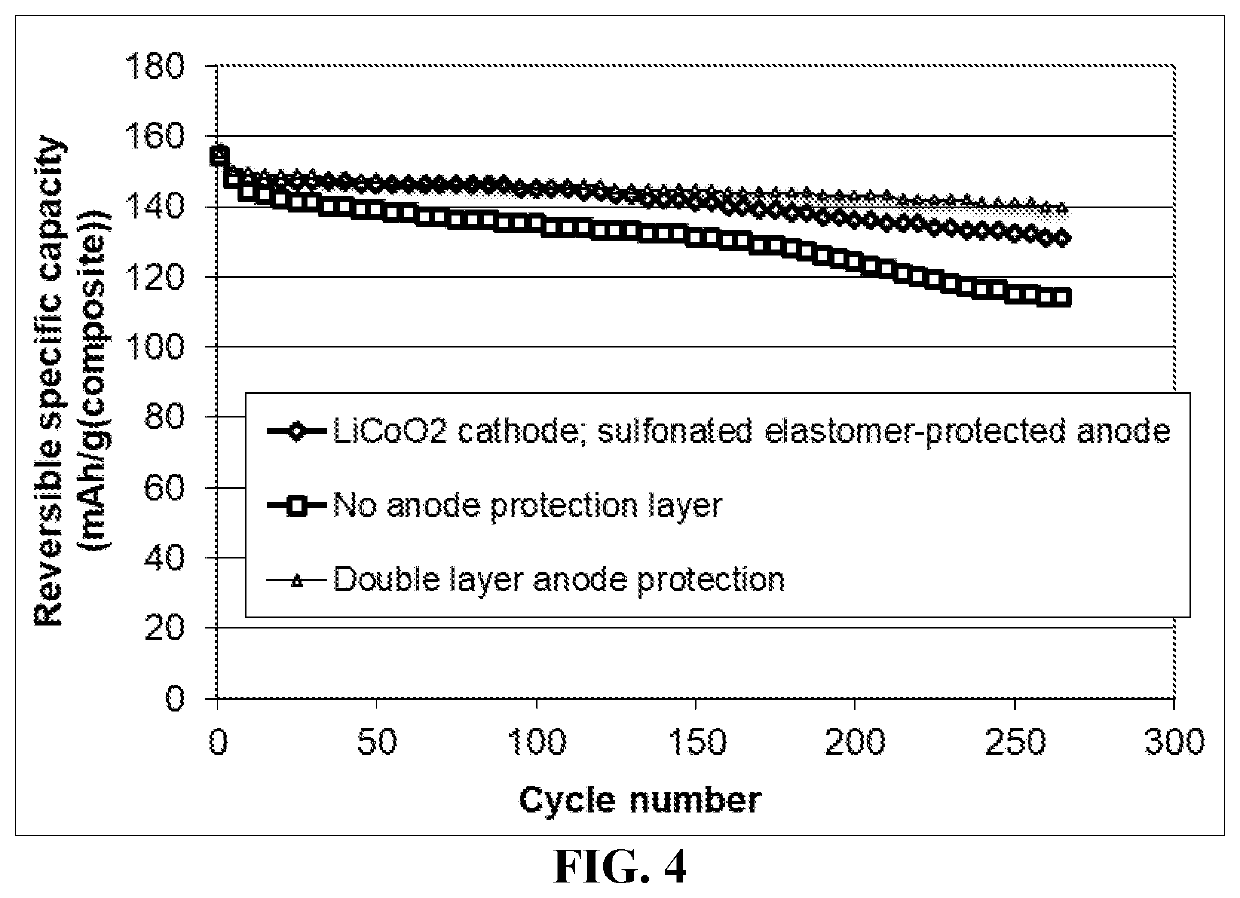

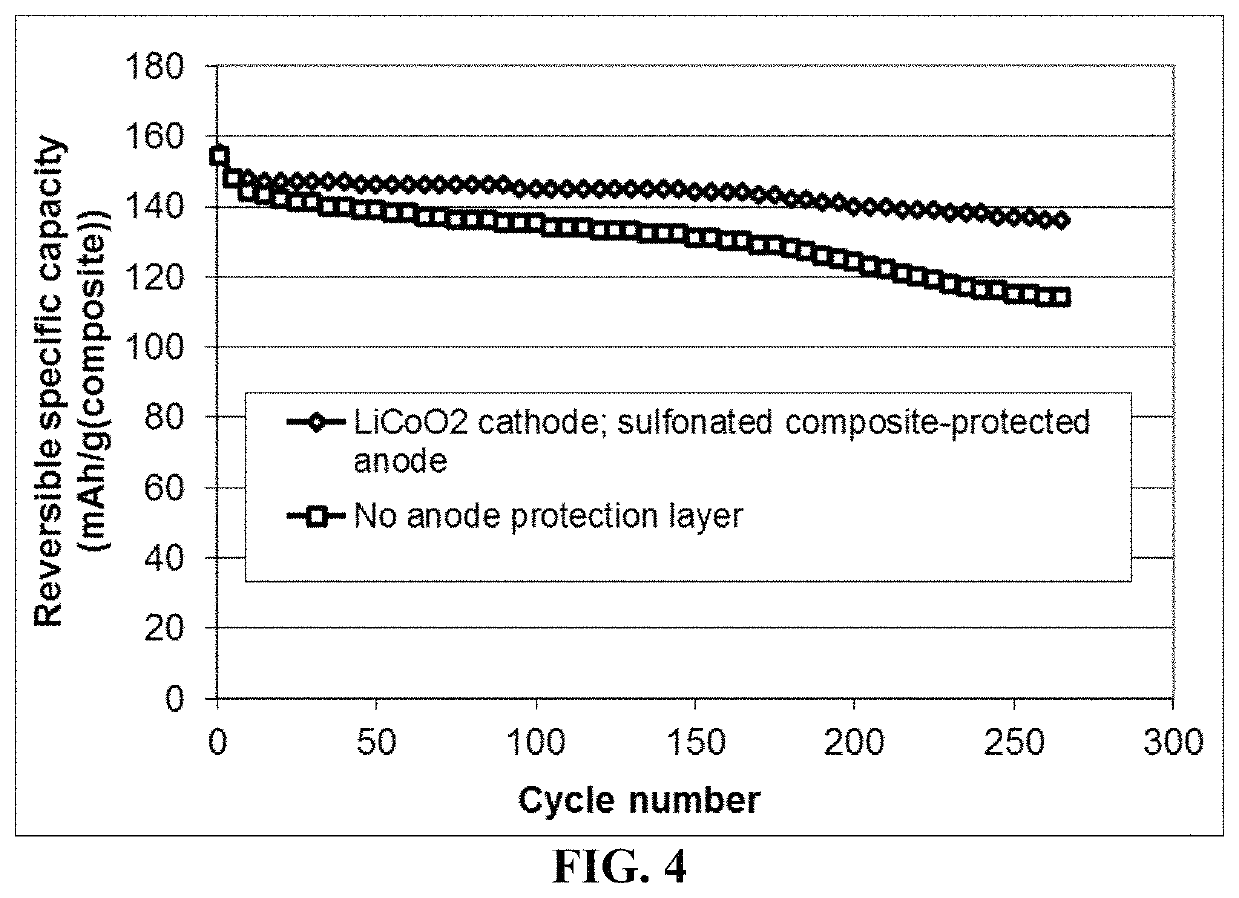

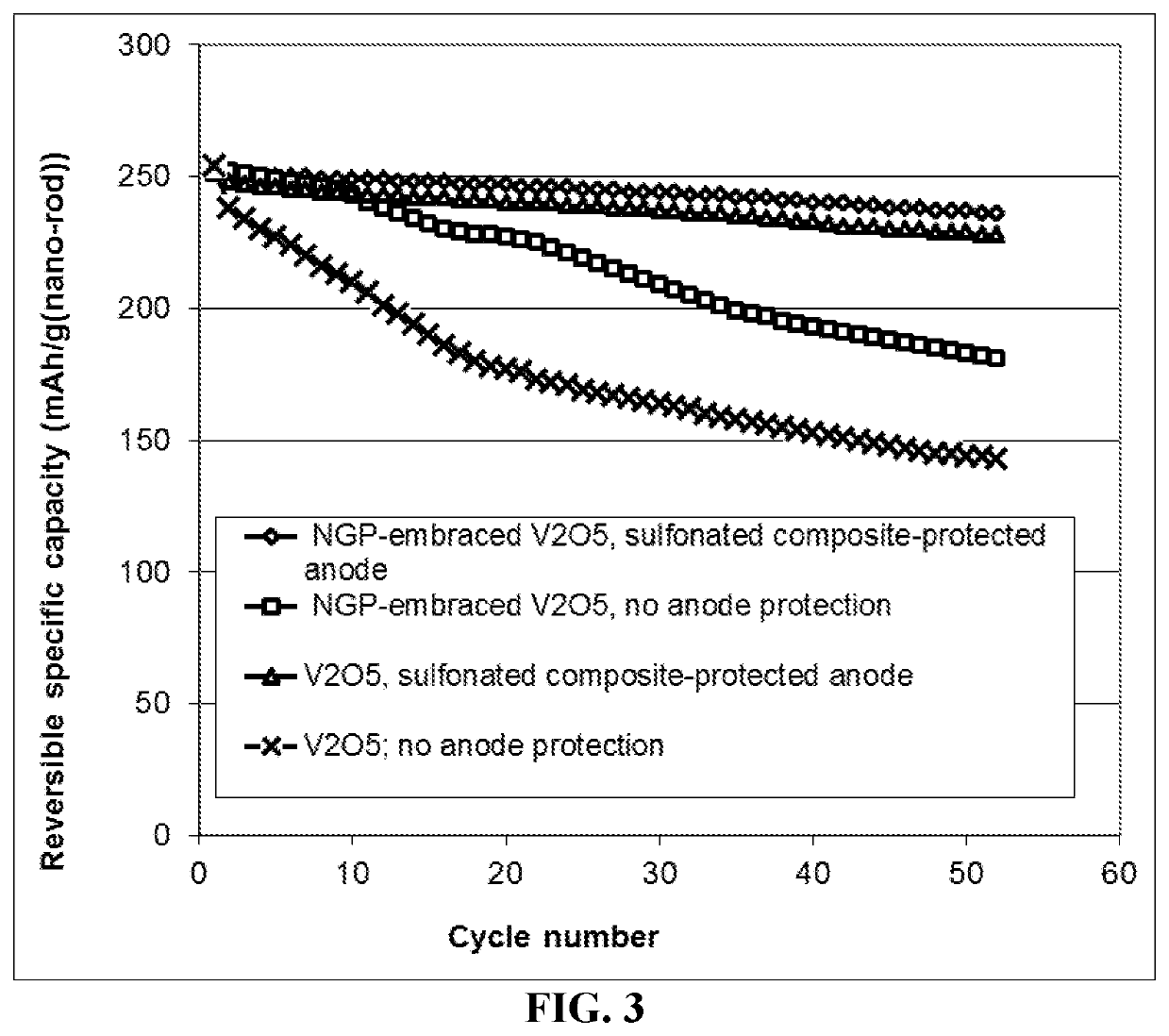

Lithium metal secondary battery containing an electrochemically stable anode-protecting layer

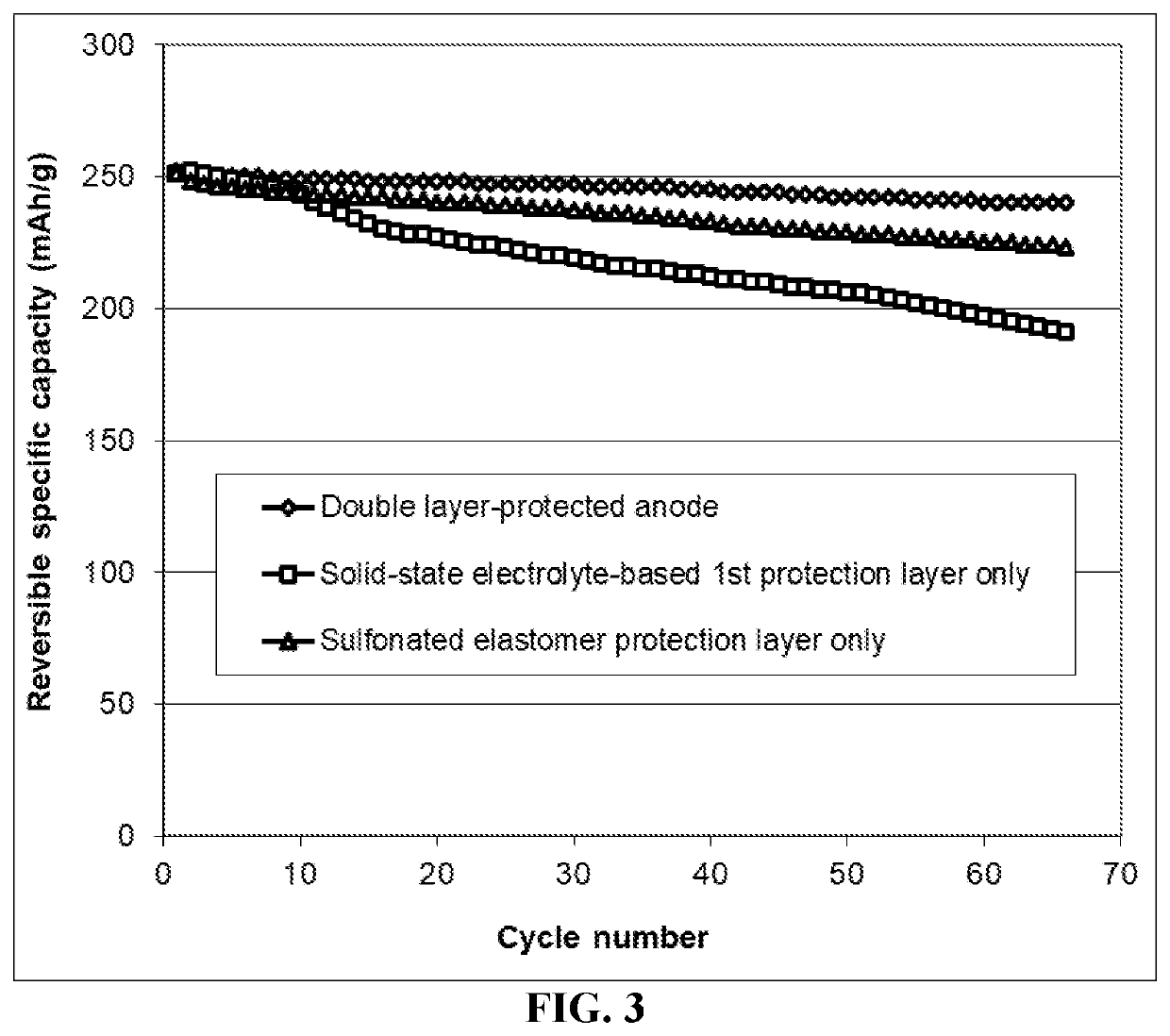

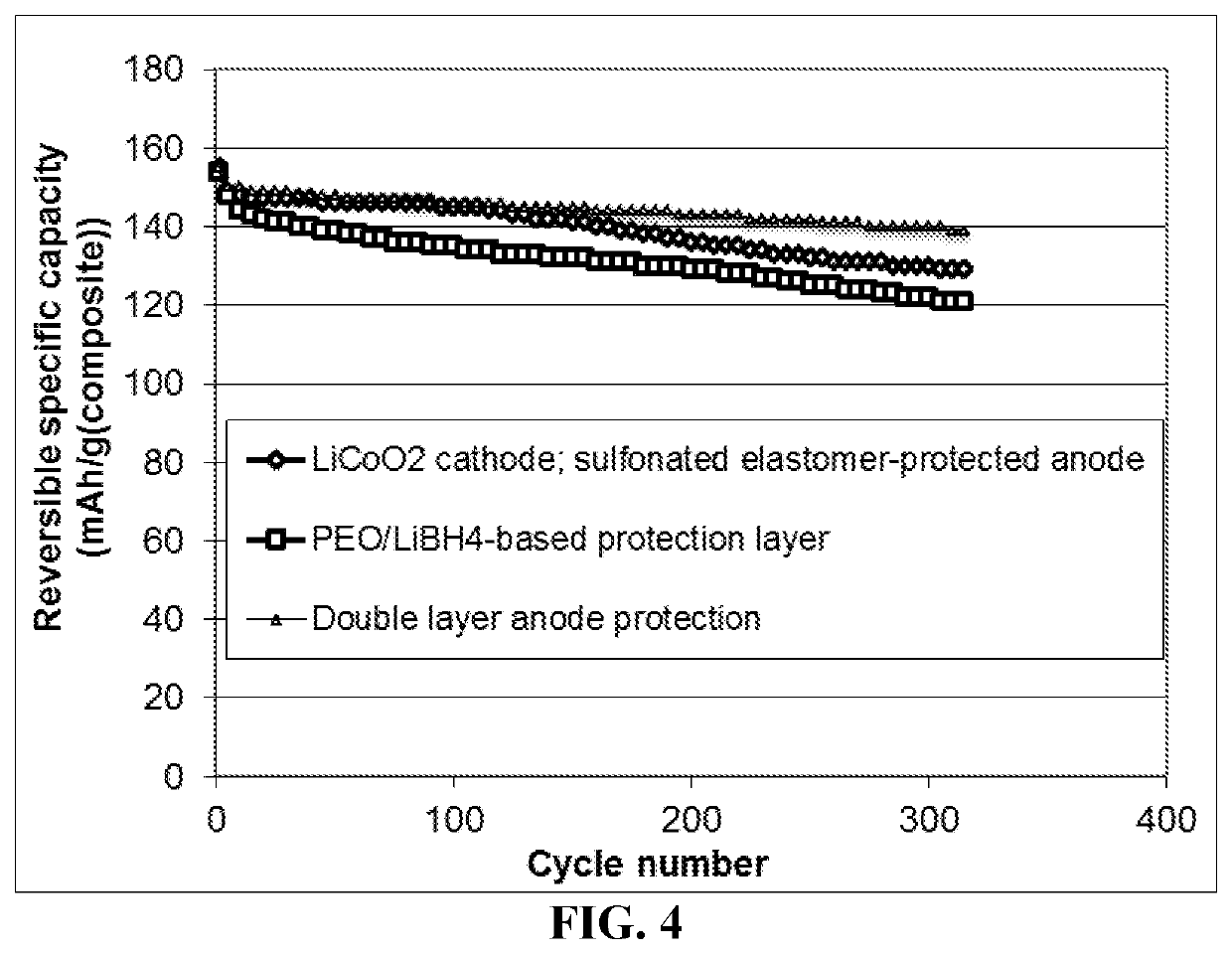

ActiveUS20190393495A1Reduce eliminatePromotes uniform depositionNegative electrodesPositive electrodesElectrical batteryLithium metal

