Helium leakage test device and method

A technology of leak detection and helium gas, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc. High cost and other problems, to achieve the effect of simple structure, low test cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

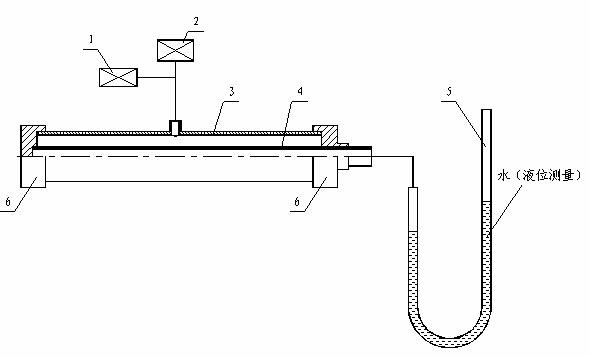

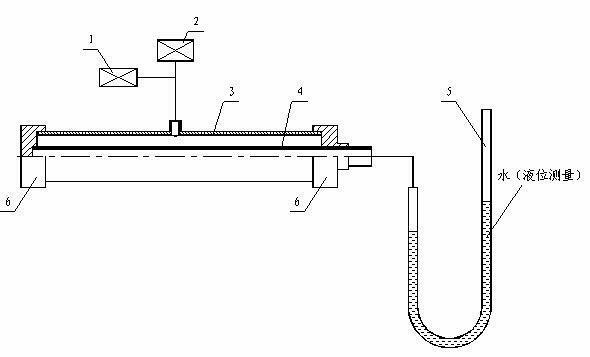

[0011] The device is composed of a test piece pressure system, a test medium supply system, and a test data acquisition system. The pressure system for carrying the test piece is composed of a pressure vessel 3 and a vacuum device 1 . The test piece 4 is first installed in the pressure vessel 3, and one end of the test piece 4 is kept connected to the test data acquisition system, and the test medium supply system is connected to the pressurized system carrying the test piece. Pressure vessel with high airtightness3. The test piece 4 can be installed in the pressure vessel 3, can be directly connected with the test data acquisition system, and can ensure the sealing requirements of the whole test system. The test medium supply system consists of a helium storage tank 2, a pressure gauge and a safety valve. The present invention has a movable structure, and each part is easy to install and connect. When in use, the pressure vessel 3 is opened first, the test piece 4 is sealed...

Embodiment 2

[0013] Take a Φ16 / Φ24 polytetrafluoroethylene insulated water diversion pipe, and cut a length of 600mm as a test piece. Install the test piece in the pressure vessel, keep one end of the test piece connected to the test data acquisition system, and record the initial data as 11mm. Keep the test medium supply system connected to the pressure system of the bearing specimen, and pre-evacuate the pressure system of the bearing specimen. Open the test medium supply system to fill the pressure vessel with helium, stop the helium filling after pressurizing to 6 bar, record the test data every few hours and fill the pressure with helium. After 24 hours, the final data recorded is 65mm, and the helium diffusion amount per centimeter length of the test piece within 24 hours is calculated to be 1.22 cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com