High-temperature anti-rutting modified asphalt and preparation method thereof

A modified asphalt, anti-rutting technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of easy formation of rutting, sticky asphalt materials, etc., to prolong service life, good dispersion, and reduce high temperature sensitivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

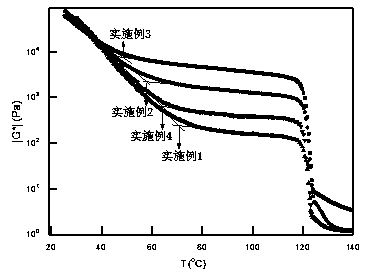

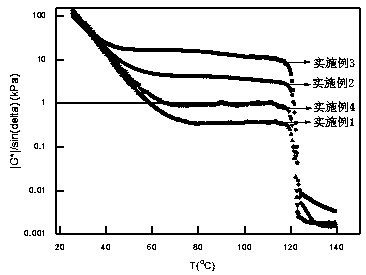

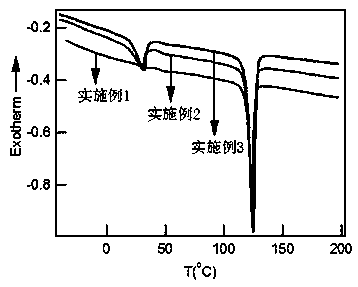

Embodiment 1

[0029] A high-temperature anti-rutting modified asphalt is composed of the following raw materials in parts by weight: 100 parts of 70# base asphalt, 10 parts of polyethylene (HDPE), and 0 parts of polyethylene glycol (PEG-800). Among them, the molecular weight range of polyethylene is 10 4 ~10 5 g / mol, melt flow rate > 0.4 g / 10 min at 190°C.

[0030]The preparation method of the high-temperature anti-rutting modified asphalt comprises the following steps:

[0031] (1) Heat 70# base asphalt to 100°C to soften it;

[0032] (2) Add polyethylene to 70# base asphalt to obtain a mixture. After heating to 180°C, turn on the constant temperature and low-speed stirring, the stirring speed is 500rpm, and the stirring time is 30min;

[0033] (3) At the same temperature, the mixture described in step 2) was further subjected to high-speed shearing at a shearing speed of 5000 rpm and a shearing time of 2 hours to obtain the high-temperature anti-rutting modified asphalt.

Embodiment 2

[0035] A high-temperature anti-rutting modified asphalt is composed of the following raw materials in parts by weight: 100 parts of 90# base asphalt, 10 parts of polyethylene (HDPE), and 5 parts of polyethylene glycol (PEG-800). Among them, the molecular weight range of polyethylene is 10 4 ~10 5 g / mol, melt flow rate > 0.4 g / 10 min at 190°C.

[0036] The preparation method of the high-temperature anti-rutting modified asphalt comprises the following steps:

[0037] (1) Heat 90# base asphalt to 100°C for softening;

[0038] (2) Add polyethylene glycol and polyethylene to 90# base asphalt, after heating to 180°C, start constant temperature and low-speed stirring, the stirring speed is 500rpm, and the stirring time is 30min;

[0039] (3) At the same temperature, the asphalt was further subjected to high-speed shearing, the shearing speed was 5000 rpm, and the shearing time was 2 hours, to obtain the high-temperature anti-rutting modified asphalt.

Embodiment 3

[0041] A high-temperature anti-rutting modified asphalt is composed of the following raw materials in parts by weight: 100 parts of 70# base asphalt, 10 parts of polyethylene (HDPE), and 10 parts of polyethylene glycol (PEG-800). Among them, the molecular weight range of polyethylene is 10 4 ~10 5 g / mol, melt flow rate > 0.4 g / 10 min at 190°C.

[0042] The preparation method of the above-mentioned high-temperature anti-rutting modified asphalt comprises the following steps:

[0043] (1) Heat 70# base asphalt to 100°C to soften it;

[0044] (2) Add polyethylene glycol and polyethylene to 70# base asphalt to obtain a mixture. After heating to 180°C, start stirring at a constant temperature and low speed. The stirring speed is 500rpm and the stirring time is 30min;

[0045] (3) At the same temperature, further perform high-speed shearing on the mixture described in step 2), the shearing speed is 5000 rpm, and the shearing time is 2 hours, to obtain the high-temperature anti-ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com