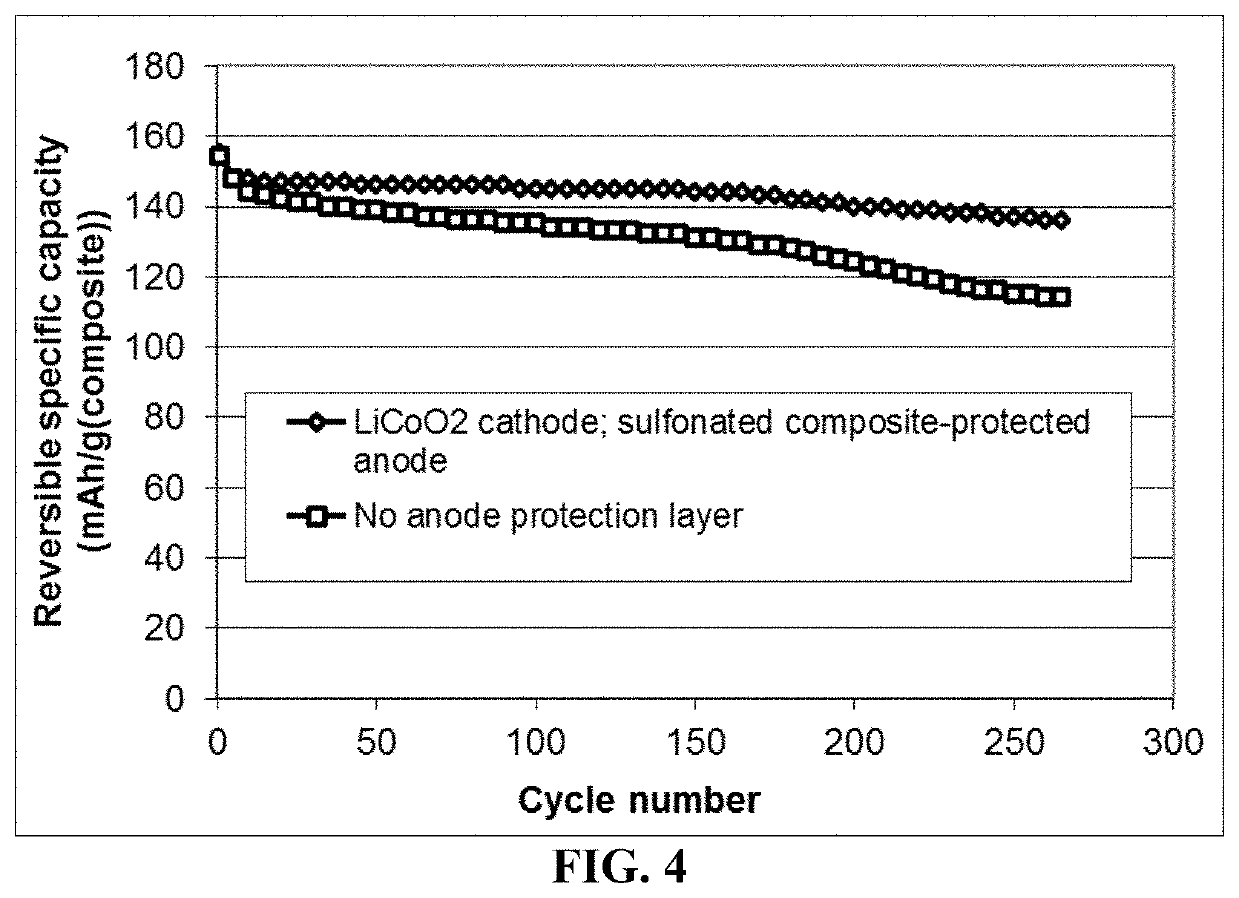

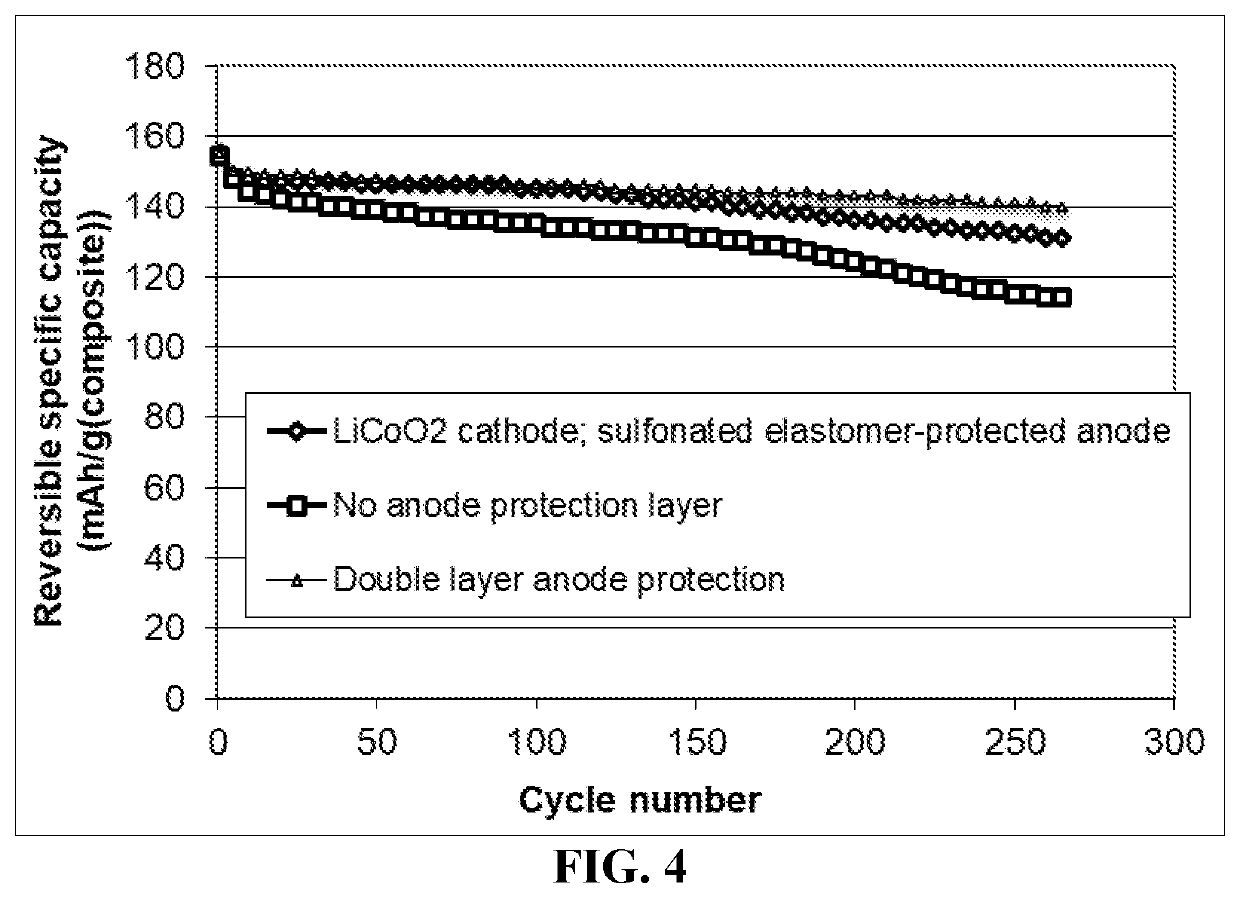

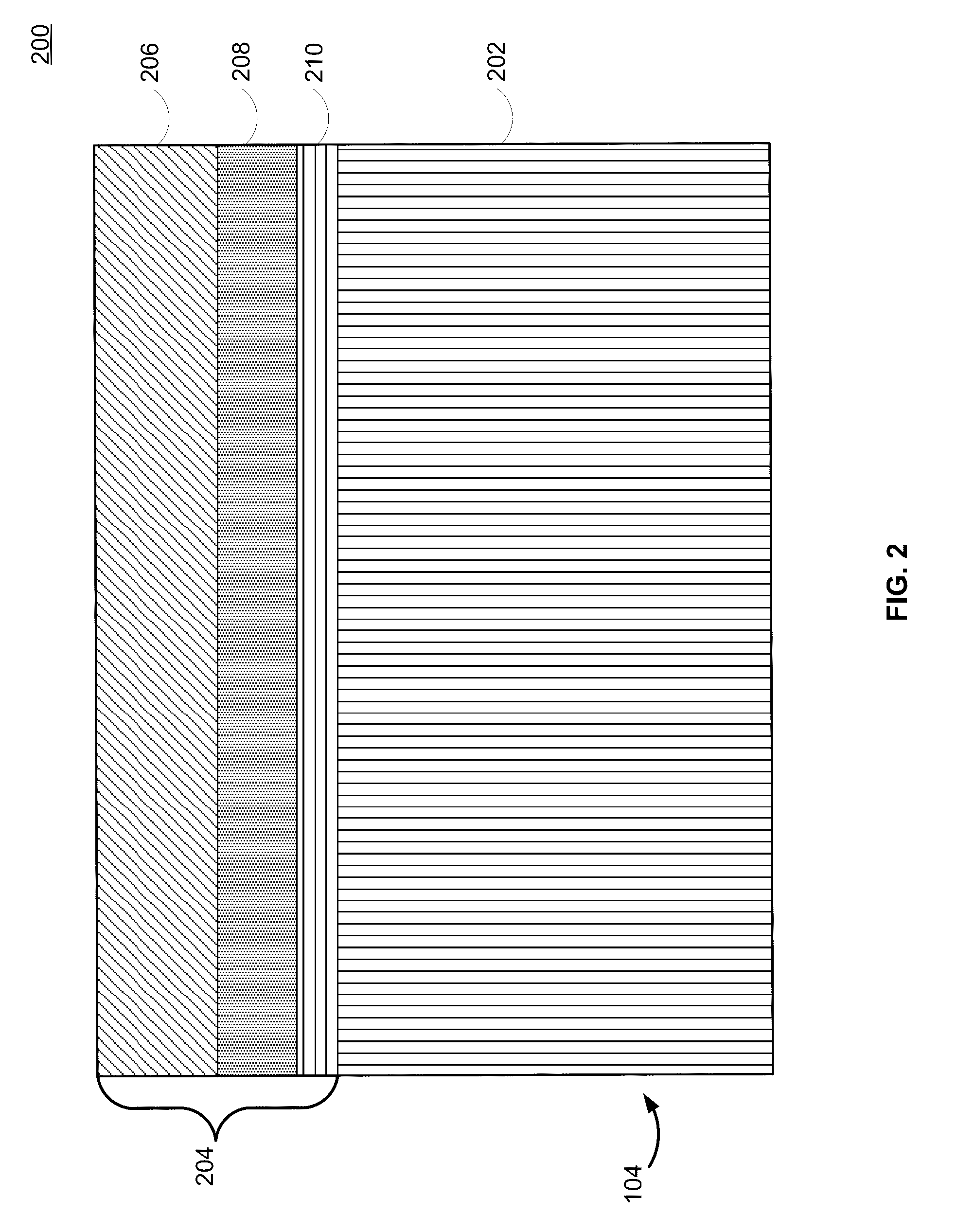

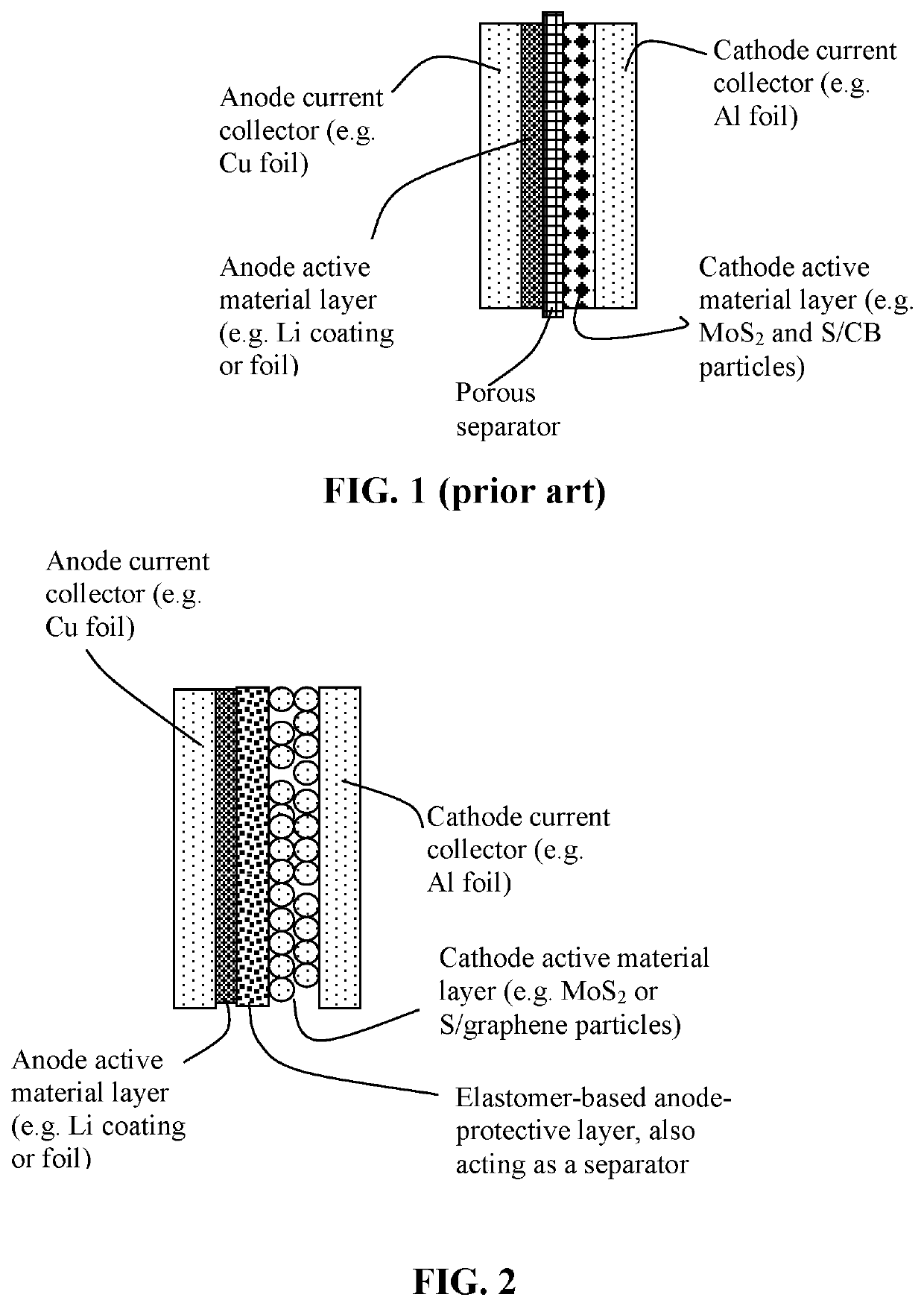

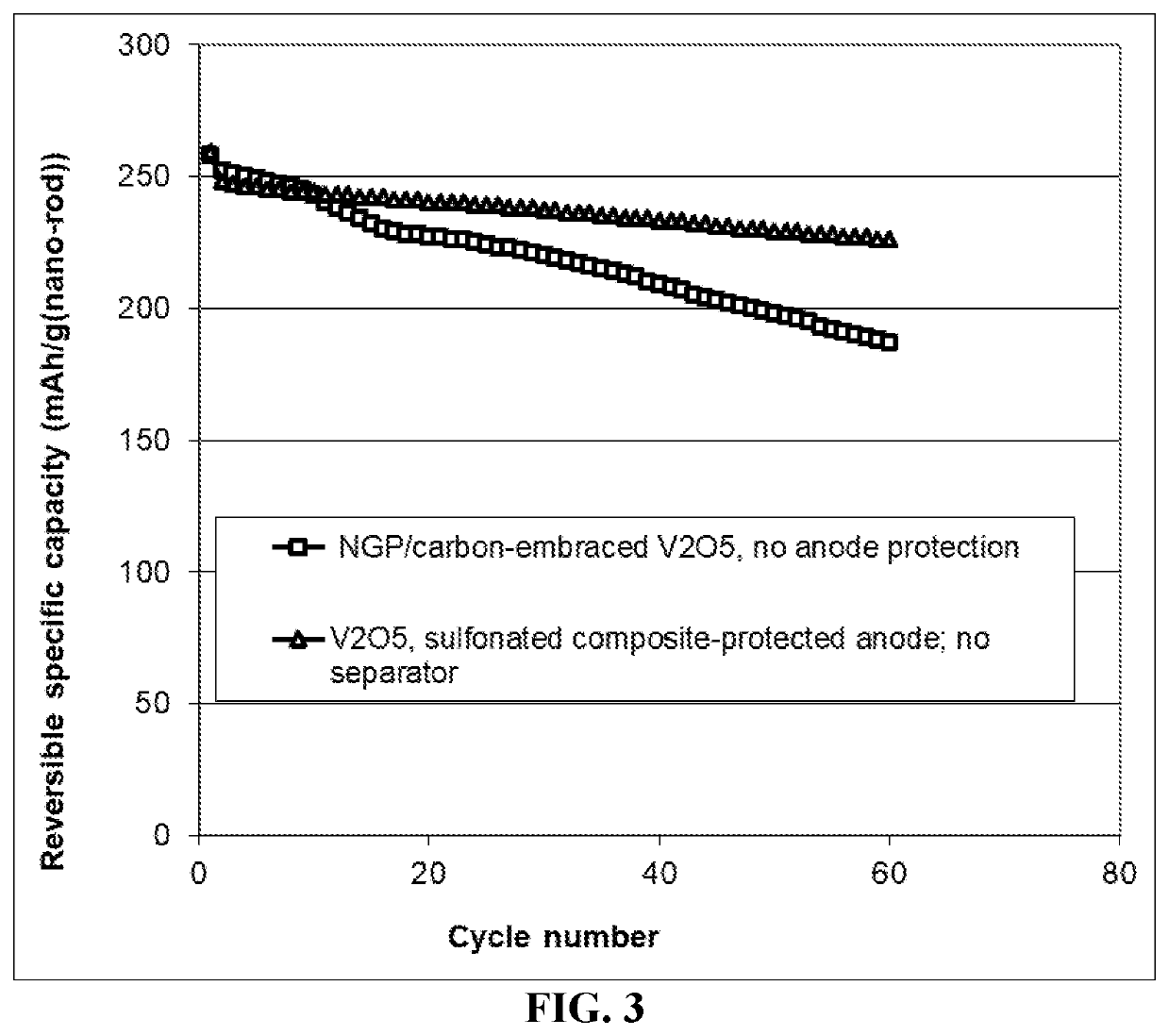

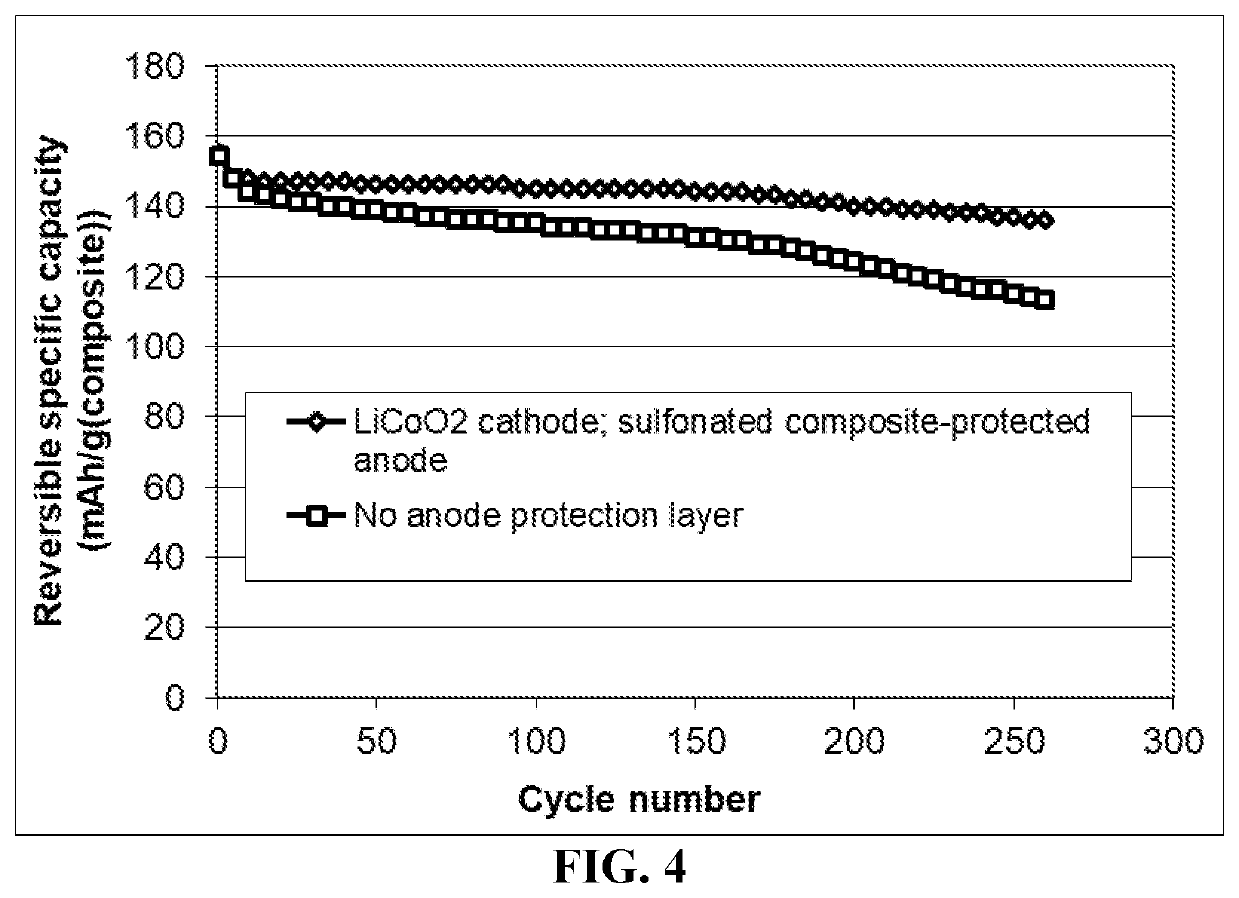

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; and (b) an anode-protecting layer of a conductive sulfonated elastomer composite, disposed between the anode active layer and the separator / electrolyte; wherein the composite has from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an inorganic filler dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

