Diffusion welding piece of high-purity zirconium oxide composite ceramic and red copper and production method of diffusion welding piece

A technology of zirconia ceramics and composite ceramics, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., and can solve problems such as diffusion welding methods between zirconia ceramics and copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

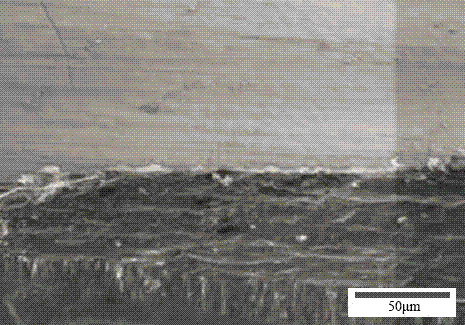

Image

Examples

Embodiment Construction

[0131] The invention relates to a diffusion welded piece of high-purity zirconia composite ceramics and red copper and a production method thereof. The specific implementation steps are as follows.

[0132] (1) Choose zirconia composite ceramics with 3% yttrium oxide molar percentage, which contains 2% hafnium oxide by weight, 3% aluminum oxide by weight, 2% calcium oxide by weight and 0.5% erbium oxide by weight, and the zirconia composite The relative density of the ceramics is 96.3%, the grain size of the zirconia composite ceramics is 5.4 microns, and the purity of the core elements of the zirconia composite ceramics is 99.995%. The surface is ground with a 60-mesh diamond grinding wheel and cleaned and dried.

[0133] (2) Select a copper plate with a purity of 99.9%, and use 40-mesh brown corundum sand to blast the copper plate and then clean and dry it.

[0134] (3) The welding surface of the composite zirconia ceramic obtained in step (1) is subjected to vacuum ion plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com