Mushroom-shaped mixed composite pile capable of effectively controlling settlement and construction method

A construction method, mushroom-shaped technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low strength of pile body, high construction cost, high cement consumption, etc., and achieve good settlement effect, economical and environmental protection noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

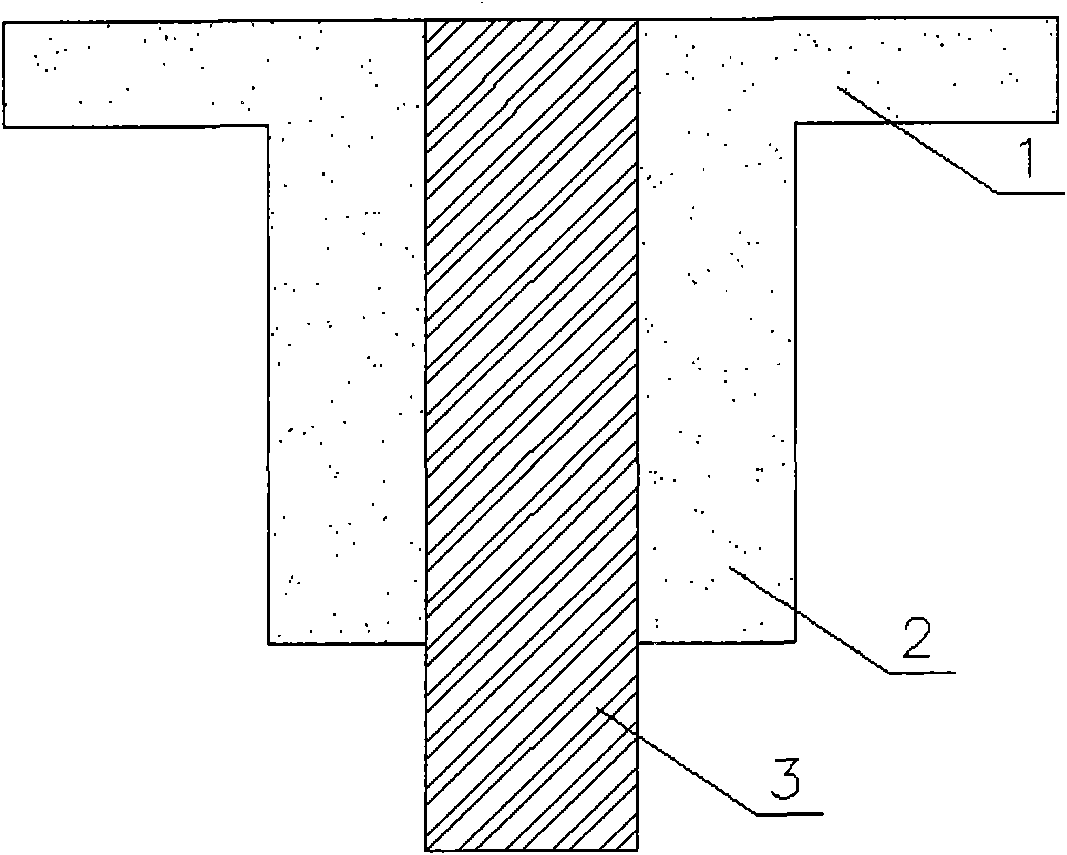

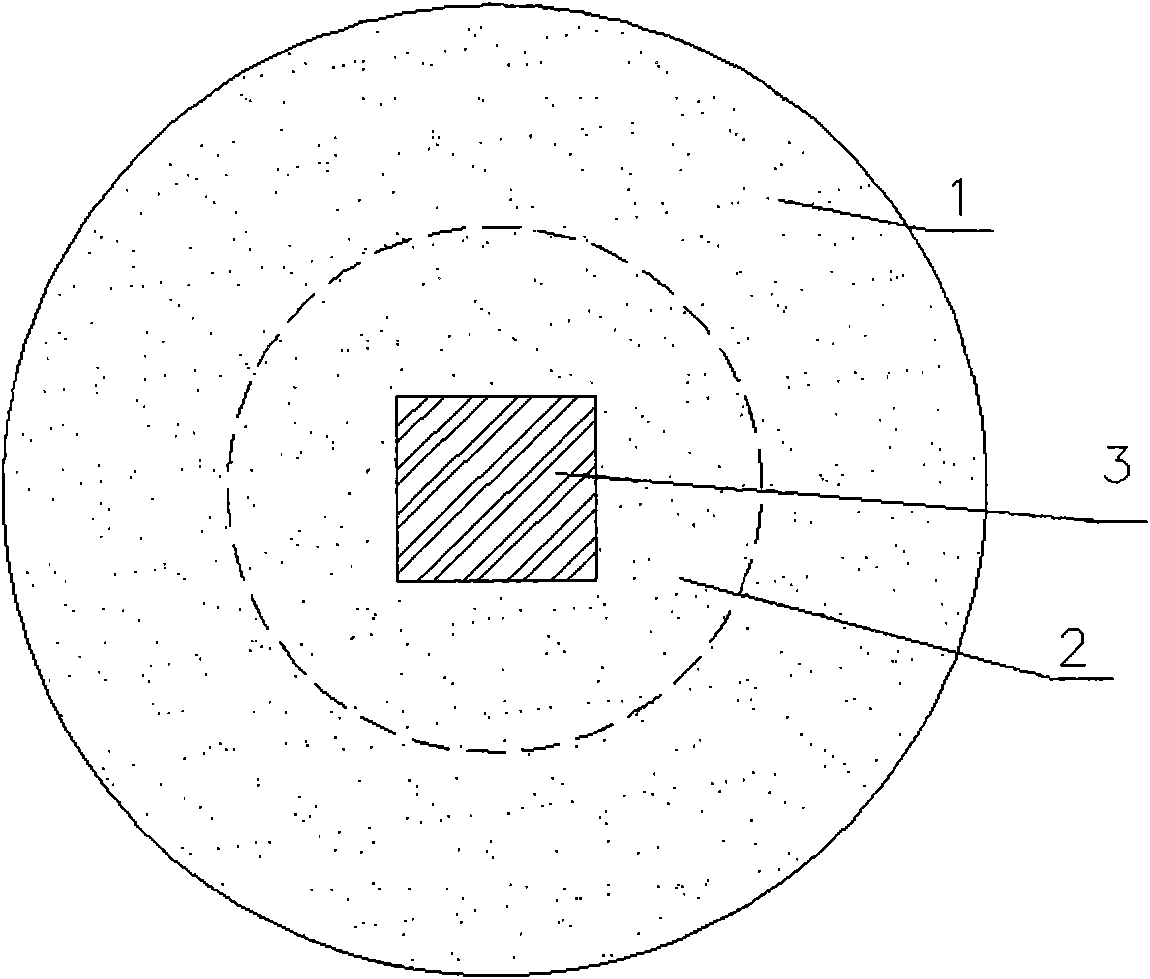

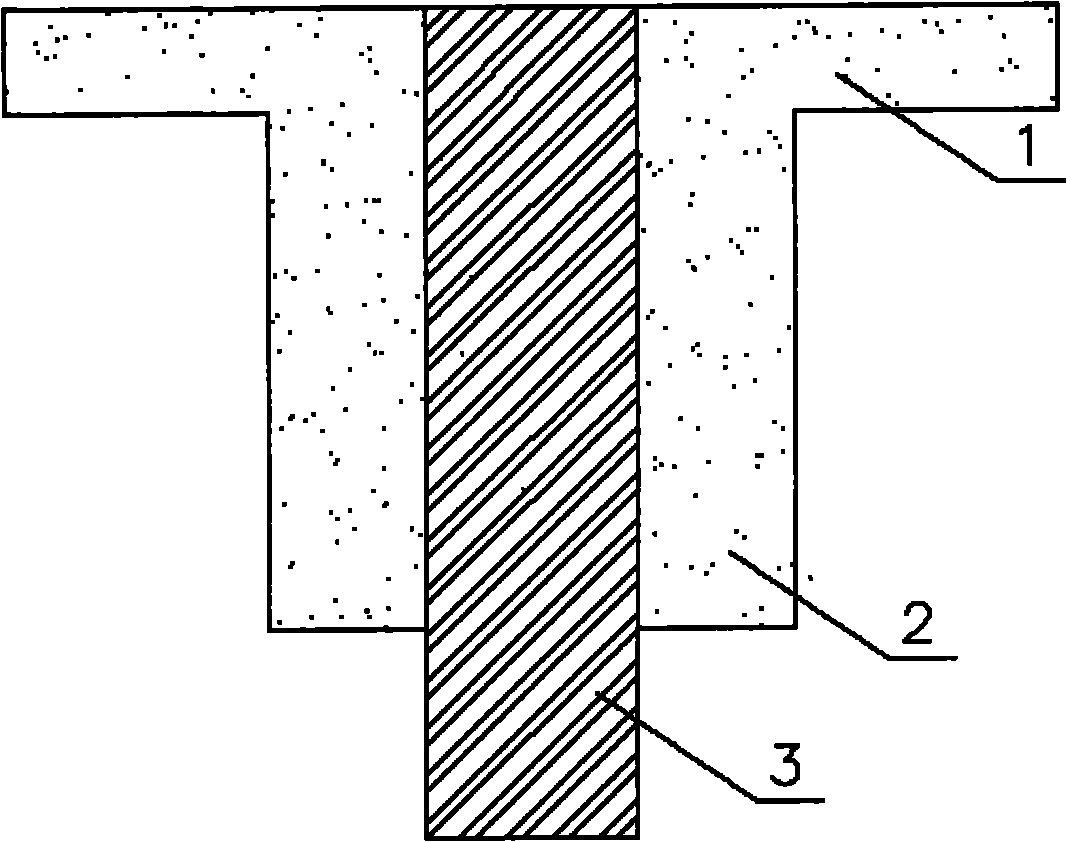

[0019] (1) First, use a single-axis variable-diameter mixing pile driver to mix the soil with the cement slurry to form a mushroom-shaped cement-soil mixing pile.

[0020] (2) Then insert one (or several) core materials (prefabricated concrete square piles, or steel pipes, or steel bars, or bamboo and wood materials) into a composite pile body through vibration or self-weight.

[0021] (3) The added core material should be in the center of the mushroom-shaped cement-soil mixing pile, that is, the center of the inserted core material should coincide with the center of the mixing pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com