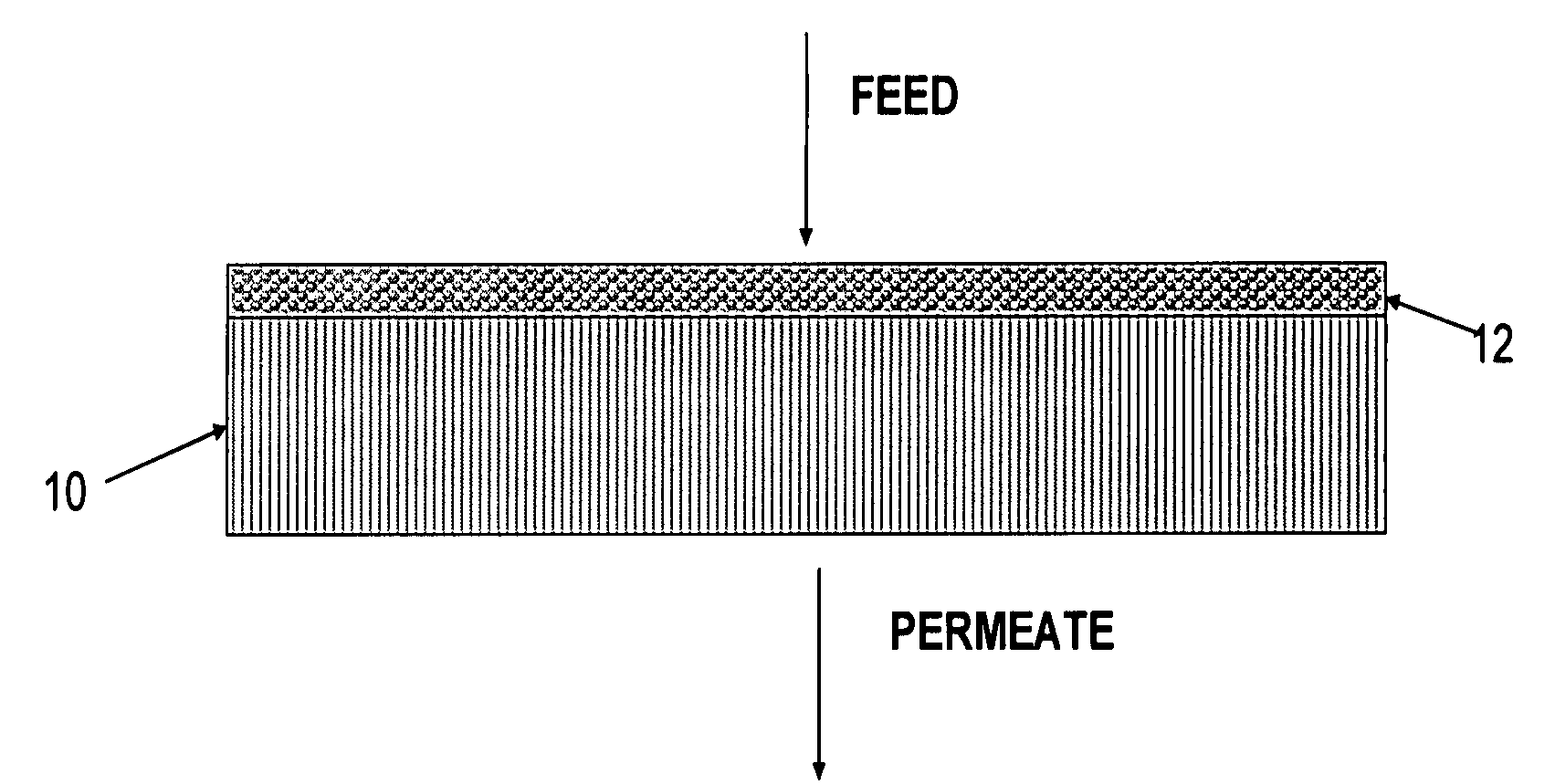

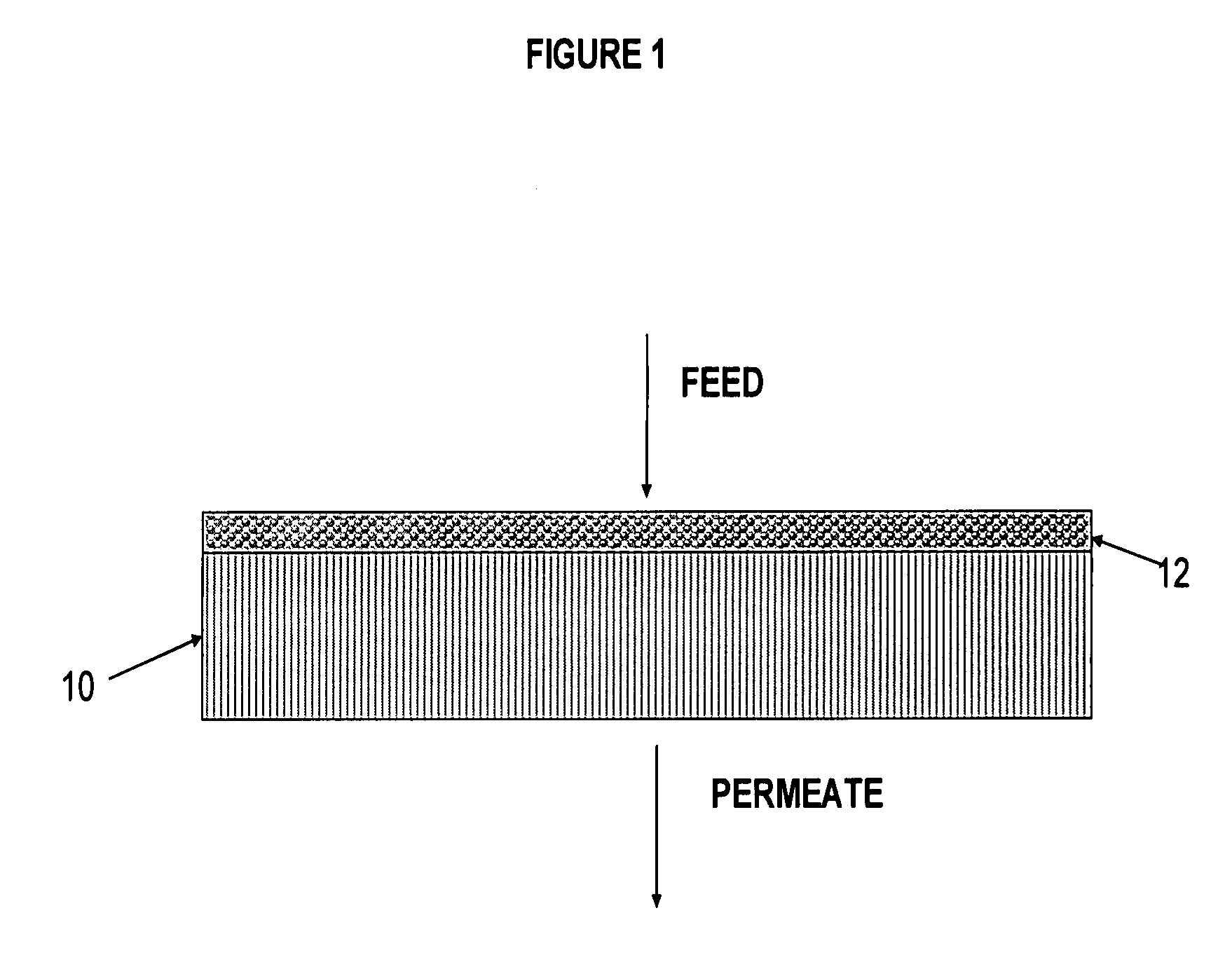

Polymer-coated inorganic membrane for separating aromatic and aliphatic compounds

InactiveUS20080035557A1Promotes uniform depositionMaximizing permeationMembranesDialysisSilicon dioxideMembrane composition

A membrane composition comprising an inorganic substrate which has a coating of an associating polymer. The membrane composition includes an inorganic substrate selected from the group consisting of a porous silica hollow tube, an alumina hollow tube and a ceramic monolith.

Owner:PARTRIDGE RANDALL D +3

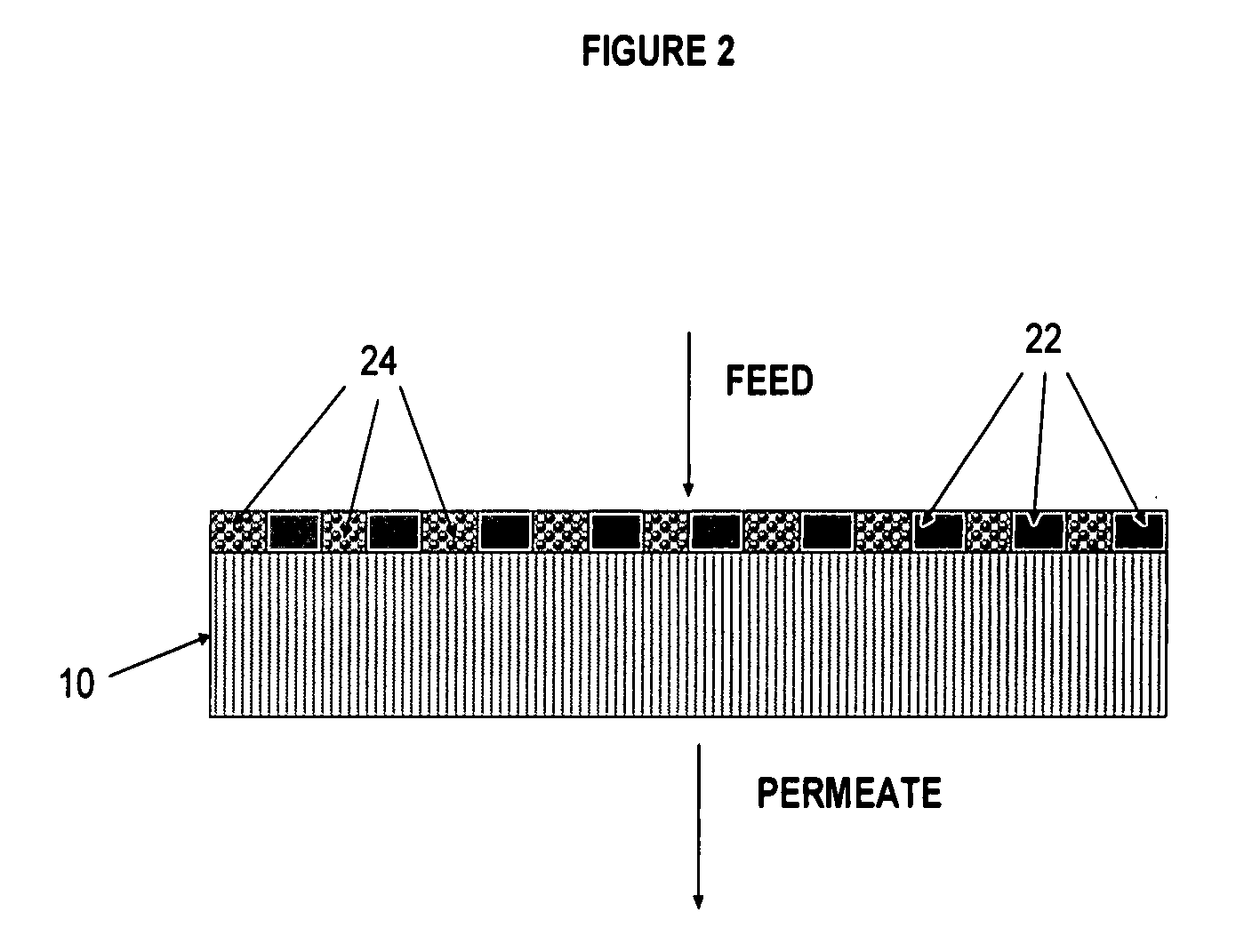

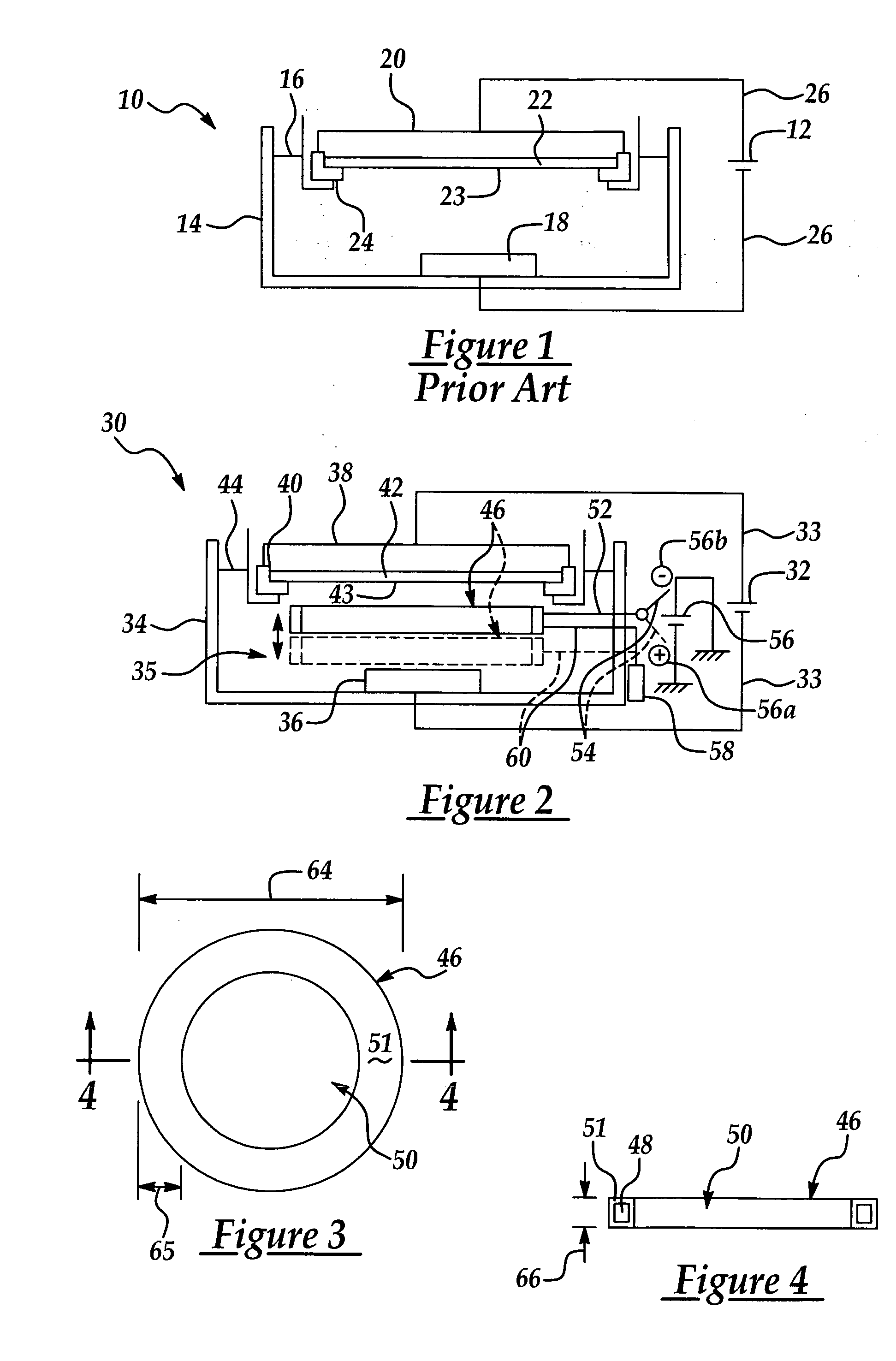

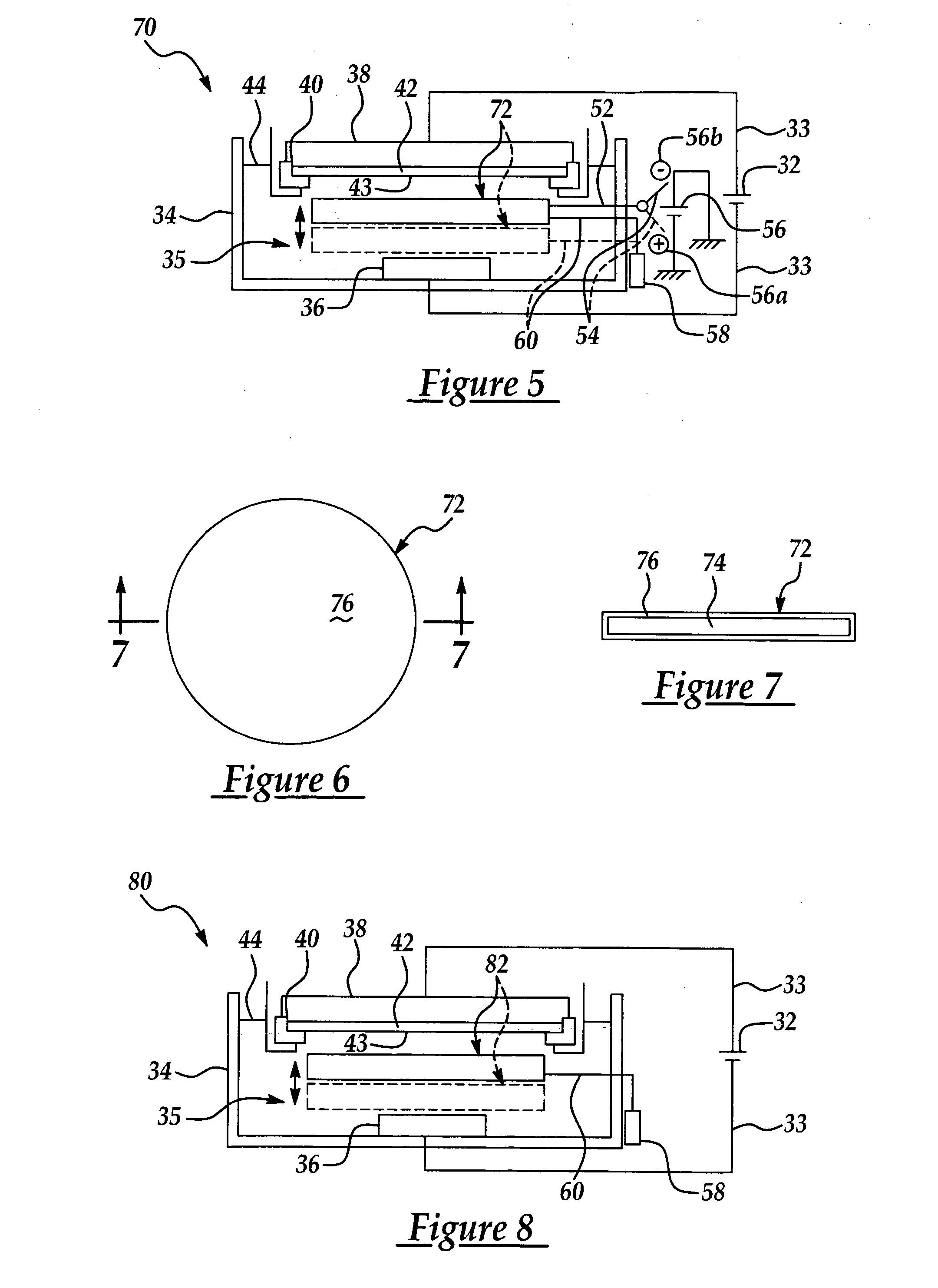

Electroplating apparatus

InactiveUS20050189228A1Enhanced thickness uniformityReduce quantityCellsAnodisationEdge regionCurrent source

A electroplating apparatus which is suitable for depositing a metal layer of substantially uniform thickness across the center and edge regions of a semiconductor wafer substrate is disclosed. The apparatus includes a reservoir for containing an electrolytic fluid. A cathode, to which is mounted a wafer, and an anode in the electrolytic fluid are connected to an electroplating current source. A shield is provided between the cathode and anode to facilitate a more uniform deposit of the metal onto the wafer across the entire surface, including the center and edge regions, of the wafer.

Owner:TAIWAN SEMICON MFG CO LTD

Lithium-ion electrochemical cell, components thereof, and methods of making and using same

ActiveUS20140170478A1Improve efficiencyProlong lifeAlkaline accumulatorsFinal product manufactureLithiumNitrogen

An electrochemical cell including at least one nitrogen-containing compound is disclosed. The at least one nitrogen-containing compound may form part of or be included in: an anode structure, a cathode structure, an electrolyte and / or a separator of the electrochemical cell. Also disclosed is a battery including the electrochemical cell.

