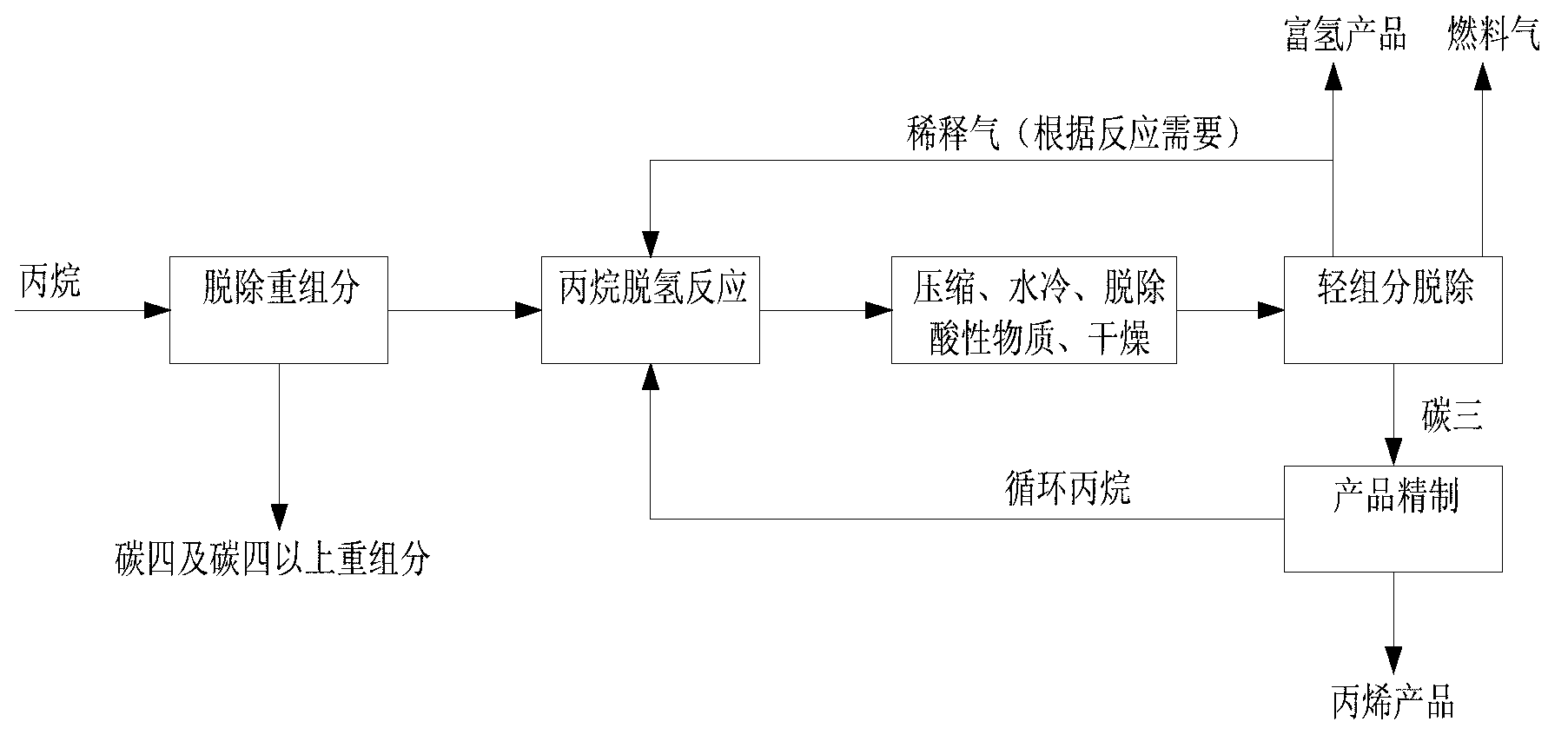

Method for separating reaction products produced during preparation of propylene by dehydrogenating propane

A technology for propane dehydrogenation and reaction products, which is applied in distillation purification/separation, diaphragm purification/separation, sustainable manufacturing/processing, etc. Suitability and other issues to achieve the effect of saving equipment costs, high recovery rate and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

