Top gas confluence method and device of atmospheric and vacuum distillation tower

An atmospheric tower and gas technology, applied in hydrocarbon distillation, petroleum industry, machines/engines, etc., can solve problems such as low extraction rate of vacuum tower, increased stream flow resistance loss, pressure fluctuation of vacuum tower, etc. Achieve the effects of simple process flow, easy implementation and easy transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

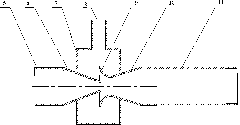

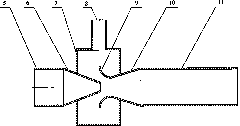

[0027] Example 1. refer to figure 1 and figure 2 . The positive-pressure gas gas (acting as injection medium) separated from the mixed gas tank at the top of the initial distillation tower and the top of the atmospheric pressure tower passes through the primary and constant top gas pipelines 1, enters the injection medium inlet pipe 5 of the confluence 3, and then passes through the confluence After the nozzle 6 is ejected, a flow stream with a higher flow velocity and a constricted vein is produced, and the constricted vein becomes the position with the lowest pressure and the highest suction capacity. The slightly positive pressure gas gas separated from the gas tank at the top of the decompression tower (as the medium to be injected), under the suction of the injection medium, first enters the suction pipe of the medium to be injected in the confluence along the top-reducing gas pipeline 2 8, and then enter the suction chamber 7. The gas to be ejected that enters the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com