Owner:SION POWER CORP

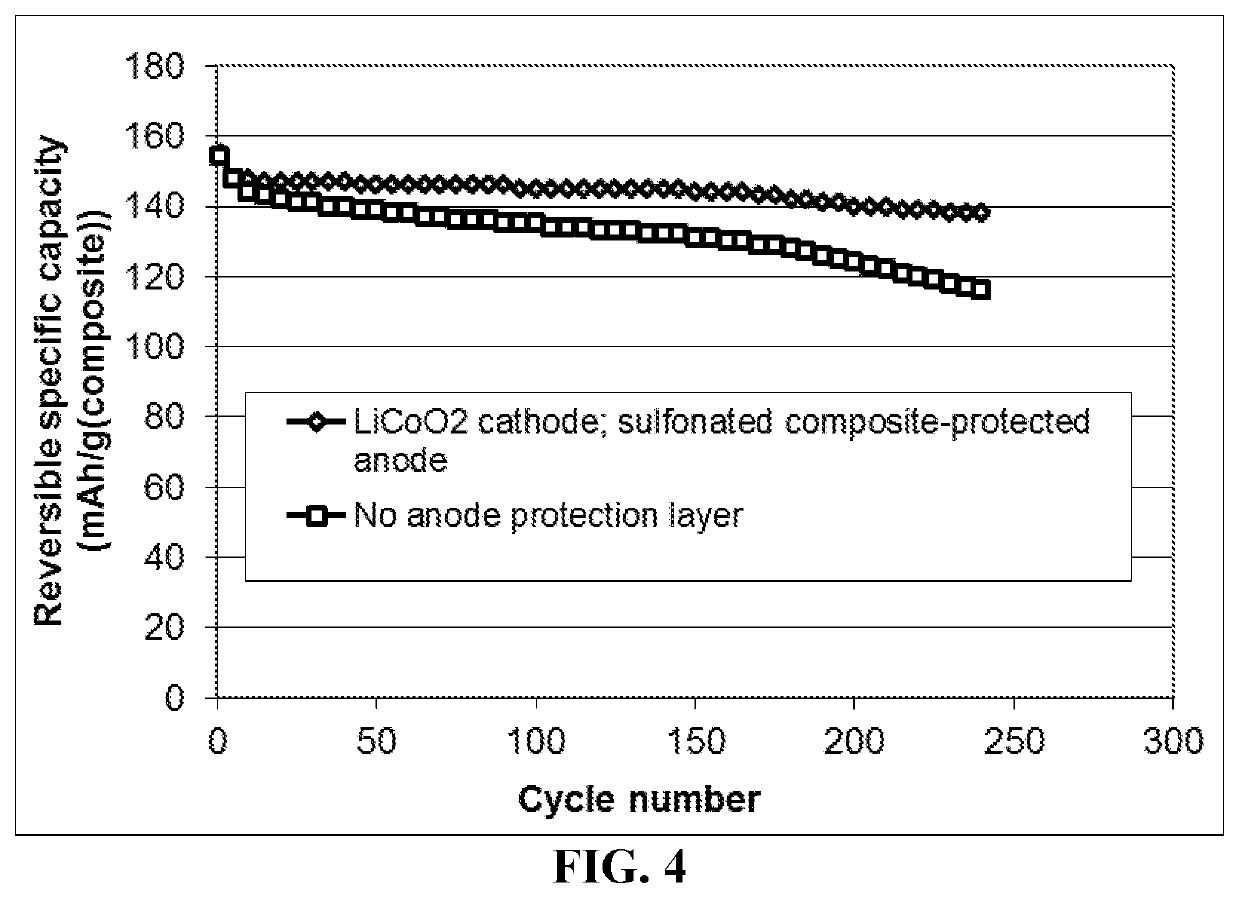

Method of extending cycle-life of a lithium-sulfur battery

ActiveUS20200028179A1Reduces and eliminate shuttling effectReduce and eliminate effectCell electrodesElectrolytesElectrically conductiveElectrical battery

The invention provides a method of improving the cycle-life of a rechargeable alkali metal-sulfur cell. The method comprises implementing an anode-protecting layer between an anode active material layer and a porous separator / electrolyte, and / or implementing a cathode-protecting layer between a cathode active material and the porous separator / electrolyte, wherein the anode-protecting layer or cathode-protecting layer comprises a conductive sulfonated elastomer composite having from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an electrochemically stable inorganic filler dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm when measured at room temperature.

Owner:GLOBAL GRAPHENE GRP INC

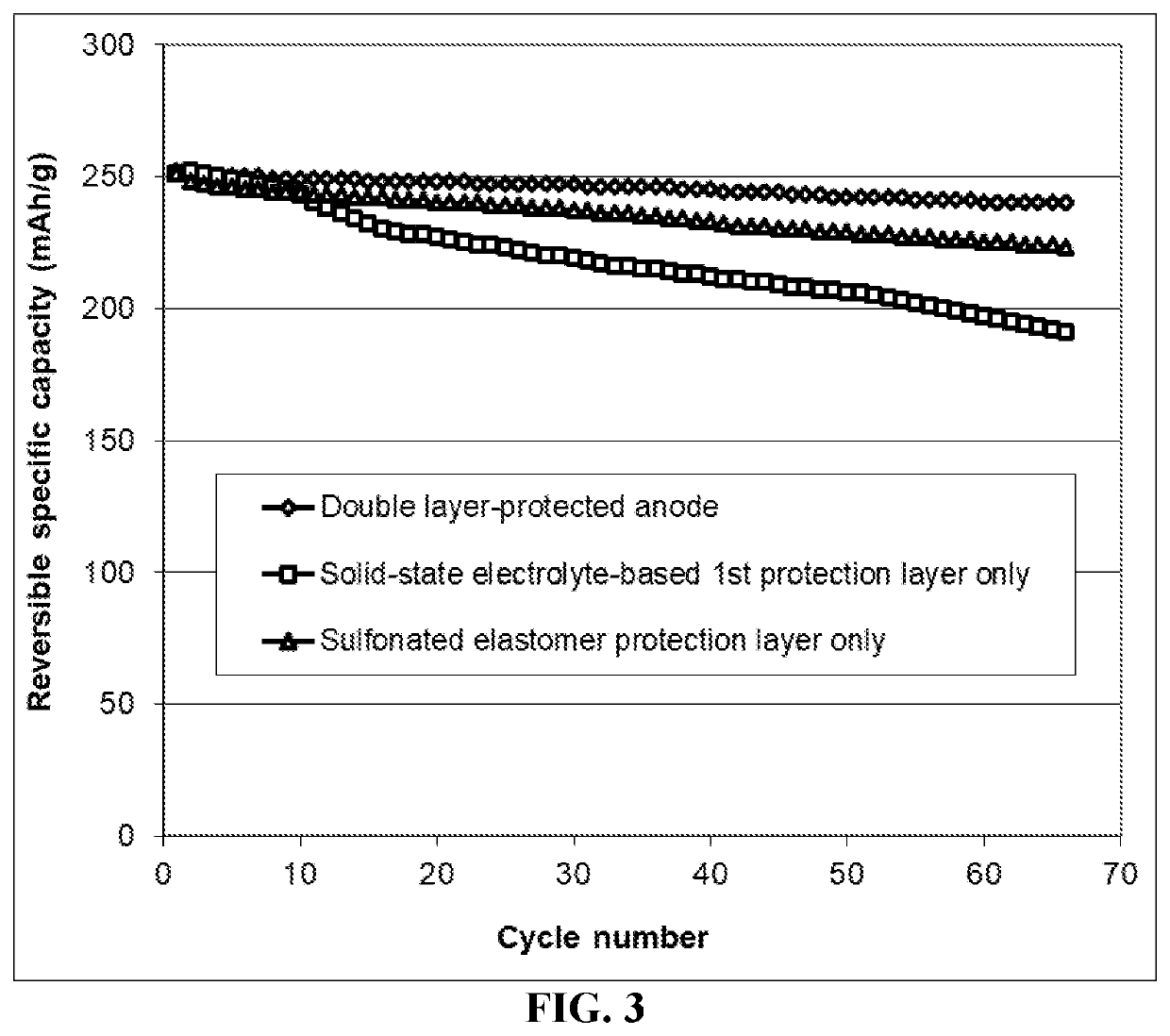

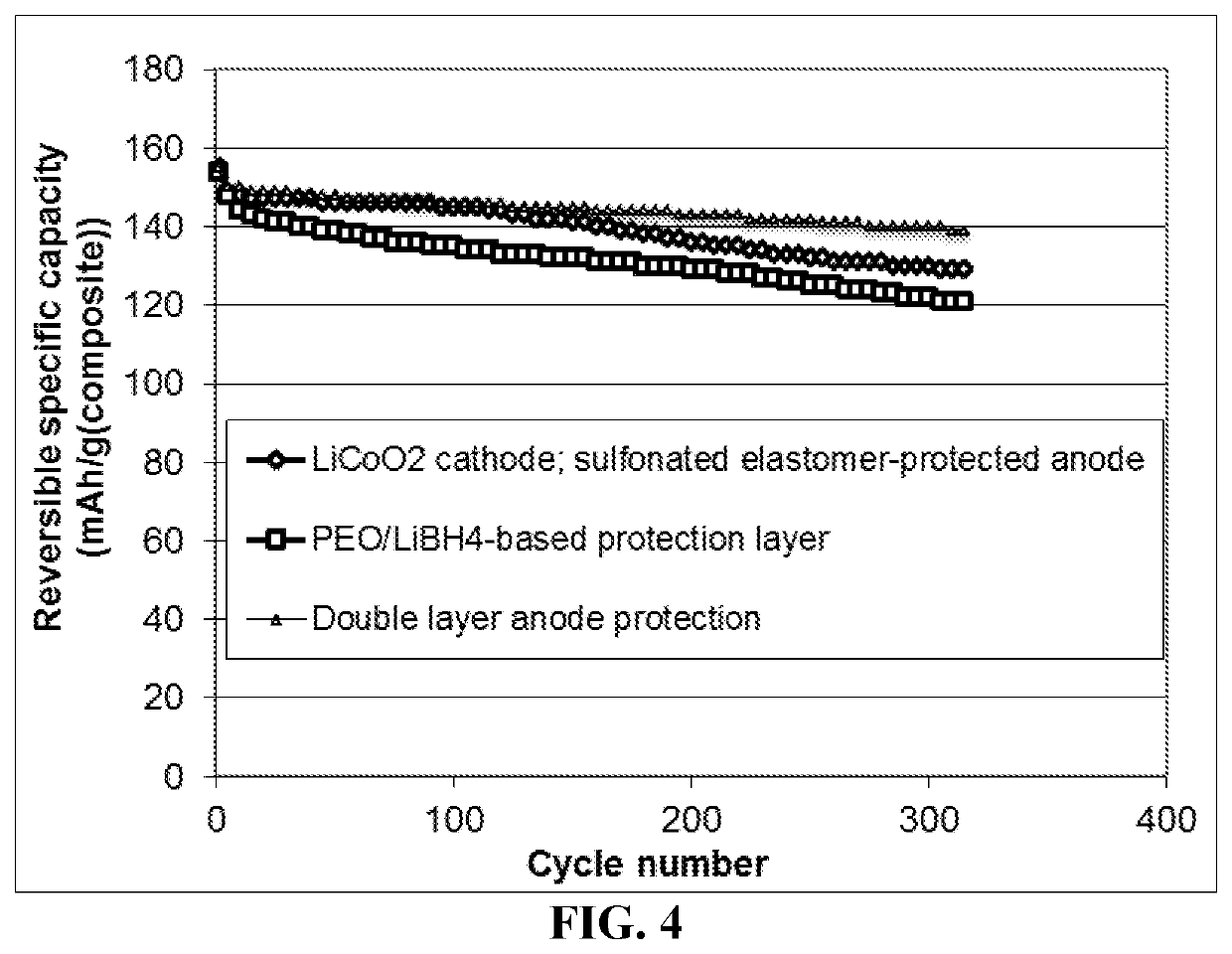

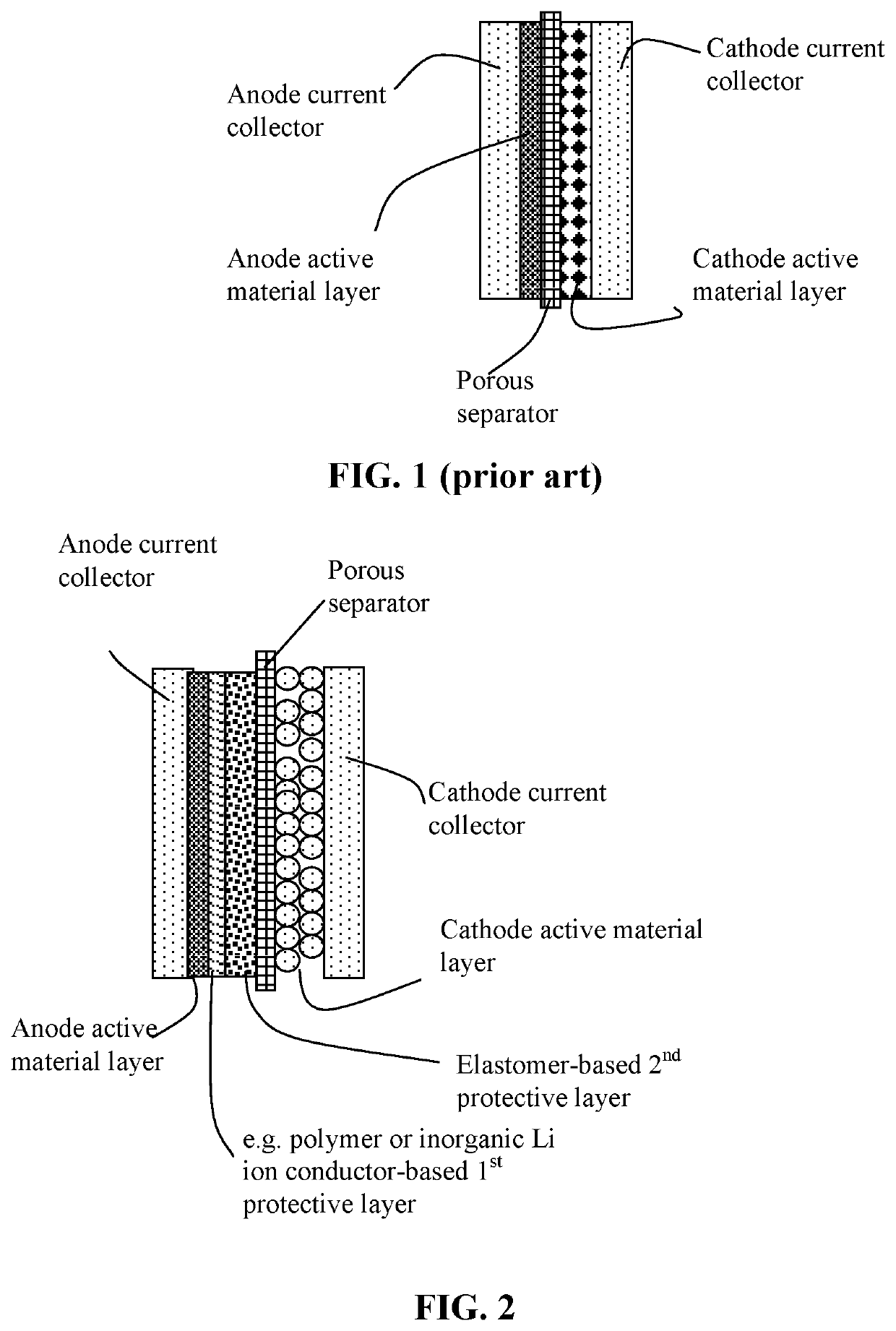

Method of protecting the lithium anode layer in a lithium metal secondary battery

PendingUS20190393482A1Reduce eliminatePromotes uniform depositionSolid electrolytesElectrode manufacturing processesLithium metalPhysical chemistry