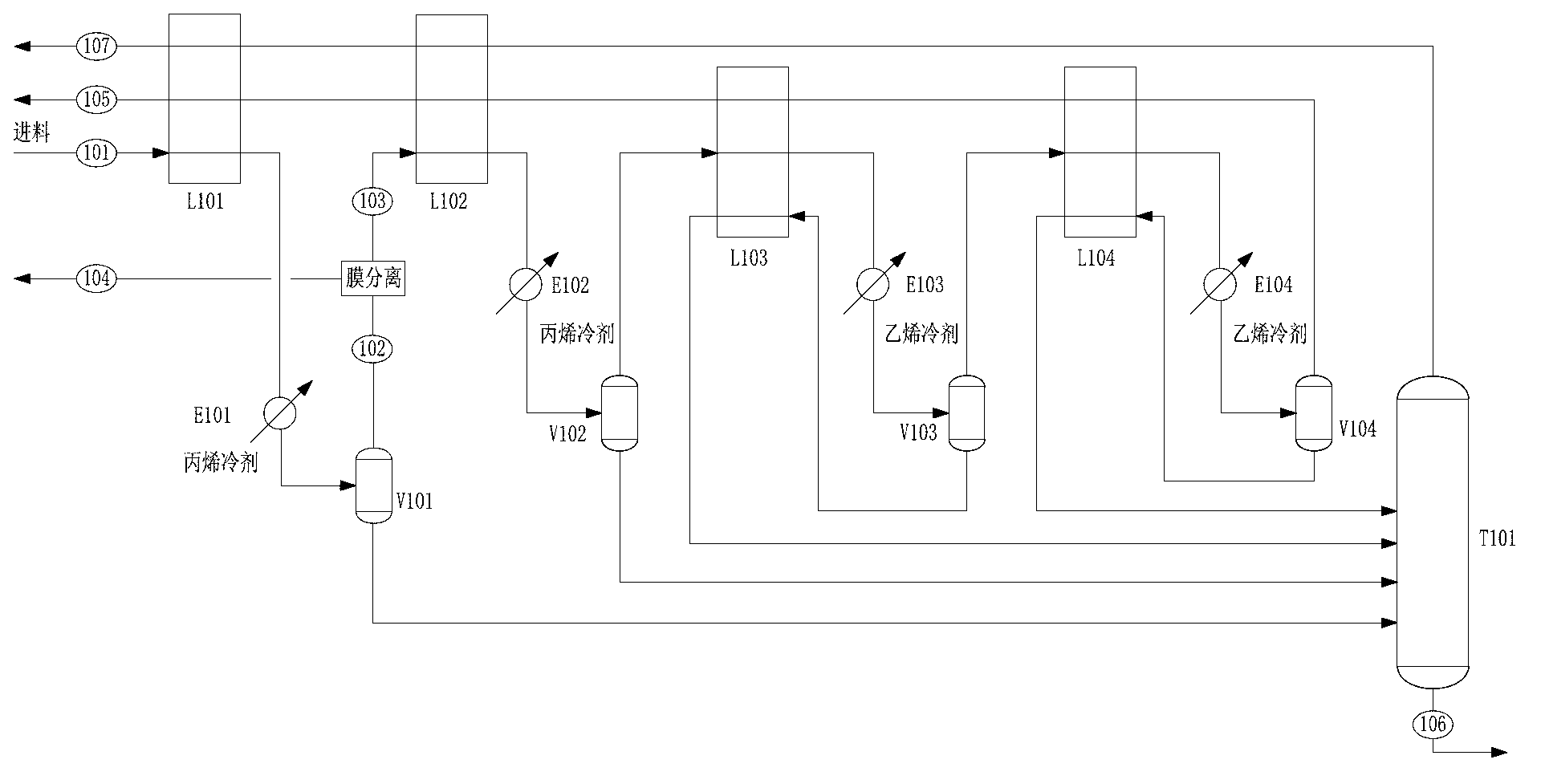

[0046] The process is attached figure 2 Shown, the material balance table of embodiment 1 is as shown in table 1.

[0047] A certain propane dehydrogenation to propylene reaction product is compressed to 1.8 MPa, and after water cooling, removal of acidic substances and drying, it enters the separation process and is used as the feed of the separation system. The composition is shown in Table 1, stream 101. The stream 101 is cooled and condensed through the process stream and propylene refrigerant in the first cold box L101 and the first heat exchanger E101 in turn, the temperature is lowered to -20°C, and it enters the first-stage flash tank V101. The gas phase 102 at the top of the first-stage flash tank V101 is sent to the membrane separation unit; the liquid phase at the bottom of the tank is sent to the deethanizer T101.

[0048] The feed composition of the membrane separation unit is shown in the stream 102 in Table 1, and the membrane separation unit is separated into...

