Method for welding tantalum layers to six faces of tungsten block in diffusion manner

A technology of tungsten block and tantalum sheet, which is applied in the field of welding of refractory metals, can solve the problems of expensive target components of tantalum-tungsten composite material, many electron beam welding processes, oxidation of tantalum surface, etc., so as to achieve low cost and reduce production cost. , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

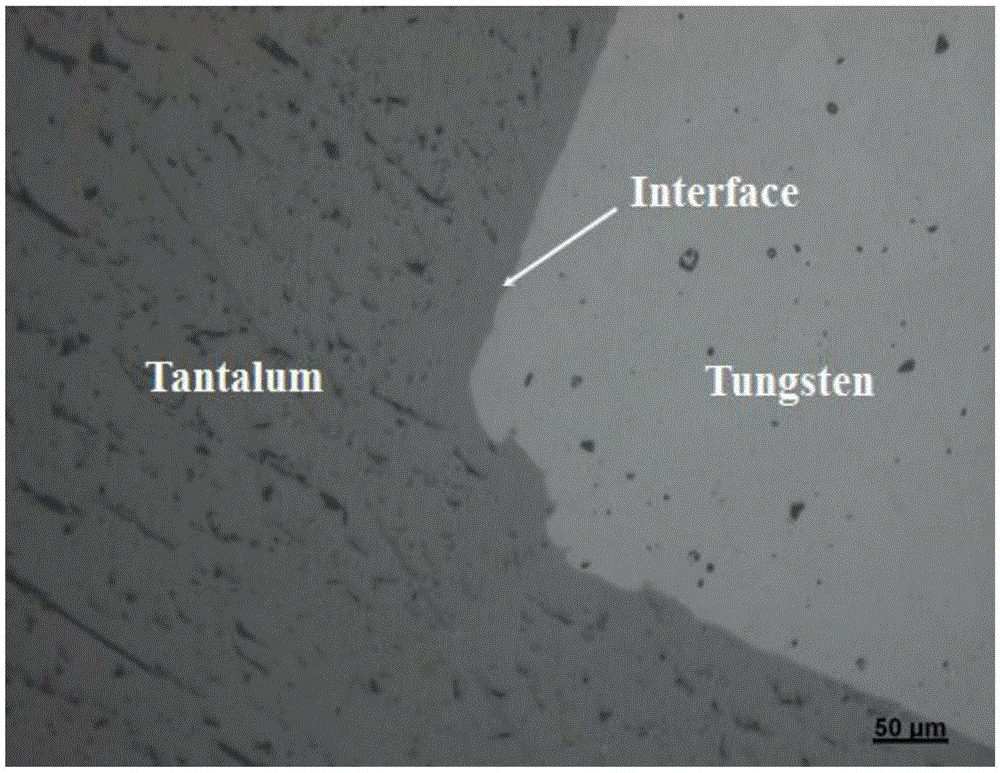

Image

Examples

Embodiment

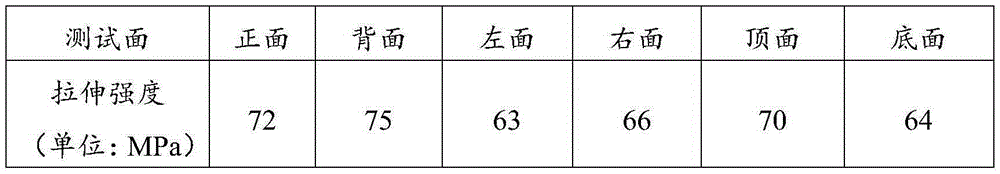

[0029]The tungsten block to be processed in this example is a cuboid whose dimensions are 170mm×70mm×26mm in length×width×height. Therefore, in this example, a cylindrical titanium metal block with a diameter of 250 mm and a height of 34 mm is used to make the outer casing. Specifically, a square through hole with a length × width of 178.1 mm × 78.1 mm is cut in the height direction of the titanium metal cylinder. The square through hole runs through the titanium metal cylinder to obtain the titanium metal outer sheath of this example. At the same time, two titanium discs with a diameter of 250 mm and a thickness of 2 mm are prepared as caps. The dimensions of the six tantalum sheets are respectively, two tantalum sheets with length×width×thickness 174mm×74mm×2mm, two tantalum sheets with length×width×thickness 174mm×26mm×2mm, two tantalum sheets with length×width×thickness It is a tantalum sheet of 70mm×26mm×2mm, a total of six tantalum sheets, which are respectively attache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com