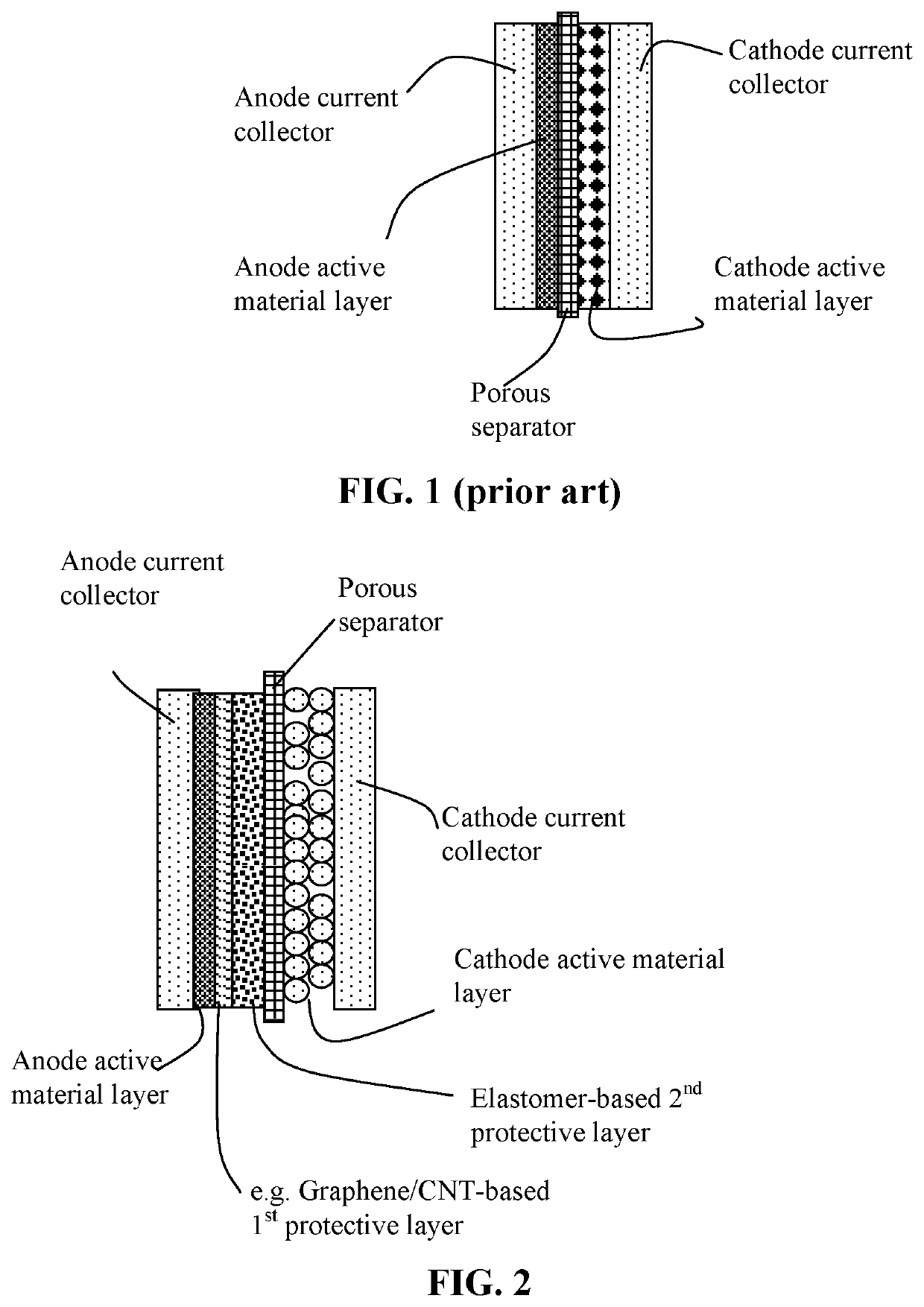

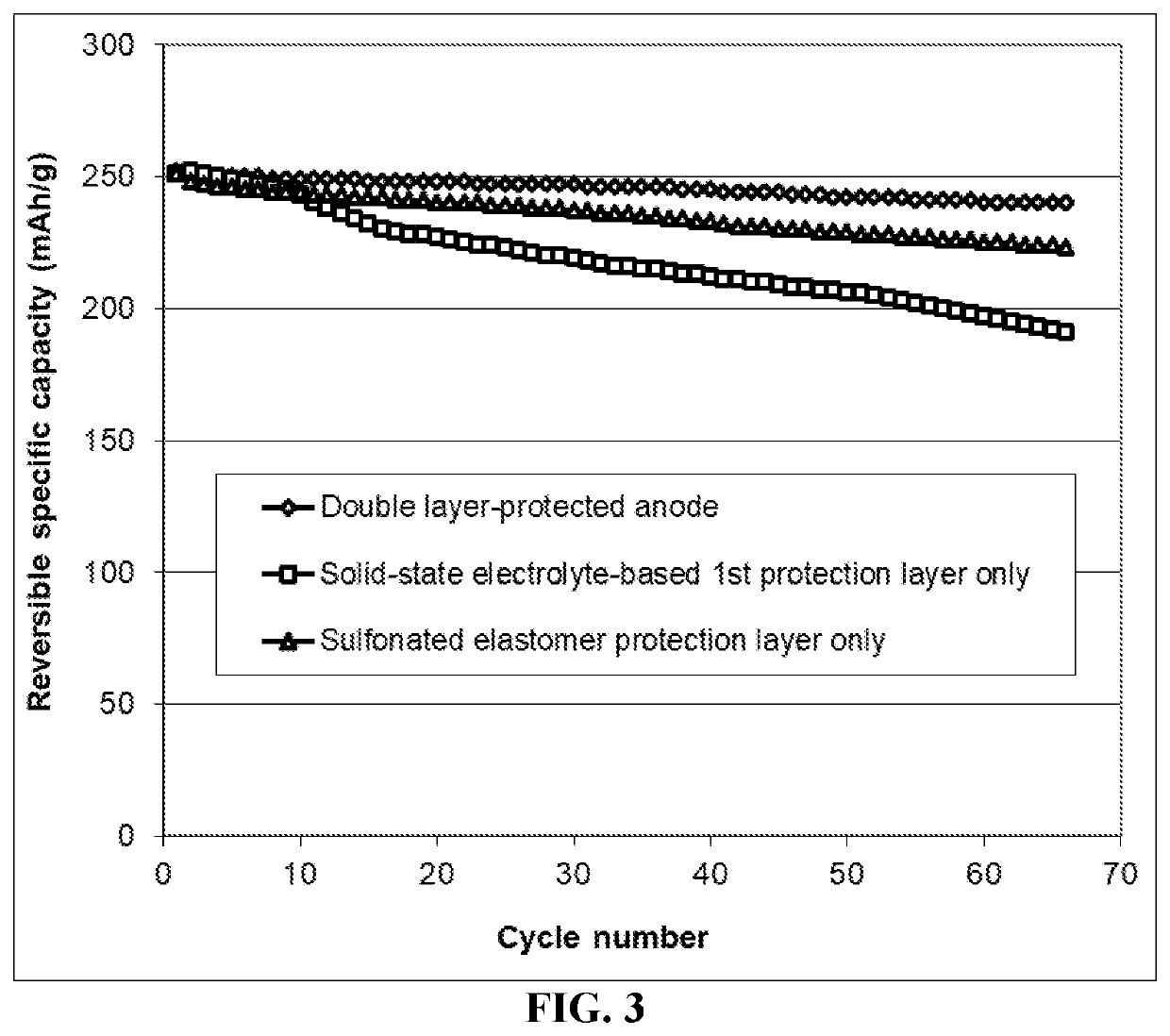

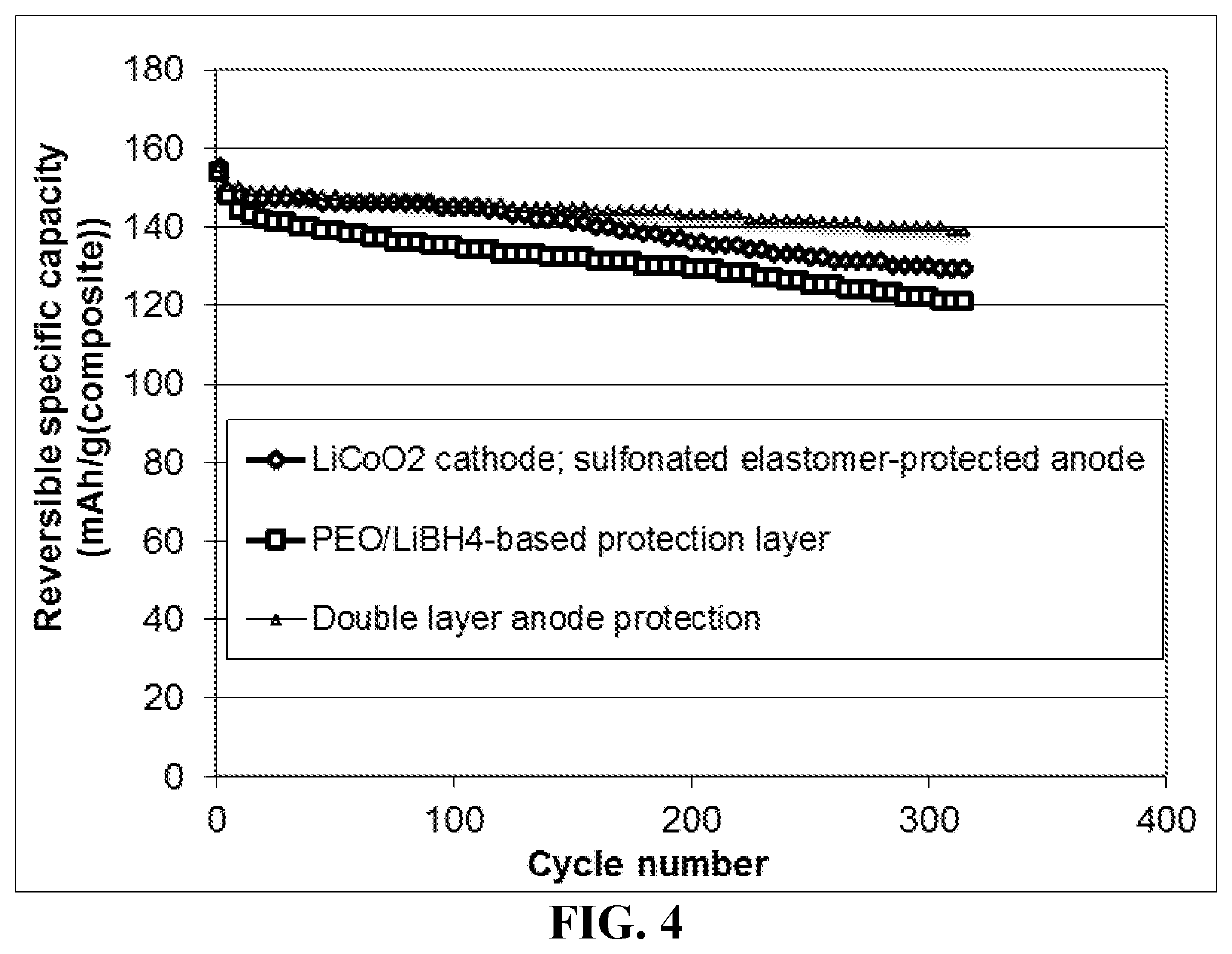

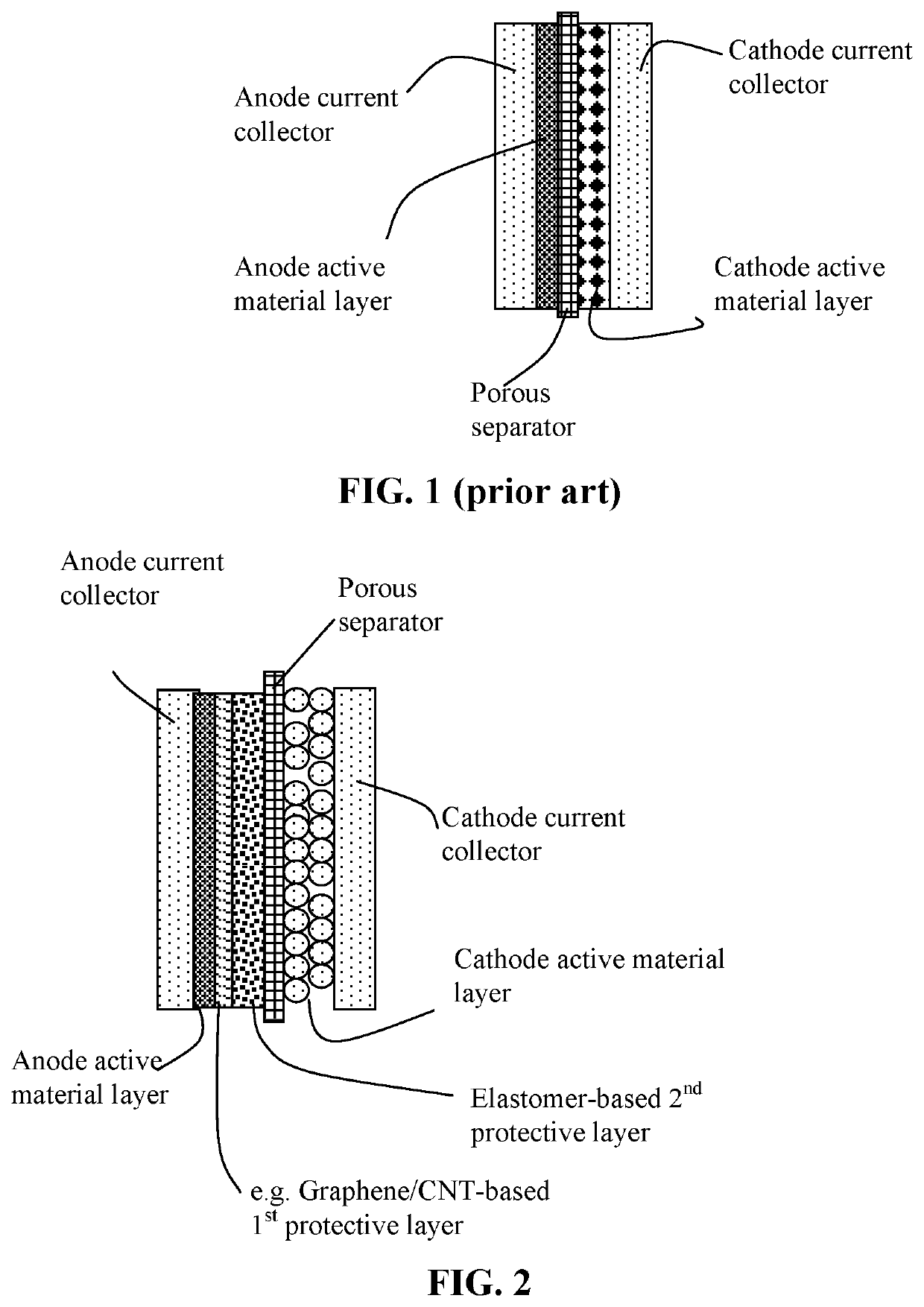

The invention provides a method of improving the anode stability and cycle-life of a lithium metal secondary battery. The method comprises implementing two anode-protecting layers between an anode active material layer and an electrolyte or electrolyte / separator assembly. These two layers comprise (a) a first anode-protecting layer having a thickness from 1 nm to 100 μm (preferably <1 μm and more preferably <100 nm) and comprising a lithium ion-conducting material having a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm; and (b) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% (preferably >10% more preferably >100%) and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

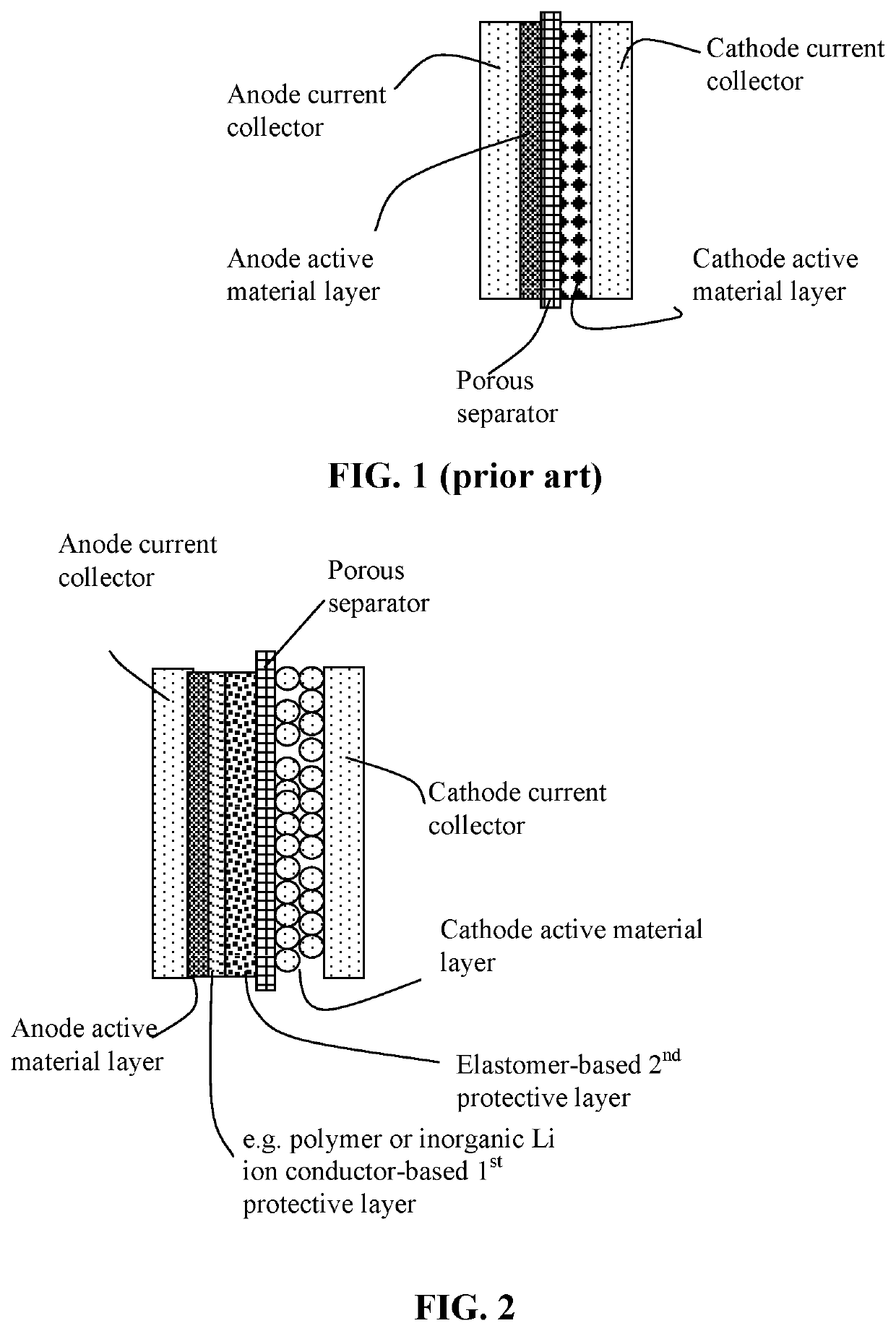

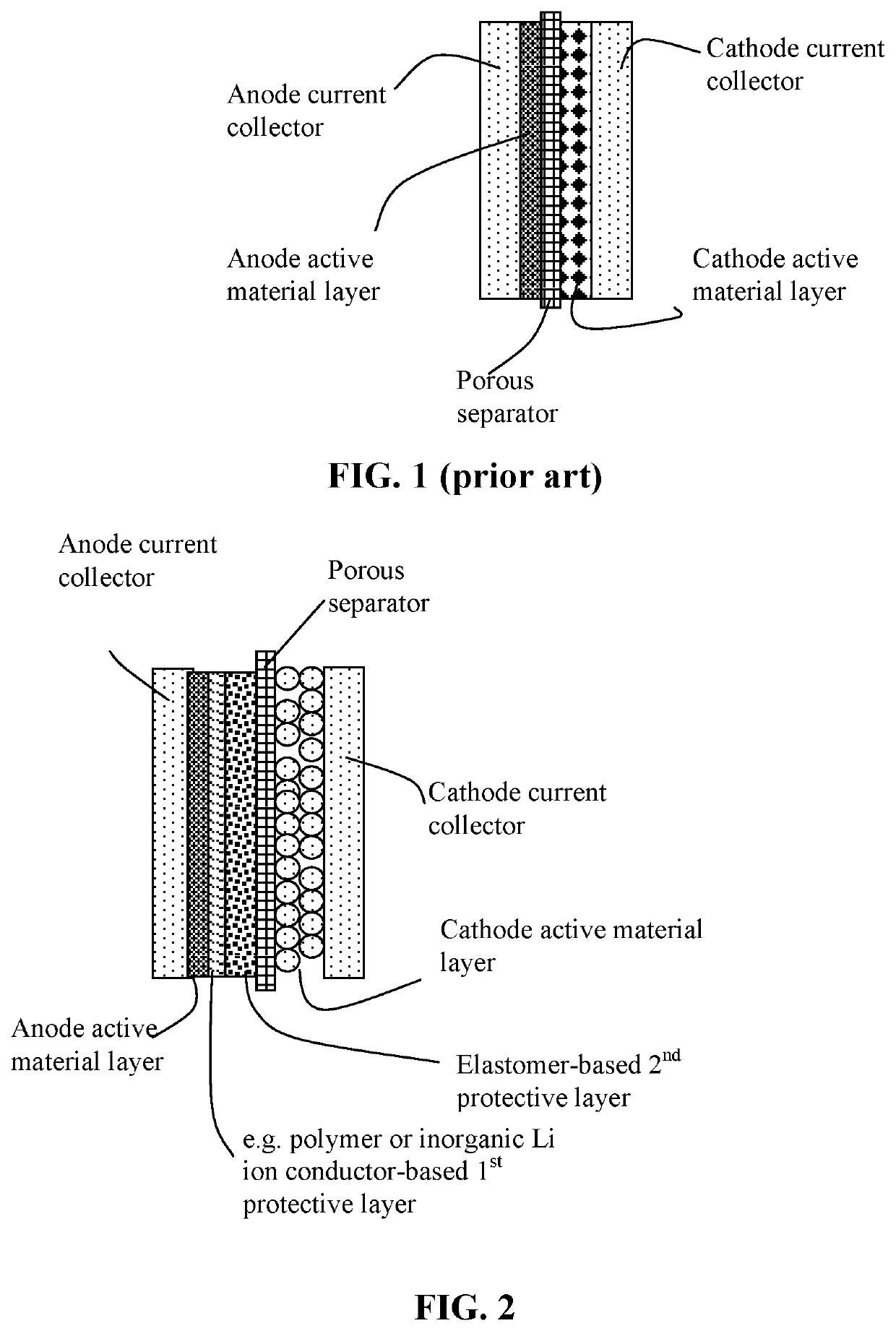

Lithium metal secondary battery containing a protected lithium anode

ActiveUS20190393487A1Reduce thicknessImprove lithium ion conductivityCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrical batteryLithium metal

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; (b) a first anode-protecting layer having a thickness from 1 nm to 100 μm (preferably <1 μm and more preferably <100 nm) and comprising a lithium ion-conducting material having a lithium ion conductivity from 108 S / cm to 5×10−2 S / cm; and (c) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 108 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

