Injection device for discharging accumulated fluids in shaft

A liquid effusion and wellbore technology, applied in jet pumps, non-displacement pumps, wellbore/well components, etc., can solve the problems of slow plunger down, limited liquid discharge, formation pollution, etc., and increase the production pressure difference , The structure of the equipment is simple, and the effect of reducing back pressure at the bottom of the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

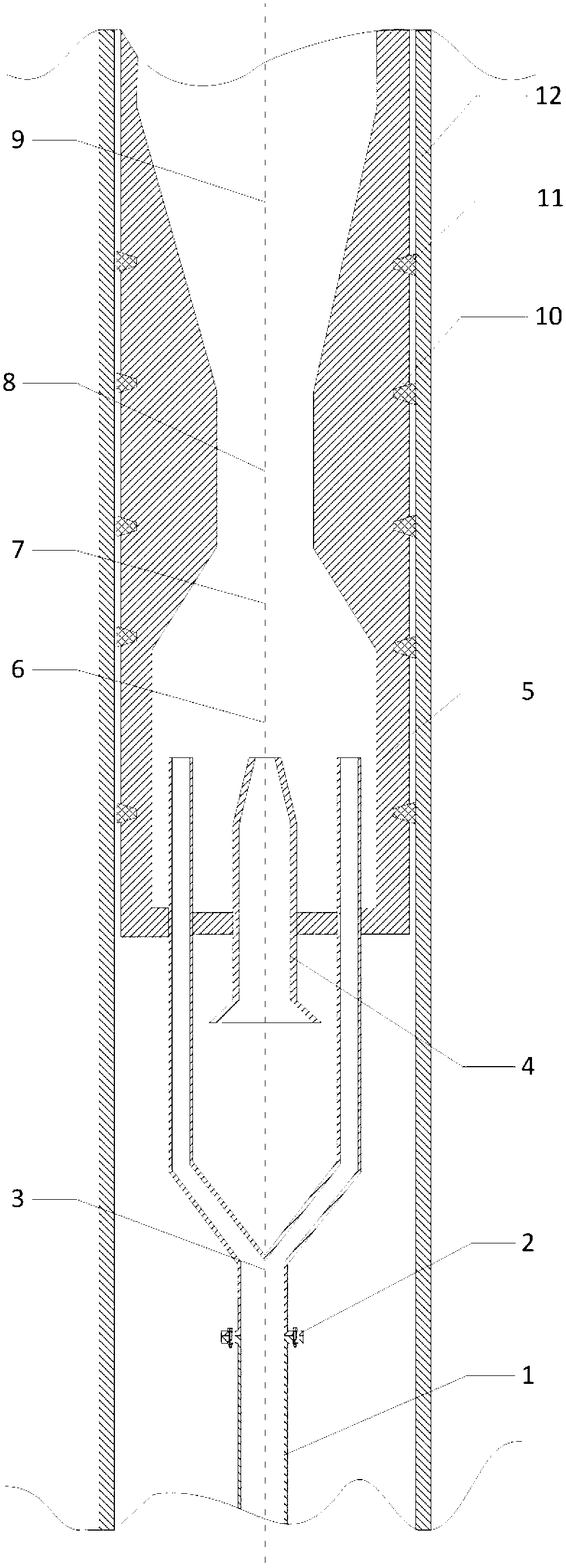

[0029] see figure 1 , an injection device for removing wellbore fluid, including a main cylinder 5 with a suction chamber 6, and the main cylinder 5 includes a suction chamber 6, a throat section 8 and a diffuser section connected in sequence from bottom to top 9. The suction chamber 6 includes a straight pipe section and a shrinkage pipe section 7, the diameter of the shrinkage pipe section 7 decreases linearly from bottom to top, and the angle between the wall line of the shrinkage pipe section 7 and the central axis of the main cylinder 5 is 45° °; the pipeline of the throat section 8 is a straight tube type; the pipe diameter of the diffuser section 9 increases linearly from bottom to top, and the dimensions of each section in the main cylinder 5 should be designed according to different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com