Embodiment 2

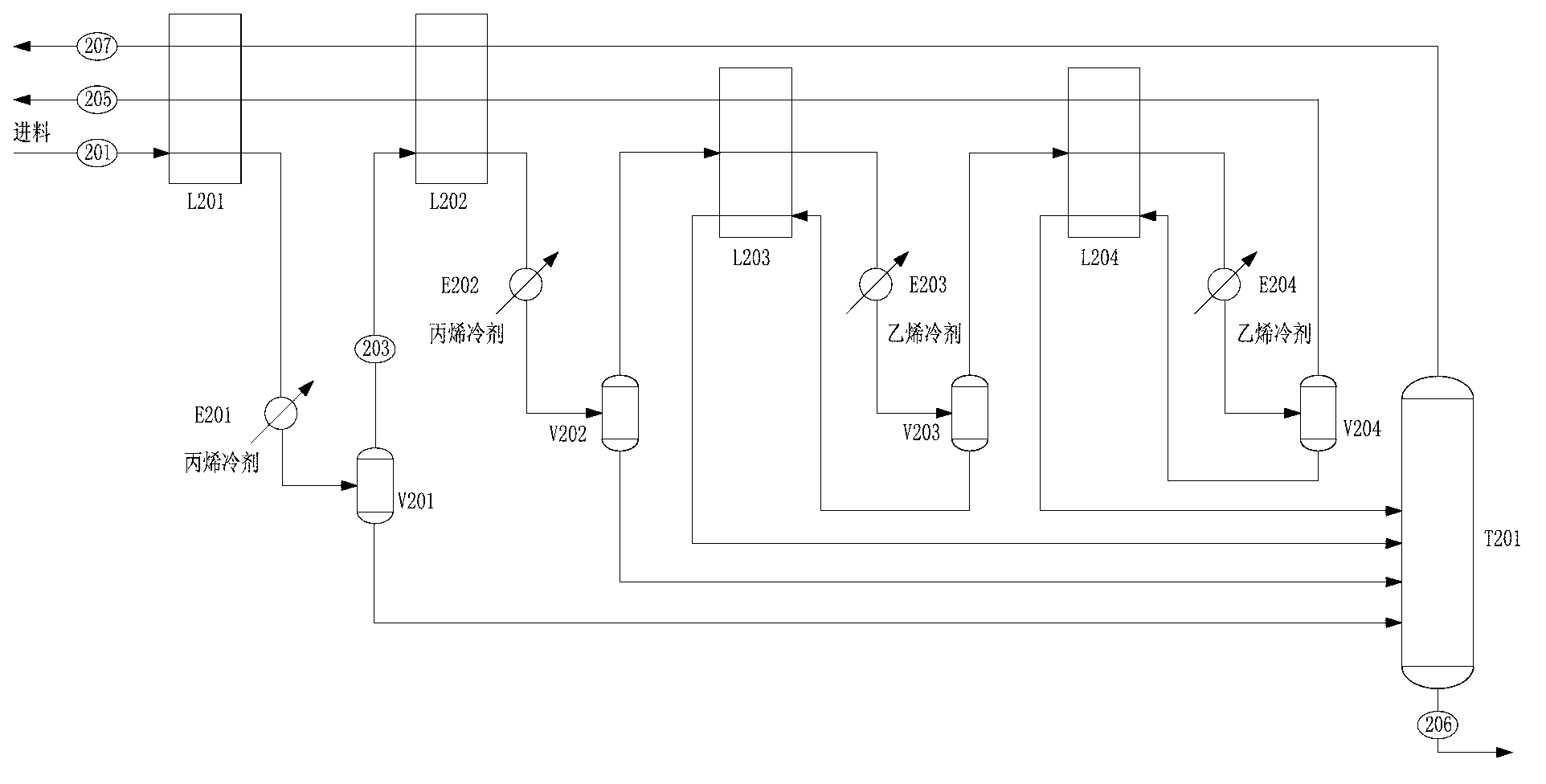

[0066] The process is attached Figure 4 Shown, the material balance table of embodiment 2 is as shown in table 4.

[0067] A certain propane dehydrogenation to propylene reaction product is compressed to 1.0 MPa, and after water cooling, removal of acidic substances and drying, it enters the separation process and is used as the feed of the separation system. The composition is shown in Table 4, stream 301. The stream 301 enters the membrane separation unit and is separated into a hydrogen-rich permeate gas 304 and a hydrocarbon-rich non-permeate stream 303 through the membrane separation unit. The hydrogen purity of membrane-separated permeate gas 304 is higher than 96 mol%, and the hydrogen recovery rate is 35%. Membrane separation unit includes membrane separation feed demister, heating and membrane separator. The temperature of the membrane separator was 50°C. The inlet gas pressure of the membrane separation unit is 0.9 MPa, the pressure of membrane separation permeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com