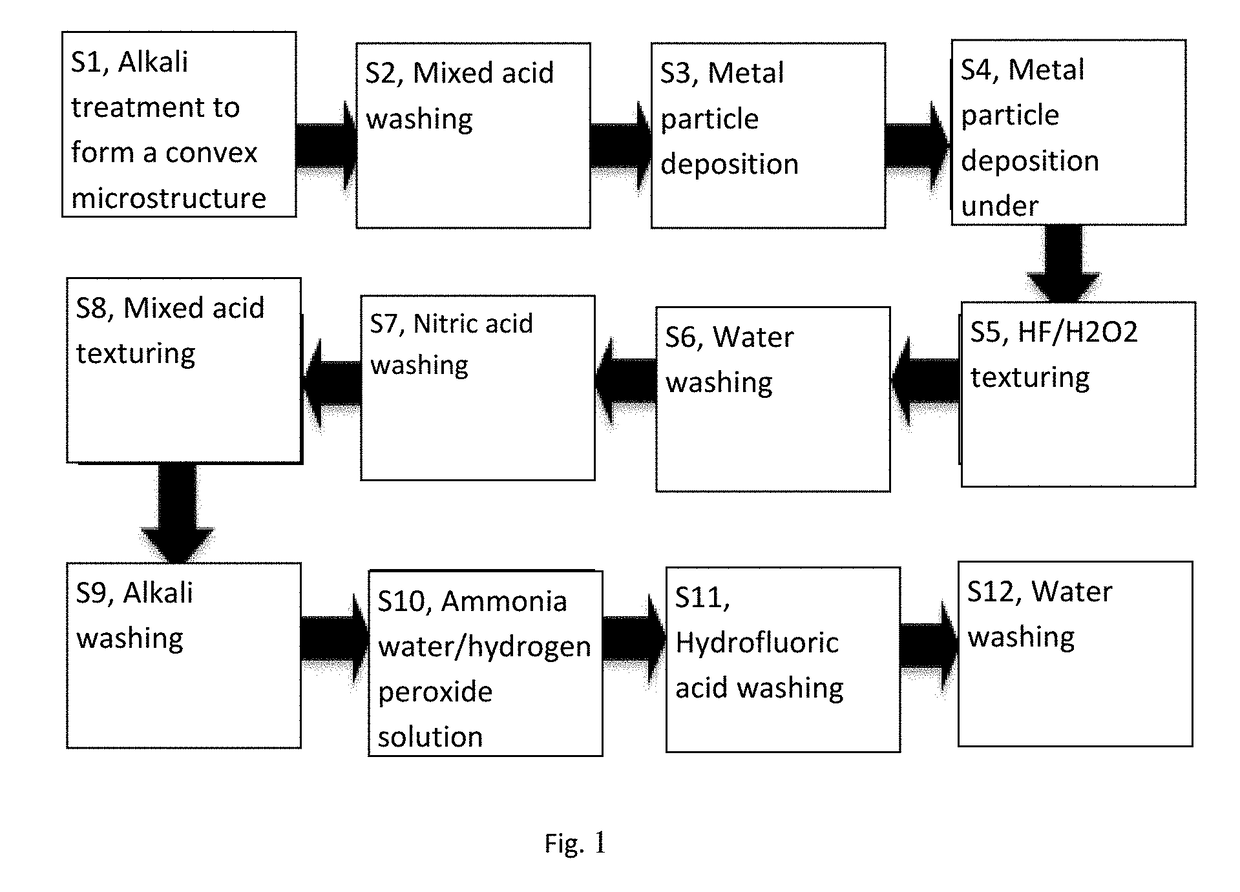

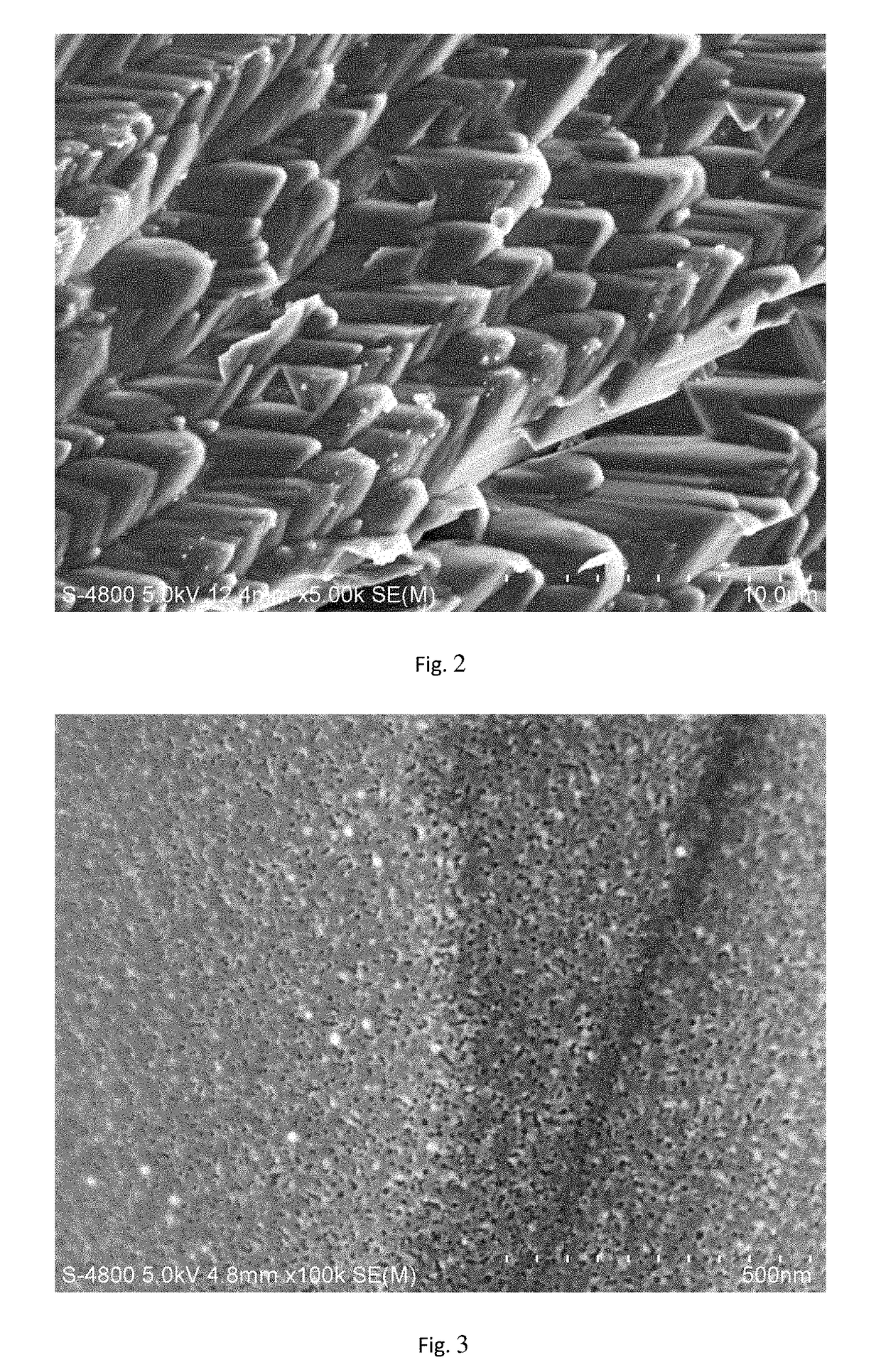

Texturing Method for Diamond Wire Cut Polycrystalline Silicon Slice

ActiveUS20190067496A1Improve conversion efficiencyLight structurePolycrystalline material growthAfter-treatment detailsHydrofluoric acidInorganic ions

It discloses a texturing method for a diamond wire cut polycrystalline silicon slice, including the following steps: firstly, immersing the diamond wire cut polycrystalline silicon slice into a mixed aqueous solution of an alkali solution and an alkali reaction control agent, removing a damaged layer on a surface of the silicon slice, and then immersing the silicon slice into a hydrofluoric acid solution containing inorganic ions and organic molecules for reaction; secondly, pretreating the polycrystalline silicon surface by a mixed solution of hydrofluoric acid and hydrogen peroxide, adding a pore-forming regulator at the same time, and finally texturing the surface of the silicon slice by a mixed acid solution of hydrofluoric acid and nitric acid.

Owner:NANJING UNIV OF TECH

Method of improving anode stability in a lithium metal secondary battery

PendingUS20190393486A1Decrease exchange current densityPromotes uniform depositionSolid electrolytesElectrode manufacturing processesElastomerFiber

The invention provides a method of improving the anode stability and cycle-life of a lithium metal secondary battery. The method comprises implementing two anode-protecting layers between an anode active material layer and an electrolyte / separator assembly. These two layers comprise (a) a first anode-protecting layer having a thickness from 1 nm to 100 μm, a specific surface area greater than 50 m2 / g and comprising a thin layer of electron-conducting material selected from graphene sheets, carbon nanotubes, carbon nanofibers, carbon or graphite fibers, expanded graphite flakes, metal nanowires, conductive polymer fibers, or a combination thereof; and (b) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% (preferably >10%) and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

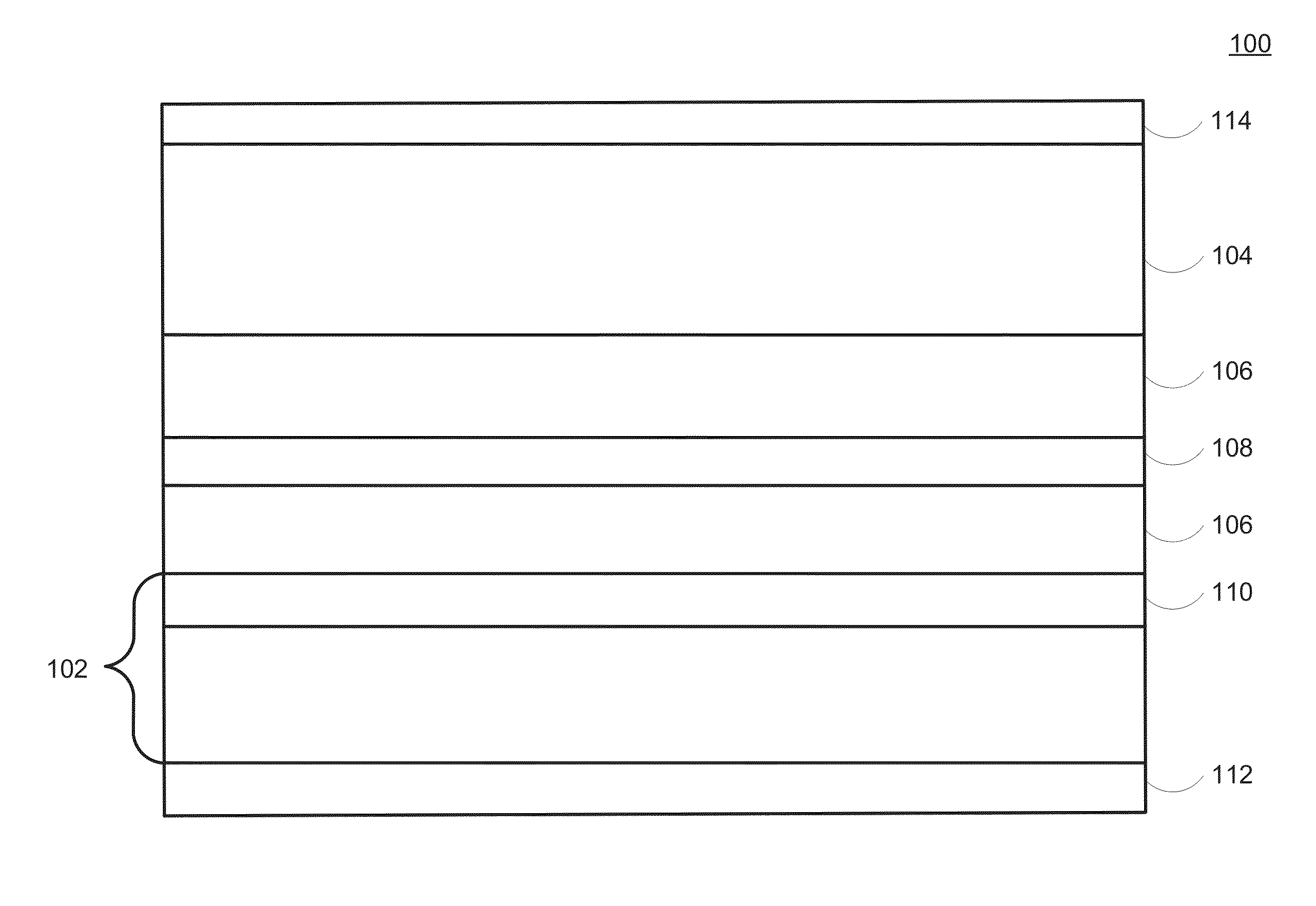

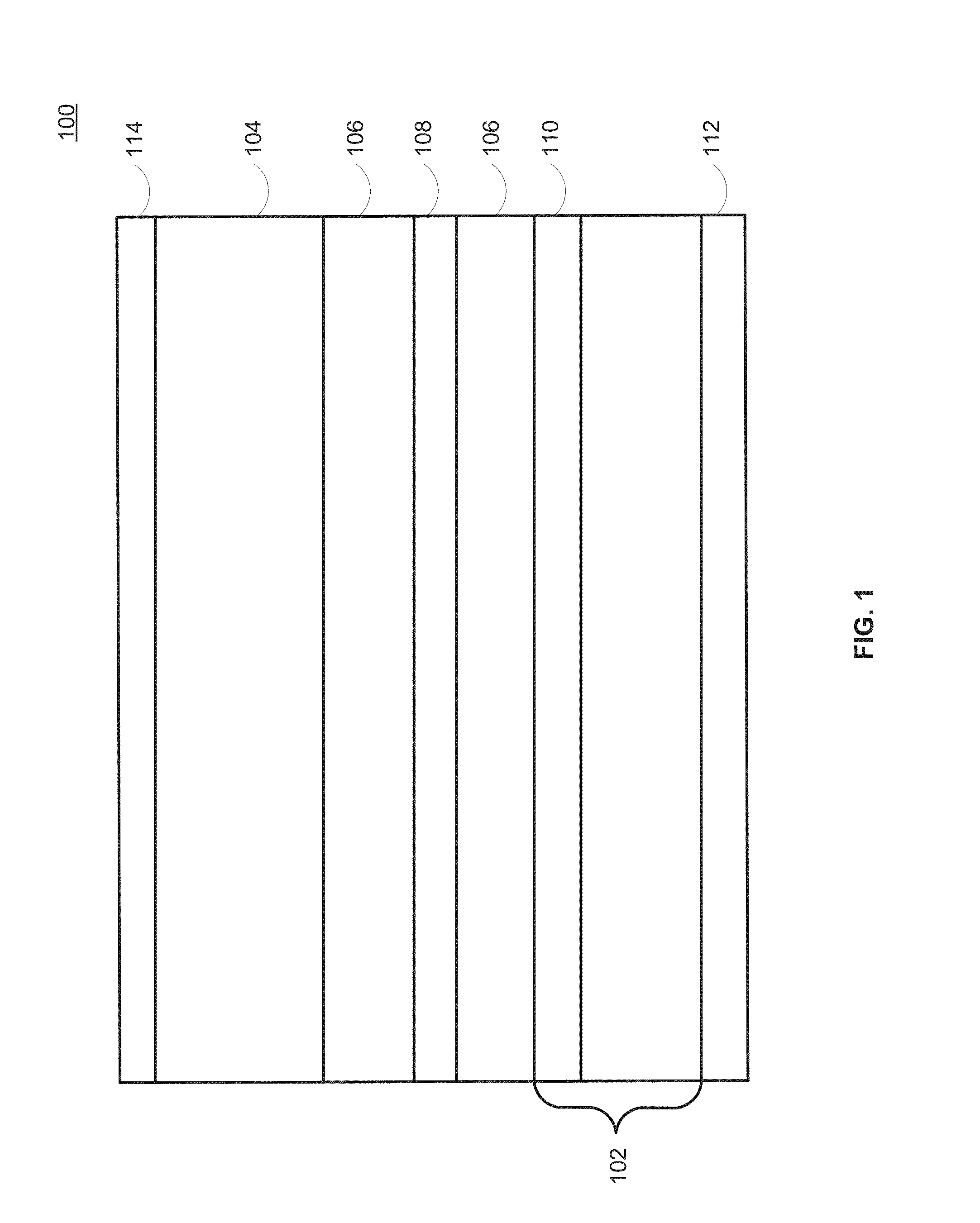

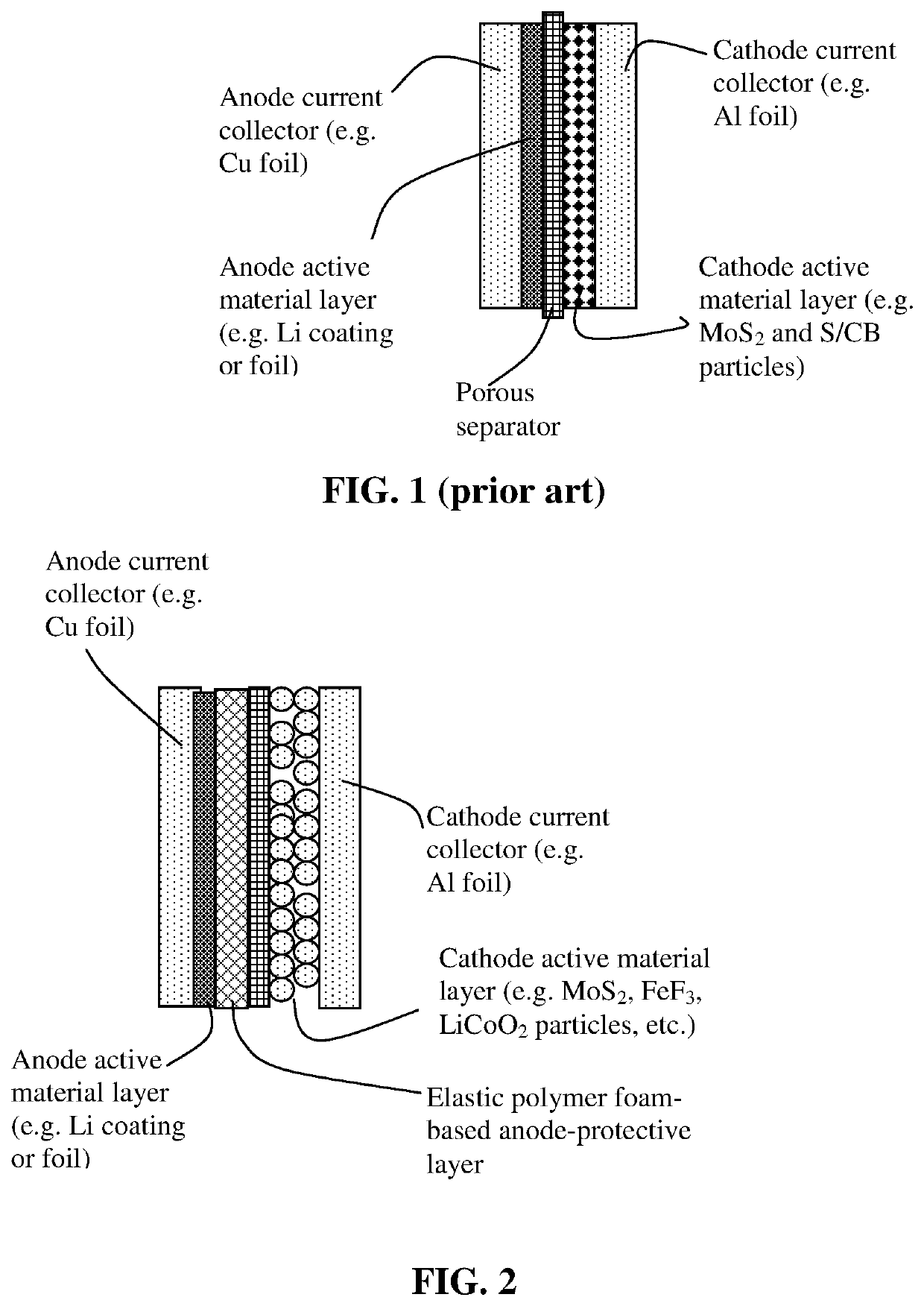

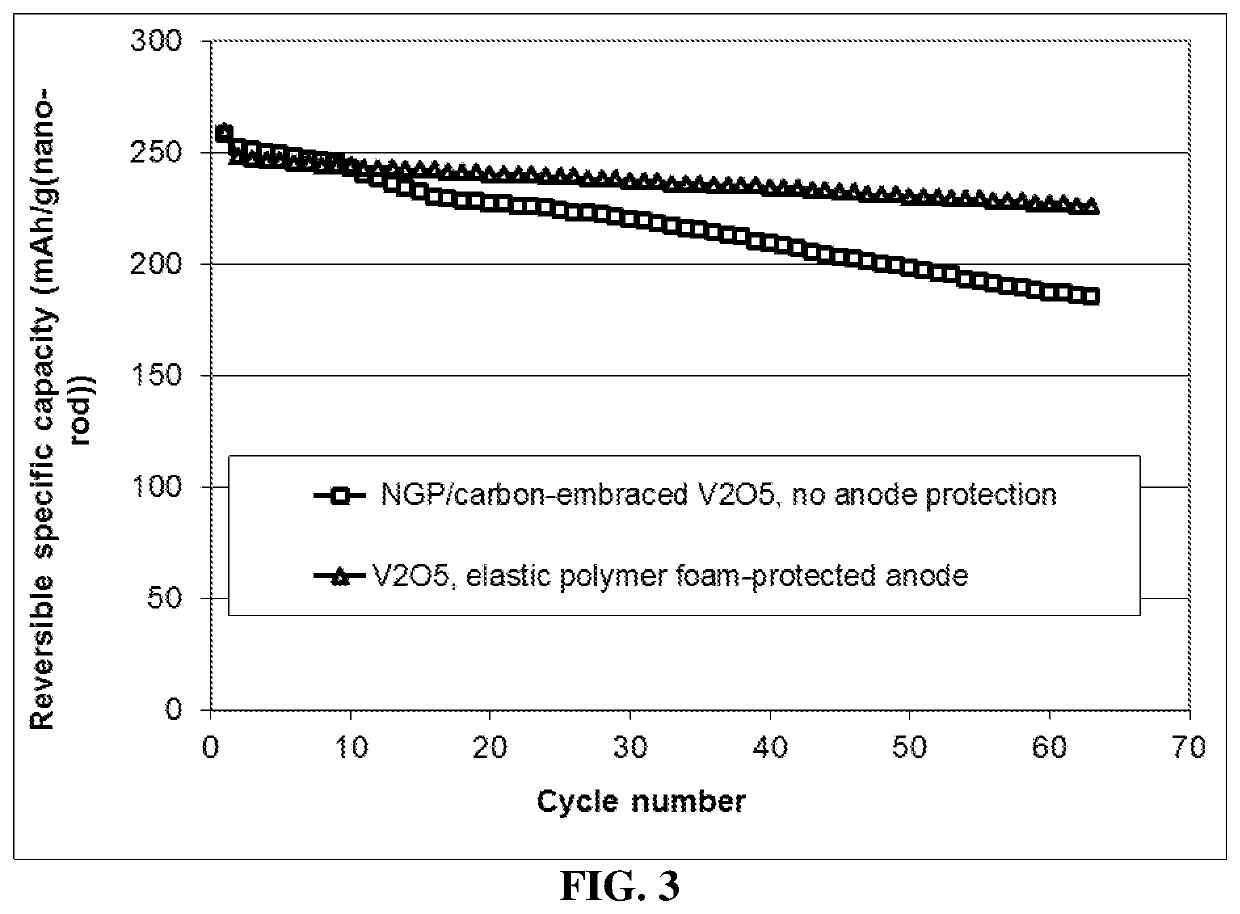

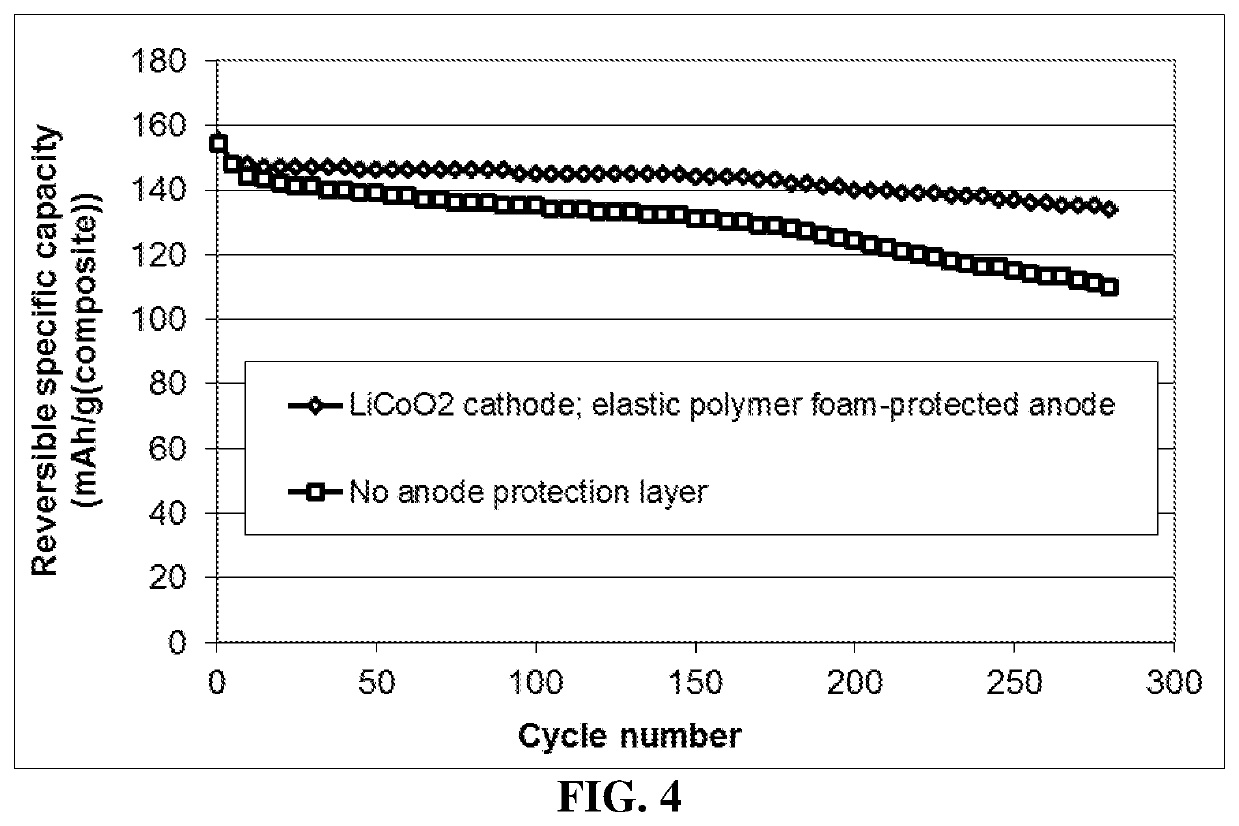

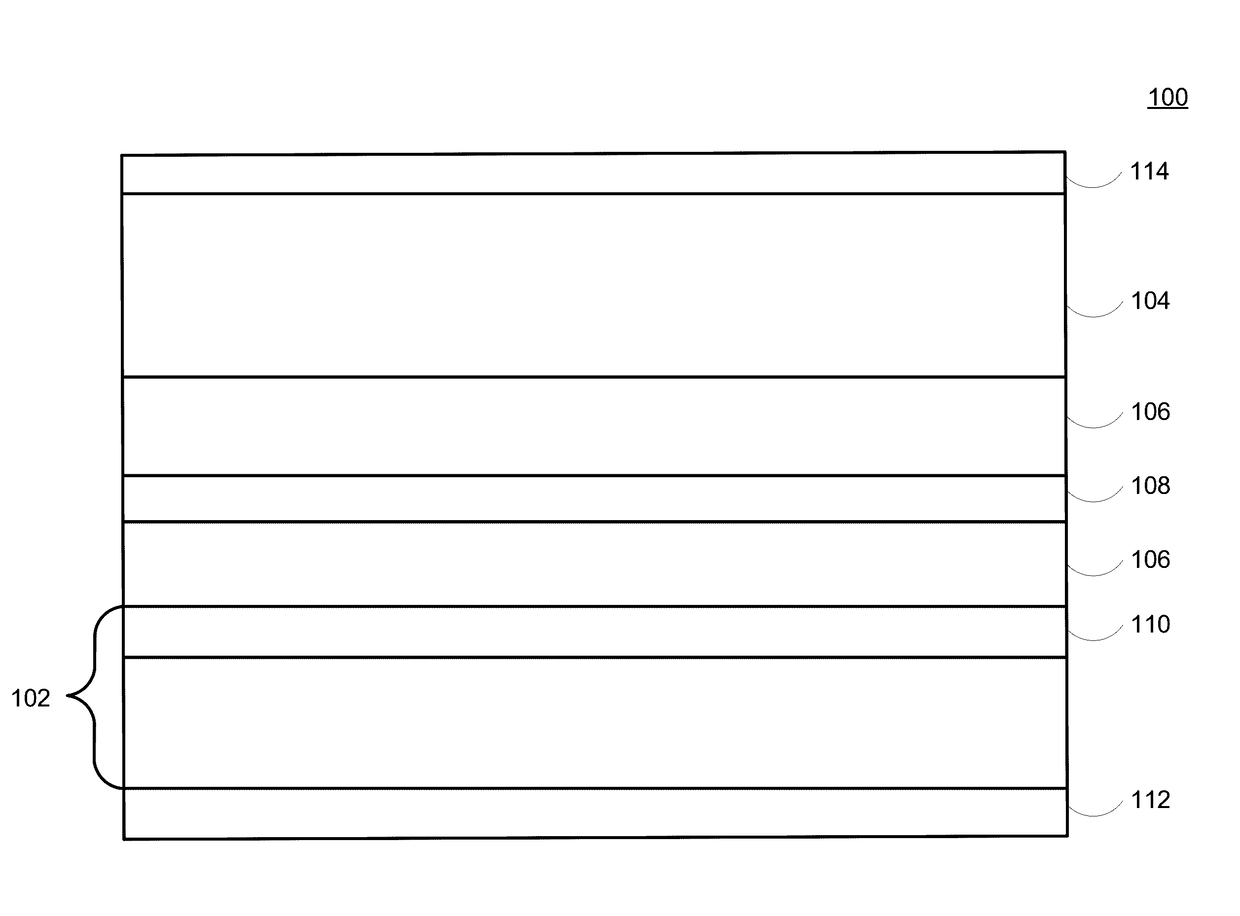

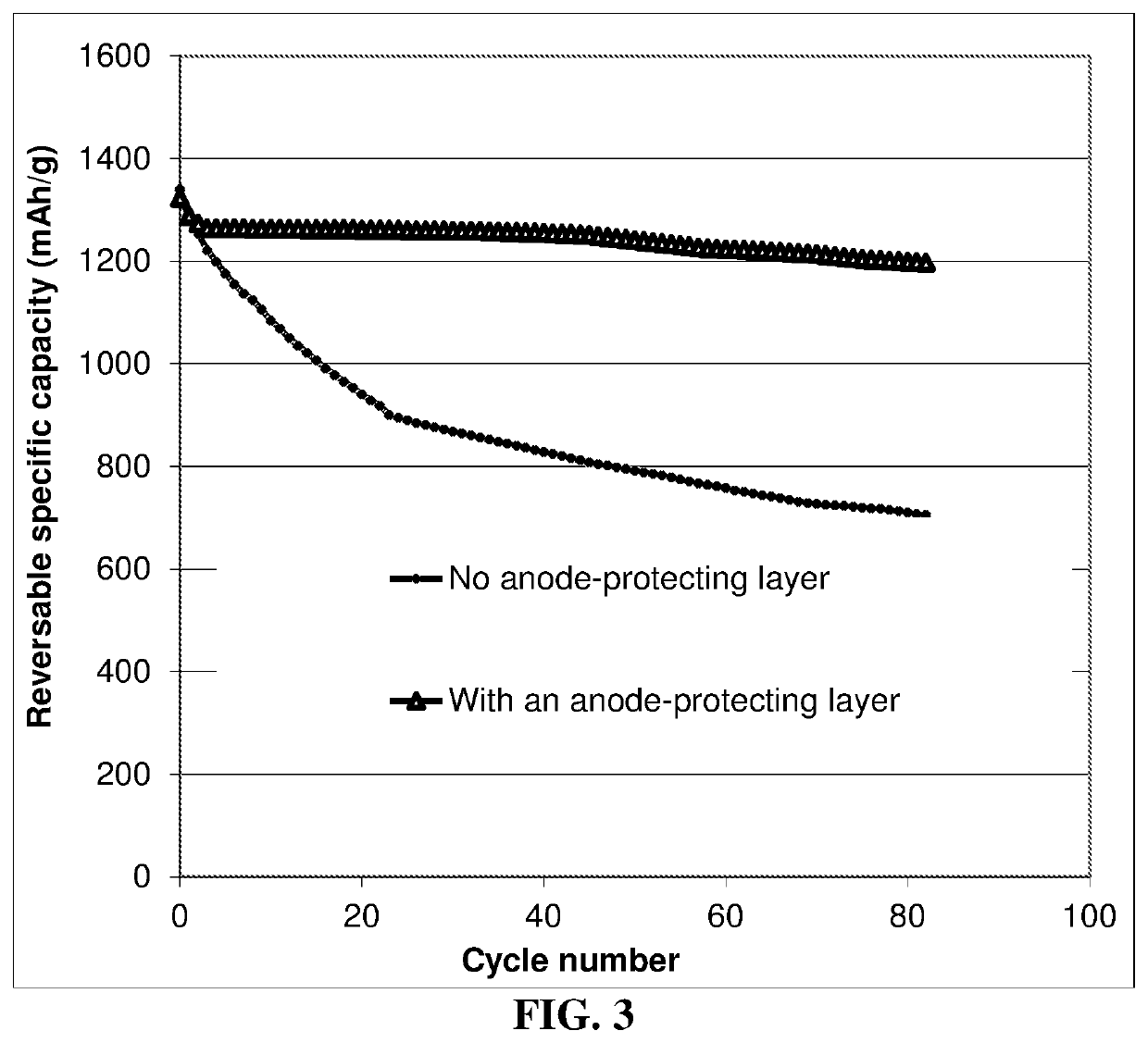

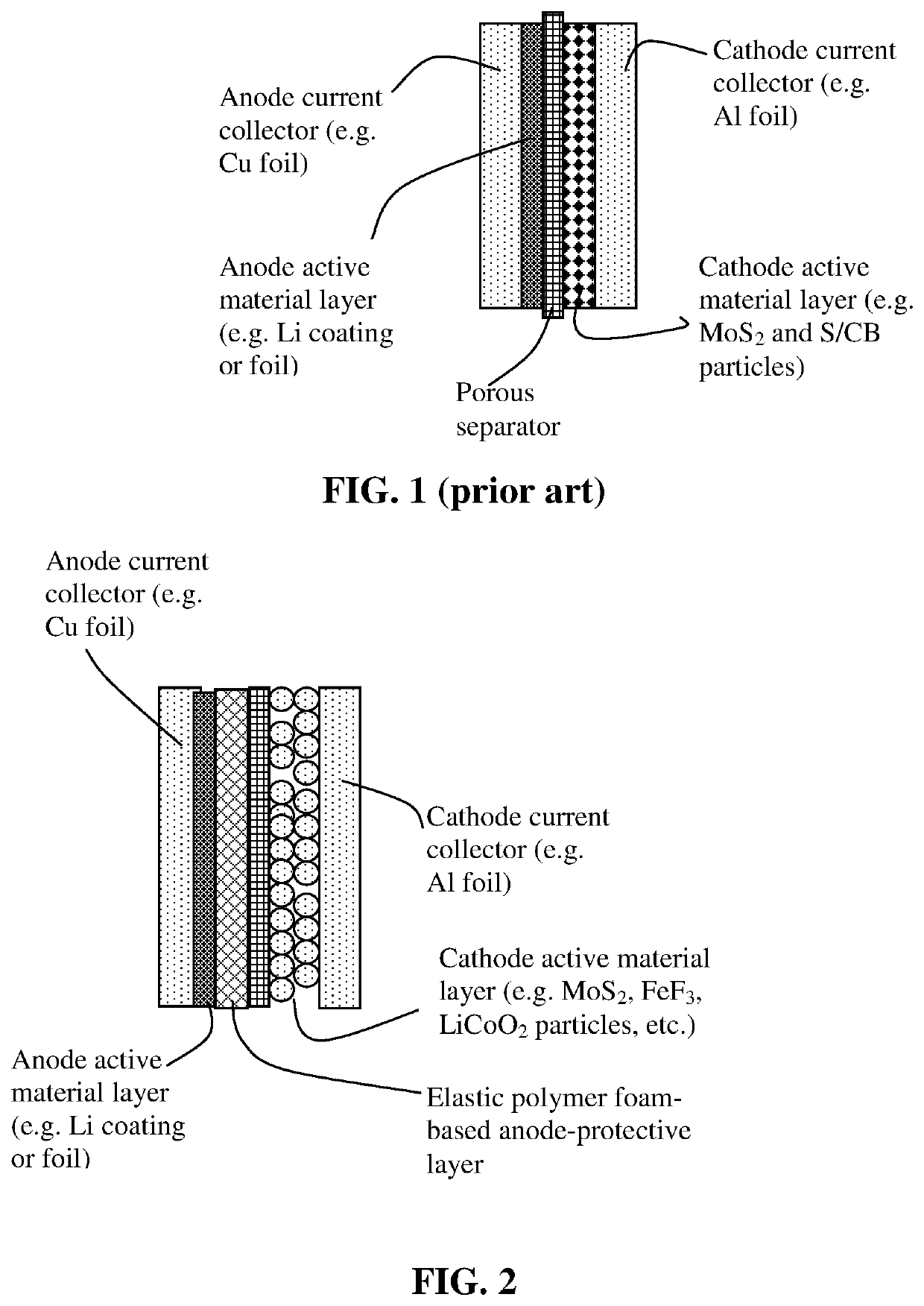

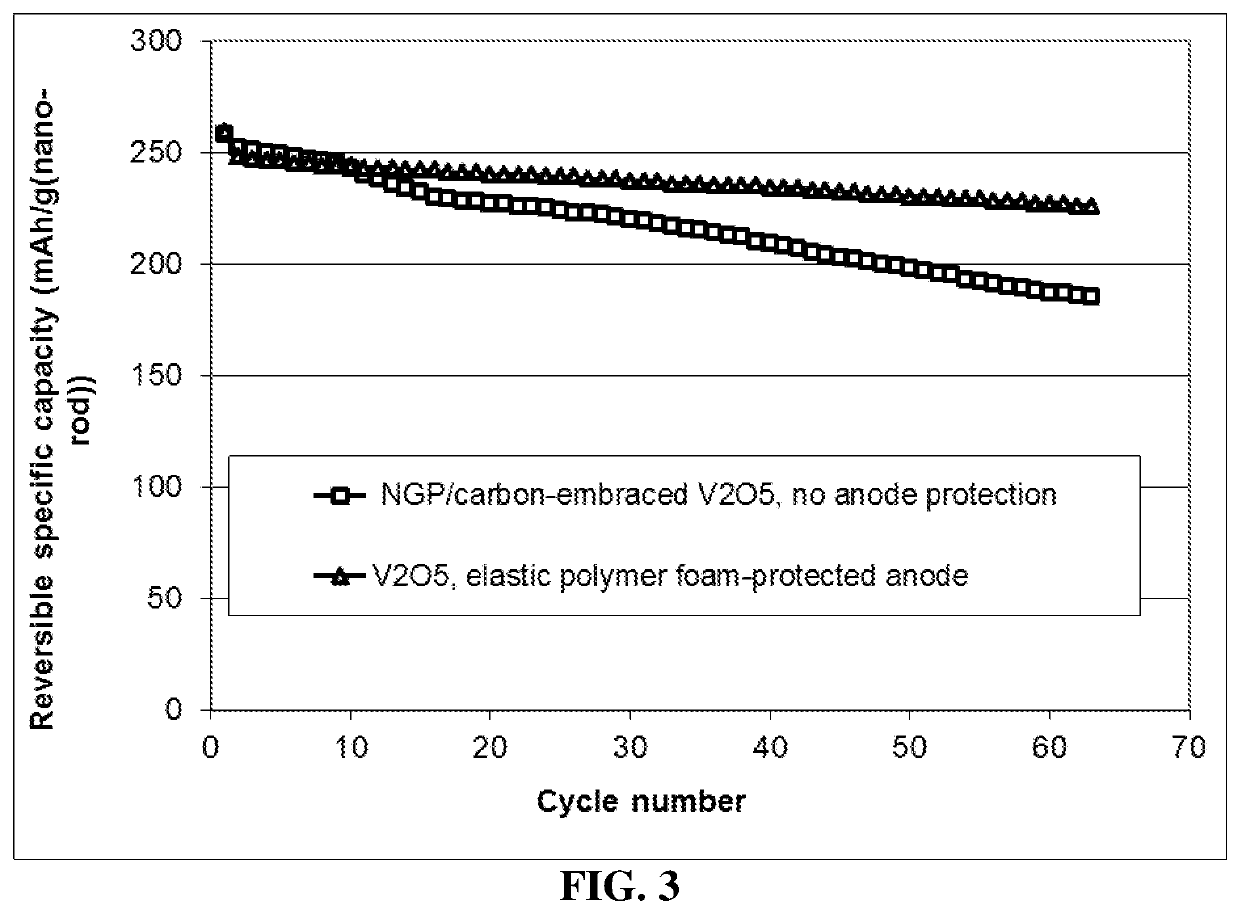

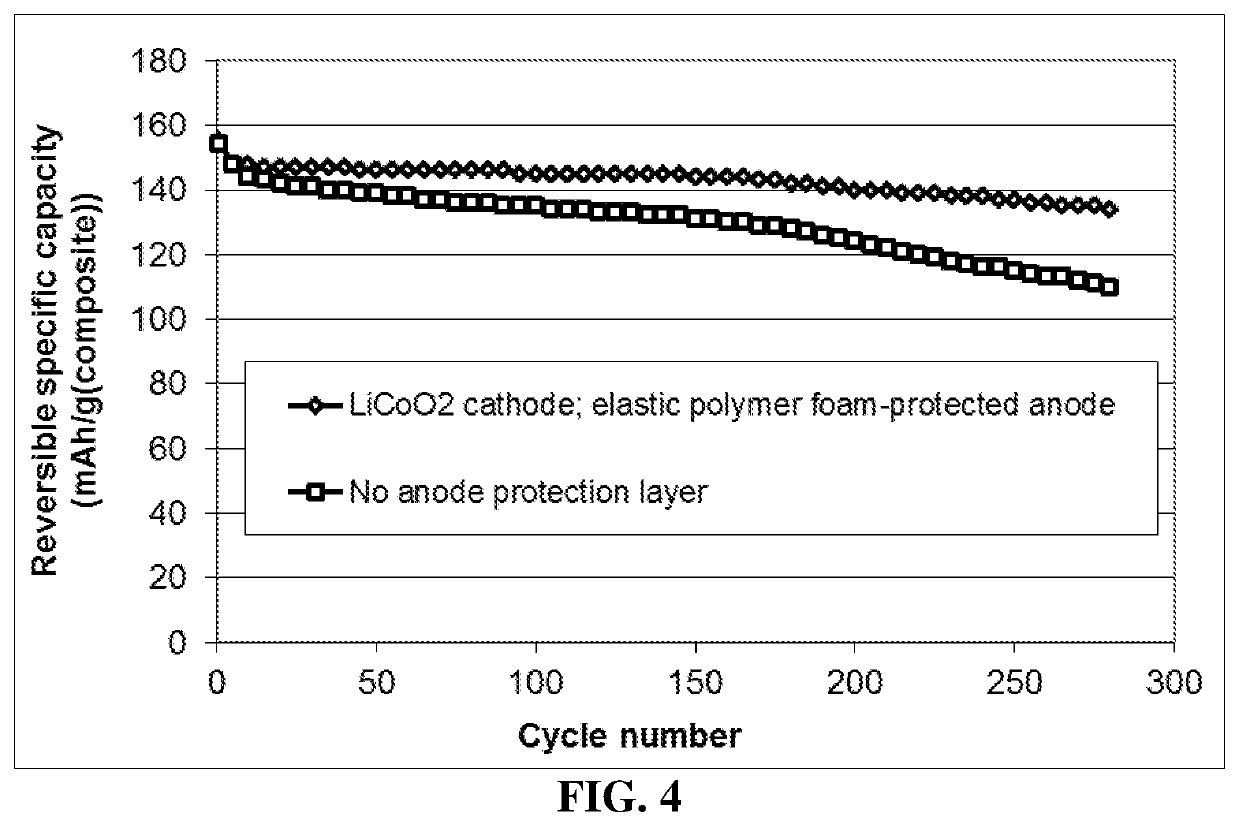

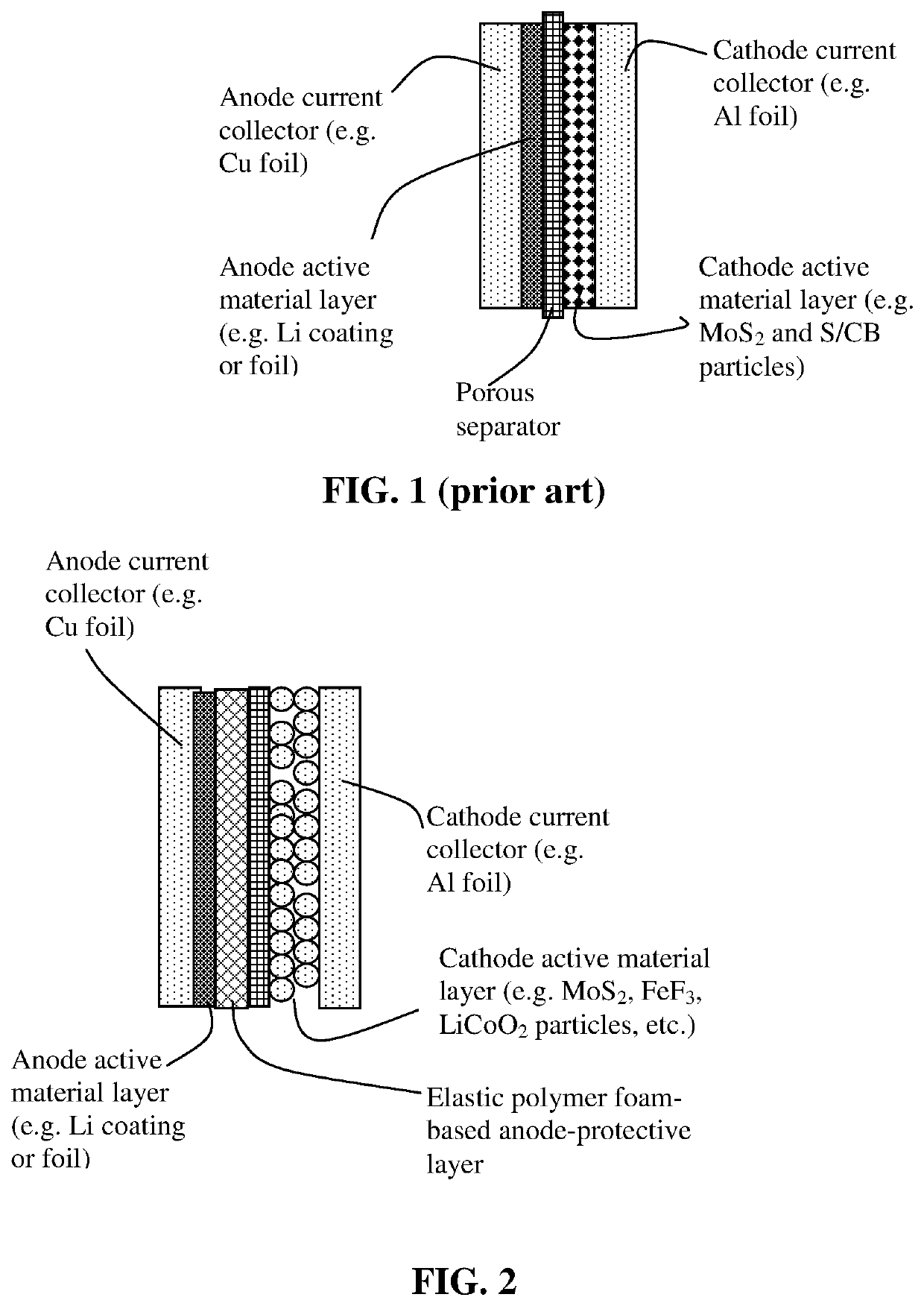

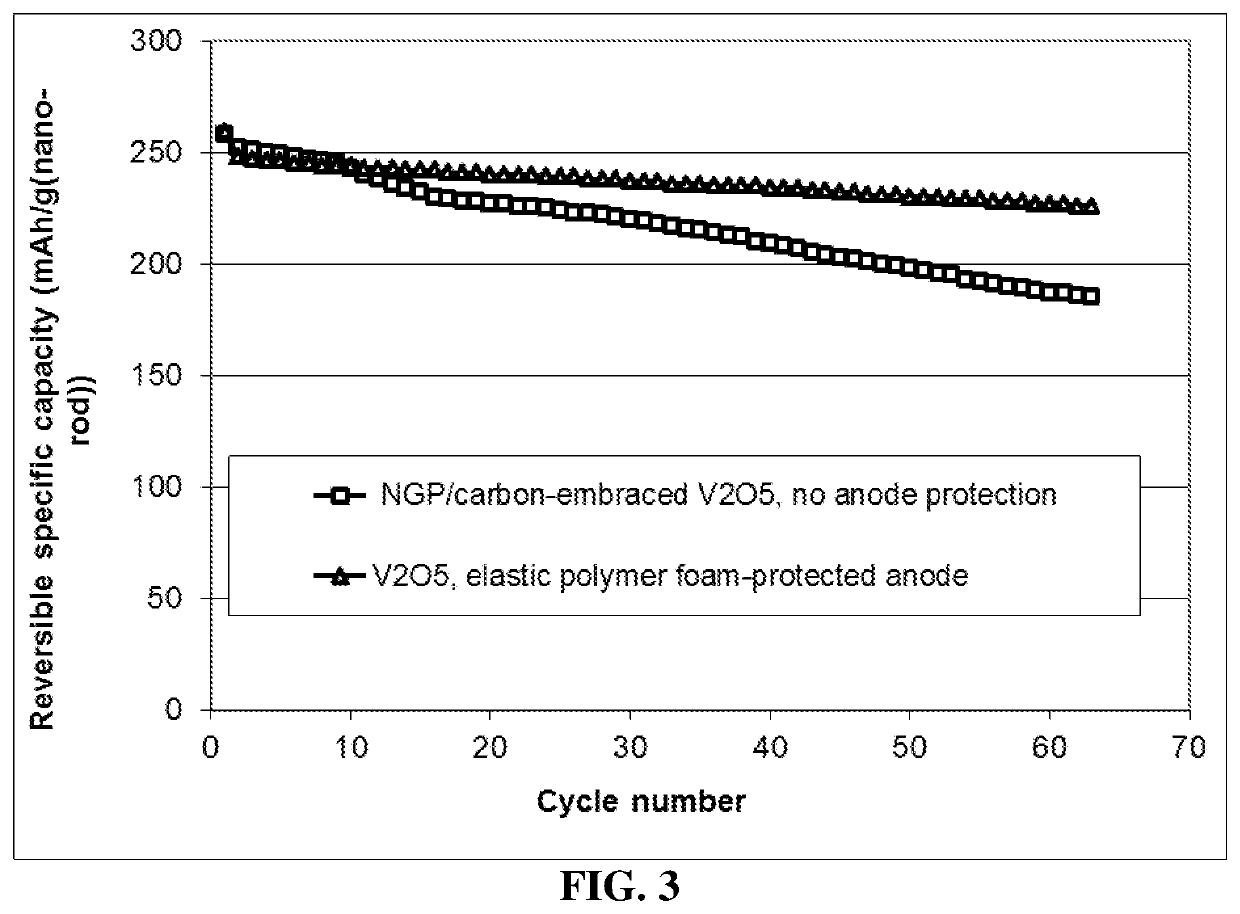

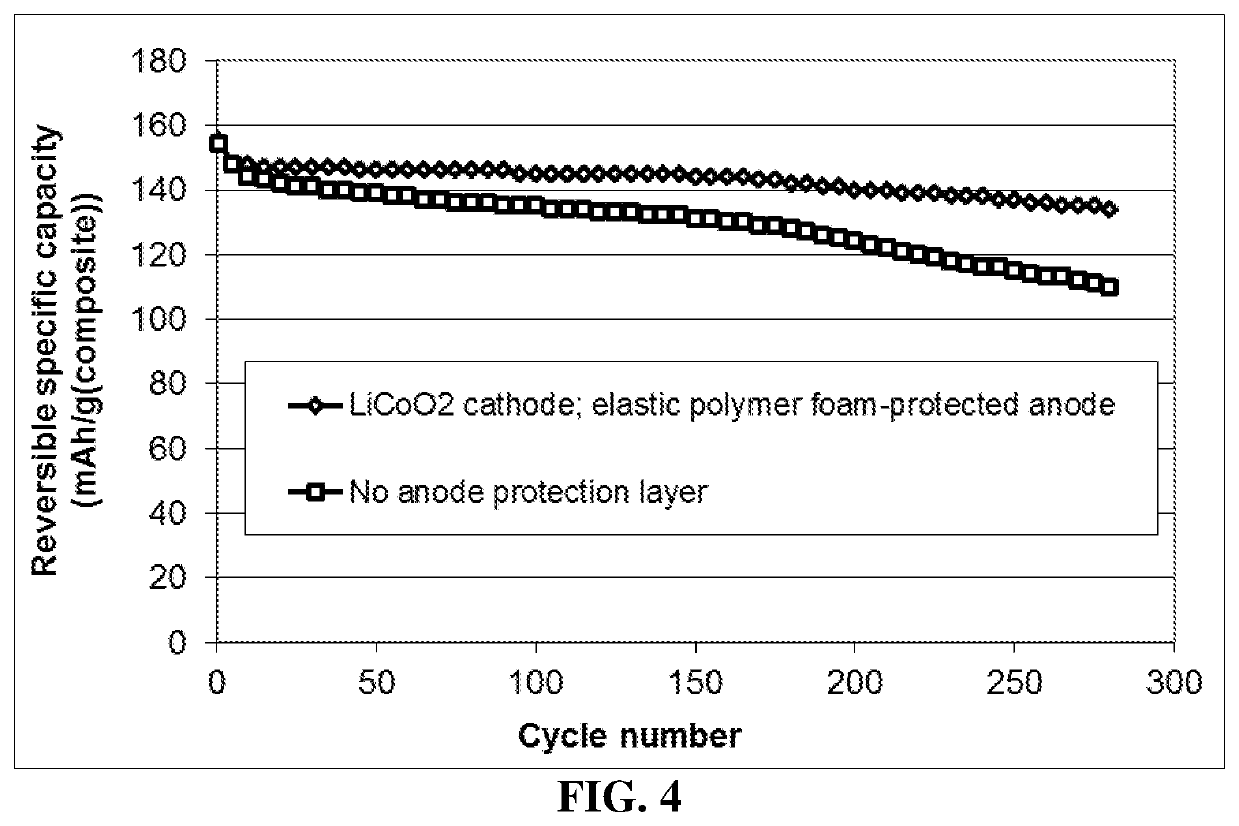

Lithium metal secondary battery containing elastic polymer foam as an anode-protecting layer

ActiveUS20200243854A1Promotes uniform depositionReducing or eliminating the lithium metal dendriteCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalAnodic protection

Provided is a lithium metal secondary battery comprising a cathode, an anode, an electrolyte-separator assembly disposed between the cathode and the anode, wherein the anode comprises: (a) an anode active material layer containing a layer of lithium or lithium alloy optionally supported by an anode current collector; and (b) an anode-protecting layer in physical contact with the anode active material layer and in ionic contact with the electrolyte-separator assembly, having a thickness from 10 nm to 500 μm and comprising an elastic polymer foam having a fully recoverable elastic compressive strain from 2% to 500% and pores having a pore volume fraction from 5% to 95% (most preferably 50-95%); wherein preferably the pores are interconnected.

Owner:GLOBAL GRAPHENE GRP INC

Lithium-ion electrochemical cell, components thereof, and methods of making and using same

ActiveUS20170149089A1Improve efficiencyProlong lifeFinal product manufactureElectrode carriers/collectorsLithiumNitrogen

An electrochemical cell including at least one nitrogen-containing compound is disclosed. The at least one nitrogen-containing compound may form part of or be included in: an anode structure, a cathode structure, an electrolyte and / or a separator of the electrochemical cell. Also disclosed is a battery including the electrochemical cell.

Owner:SION POWER CORP

Lithium-ion electrochemical cell, components thereof, and methods of making and using same

ActiveUS9577289B2Improve efficiencyProlong lifeAlkaline accumulatorsFinal product manufactureLithiumPhysical chemistry

Owner:SION POWER CORP

Method of improving the cycle stability and energy density of a lithium metal secondary battery

PendingUS20190393542A1Reduce eliminatePromotes uniform depositionFinal product manufactureCell electrodesSolid state electrolyteLithium metal

The invention provides a method of improving the cycle-life of a lithium metal secondary battery containing a non-solid state electrolyte, the method comprising implementing an anode-protecting layer between an anode active material layer and a cathode active material layer without using a porous separator, wherein the anode-protecting layer is in a close physical contact with the anode active material layer, has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm when measure at room temperature and wherein the anode active material layer contains a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material.

Owner:GLOBAL GRAPHENE GRP INC

Lithium-sulfur secondary battery containing gradient electrolyte

ActiveUS9882238B2Stable and safe anodeImprove overall utilizationElectrode carriers/collectorsLi-accumulatorsLithium sulfurSolvent

A rechargeable lithium-sulfur cell comprising a cathode, an anode, a separator electronically separating the two electrodes, a first electrolyte in contact with the cathode, and a second electrolyte in contact with the anode, wherein the first electrolyte contains a first concentration, C1, of a first lithium salt dissolved in a first solvent when the first electrolyte is brought in contact with the cathode, and the second electrolyte contains a second concentration, C2, of a second lithium salt dissolved in a second solvent when the second electrolyte is brought in contact with the anode, wherein C1 is less than C2. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Method of improving cycle-life of alkali metal-sulfur secondary battery

ActiveUS20190386347A1Reduces and eliminate shuttling effectReduce and eliminate effectCell electrodesFinal product manufactureUtilization factorSulfur content

The invention provides a method of improving the cycle-life of a rechargeable alkali metal-sulfur cell. The method comprises implementing an anode-protecting layer between an anode active material layer and a porous separator / electrolyte, and / or implementing a cathode-protecting layer between a cathode active material and the porous separator / electrolyte, wherein the anode-protecting layer or cathode-protecting layer comprises a conductive sulfonated elastomer composite having from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm when measured at room temperature. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Alkali metal-sulfur secondary battery containing a non-electronically conductive anode-protecting layer

ActiveUS20200220162A1Lower internal resistanceSmooth connectionAlkaline accumulator electrodesLi-accumulatorsConductive polymerHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, a cathode active material layer, a discrete anode-protecting layer disposed between the anode active material layer and the cathode active material layer, and an electrolyte (but no porous separator), wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm when measure at room temperature. The cathode layer comprises a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal secondary battery containing elastic polymer foam as an anode-protecting layer

ActiveUS10971725B2Promotes uniform depositionReducing or eliminating the lithium metal dendriteCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalAnodic protection

Provided is a lithium metal secondary battery comprising a cathode, an anode, an electrolyte-separator assembly disposed between the cathode and the anode, wherein the anode comprises: (a) an anode active material layer containing a layer of lithium or lithium alloy optionally supported by an anode current collector; and (b) an anode-protecting layer in physical contact with the anode active material layer and in ionic contact with the electrolyte-separator assembly, having a thickness from 10 nm to 500 μm and comprising an elastic polymer foam having a fully recoverable elastic compressive strain from 2% to 500% and pores having a pore volume fraction from 5% to 95% (most preferably 50-95%); wherein preferably the pores are interconnected.

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal secondary battery containing a protected lithium anode

ActiveUS10777810B2Reduce thicknessImprove lithium ion conductivityCell seperators/membranes/diaphragms/spacersFinal product manufactureLithium metalAnodic protection

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; (b) a first anode-protecting layer having a thickness from 1 nm to 100 μm (preferably <1 μm and more preferably <100 nm) and comprising a lithium ion-conducting material having a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm; and (c) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

Method of improving the charge/discharge cycle life and safety of an alkali metal-sulfur secondary battery

PendingUS20200220196A1Lower internal resistanceSmooth connectionSolid electrolytesFinal product manufactureElectrical batteryHigh energy

Provided is a method of improving a cycle-life of a rechargeable alkali metal-sulfur cell, the method comprising implementing an electronically non-conducting anode-protecting layer between an anode active material layer and a cathode active material without using a porous separator in the cell, wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000%, a lithium ion or sodium ion conductivity from 10−8 S / cm to 5×10−2 S / cm, and an electronic conductivity less than 10−4 S / cm when measured at room temperature. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Method of improving cycle life of a rechargeable lithium metal battery

ActiveUS20200243838A1Promotes uniform depositionReducing or eliminating the lithium metal dendriteElectrochemical processing of electrodesSecondary cellsElectrical batteryLithium metal

Provided is a method of improving the cycle-life of a lithium metal secondary battery, the method comprising implementing an anode-protecting layer between an anode active material layer (or an anode current collector layer substantially without any lithium when the battery is made) and a porous separator / electrolyte assembly, wherein the anode-protecting layer is in a close physical contact with the anode active material layer (or the anode current collector), has a thickness from 10 nm to 500 μm and comprises an elastic polymer foam having a fully recoverable compressive elastic strain from 2% to 500% and interconnected pores and wherein the anode active material layer contains a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material.

Owner:GLOBAL GRAPHENE GRP INC

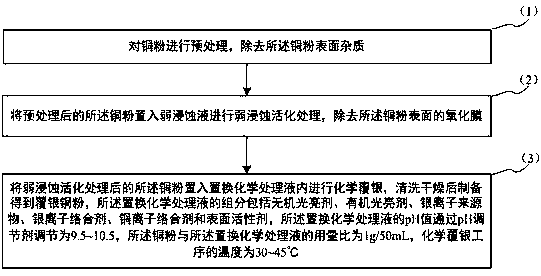

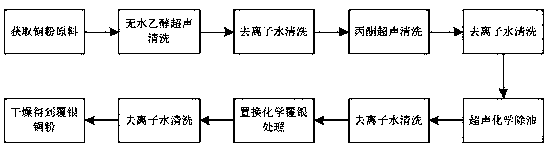

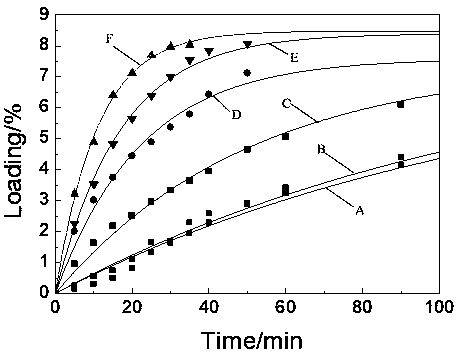

Preparation method for silver-coated copper powder

ActiveCN110369712AEasier to discharge evenlyPromotes uniform depositionTransportation and packagingMetal-working apparatusElectronic materialsCopper

The invention discloses a preparation method for silver-coated copper powder, and relates to the technical field of advanced electronic materials. The preparation method for the silver-coated copper powder reduces the concentration of silver ions on the surface of copper powder through replacement of silver ion complexing agents in chemical treatment liquid to complex the silver ions; meanwhile, copper ions are uniformly discharged more easily by copper ion complexing agents to accelerate uniform deposition of silver atoms on the surface of the copper powder; and the silver ion complexing agents and the copper ion complexing agents achieve a cooperative acceleration effect, so that the complexing efficiency of the silver ions and the copper ions on the surface of the copper powder is improved, the deposition speed of the silver atoms on the surface of the copper powder is further accelerated, the quick generation and the uniform coverage of silver coating layers on the surface of the copper powder are realized, the technical problems of lower silver coating efficiency on the surface of traditional silver-coated copper powder and weaker quality of the silver coating layers are solved, and the technical effects of improving the surface silver coating effect of the silver-coated copper powder and the silver coating quality are achieved.

Owner:JIAXING UNIV +1

Lithium metal secondary battery containing two anode-protecting layers

ActiveUS10784509B2Decrease exchange current densityPromotes uniform depositionSolid electrolytesFinal product manufactureElastomerConductive polymer

Owner:GLOBAL GRAPHENE GRP INC

Alkali metal-sulfur secondary battery containing a non-electronically conductive anode-protecting layer

ActiveUS11024840B2Improve cycle lifeHigh sulfur contentAlkaline accumulator electrodesSecondary cells charging/dischargingConductive polymerHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, a cathode active material layer, a discrete anode-protecting layer disposed between the anode active material layer and the cathode active material layer, and an electrolyte (but no porous separator), wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm when measure at room temperature. The cathode layer comprises a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Alkali metal-sulfur secondary battery containing a conductive electrode-protecting layer

ActiveUS10862157B2Improve cycle lifeReduce impactCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsElectrical batteryHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode layer, an electrolyte and a porous separator, a cathode layer, and a discrete anode-protecting layer disposed between the anode layer and the separator and / or a discrete cathode-protecting layer disposed between the separator and the cathode active material layer; wherein the anode-protecting layer or cathode-protecting layer comprises a conductive sulfonated elastomer composite having from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material and the protective layer has a thickness from 1 nm to 50 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal secondary battery containing an electrochemically stable anode-protecting layer

ActiveUS10734646B2Impart stabilityLower resistanceNegative electrodesPositive electrodesElectrical batteryLithium metal

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal secondary battery featuring an anode-protecting layer

ActiveUS10727531B2Reduce thicknessImprove lithium ion conductivityCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalElastomer composites

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte disposed between the cathode and the anode, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; and (b) an anode-protecting layer of a conductive sulfonated elastomer composite, disposed between the anode active layer and the separator / electrolyte; wherein the composite has from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

Apparatus, method and system for fabricating a patterned media imprint master

InactiveUS7667929B2Easy to operatePromotes uniform depositionNanoinformaticsPatterned record carriersEngineeringDeposition process

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com