Refractory castable for blast furnace tapping trench and preparation method thereof

A technology for refractory castables and blast furnace tapping, which is applied in the field of preparation of refractory castables for blast furnace tapping trenches, can solve the problems of long construction period, large energy consumption, short service life, etc. Strength, effect of increasing sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

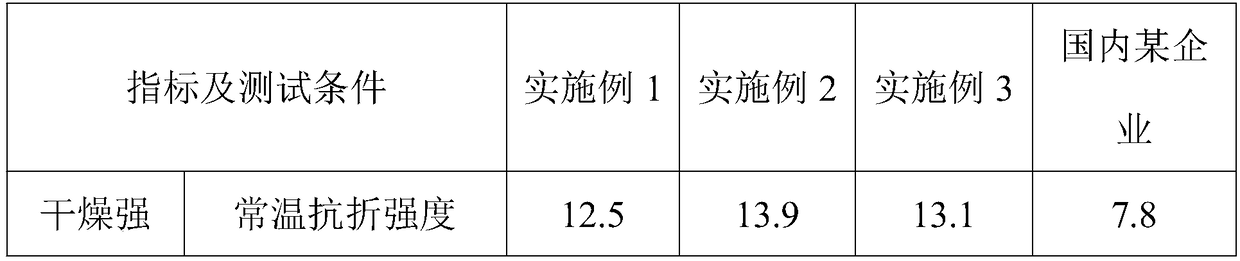

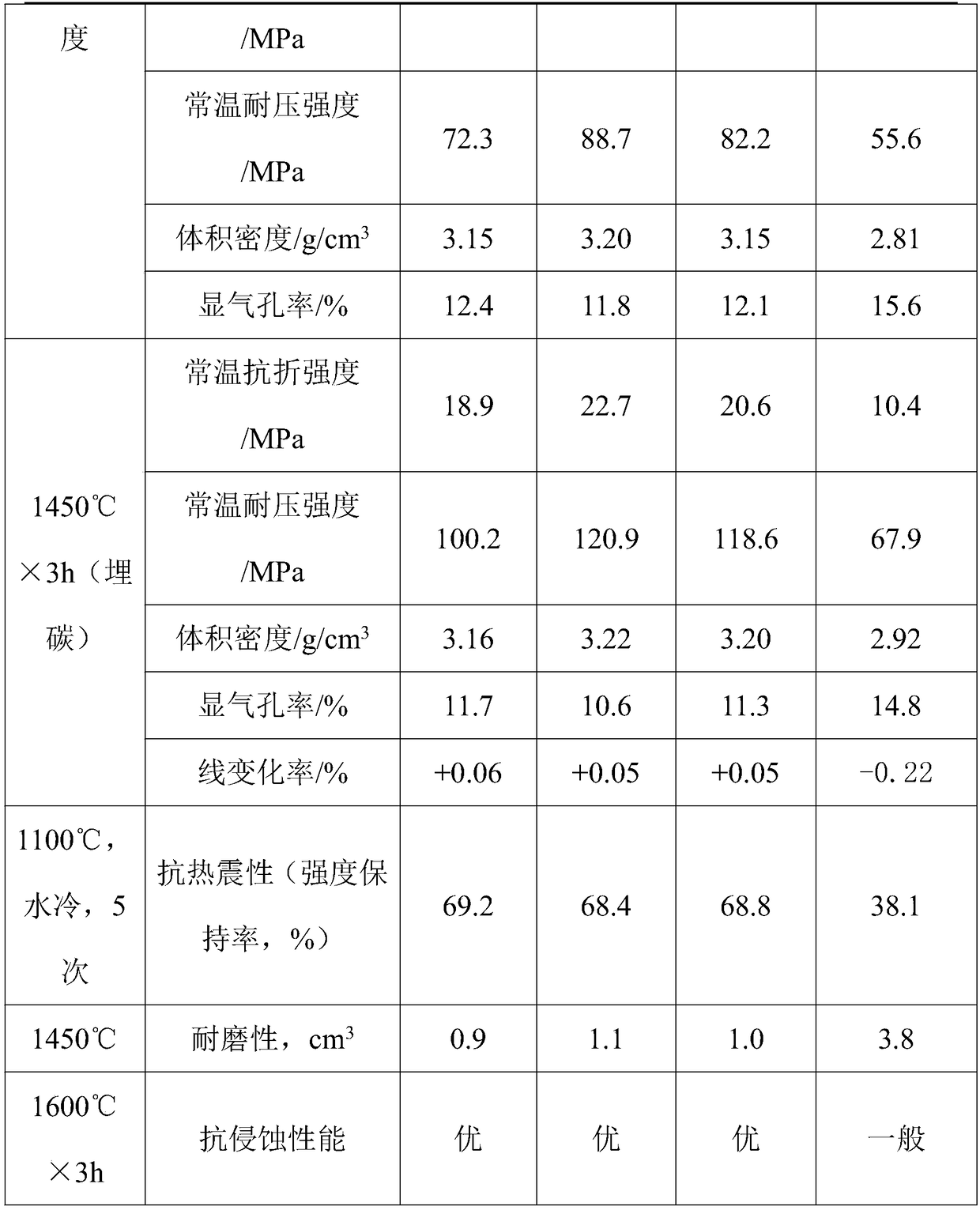

Embodiment 1

[0040] First, premix A of fused white corundum powder, silicon carbide powder, silicon micropowder, calcined alumina powder, pure calcium aluminate cement and metal silicon powder; spherical asphalt, high-efficiency anti-explosion agent and high-efficiency dispersant are prefabricated into mixture B , Shanxi high-quality high-alumina bauxite and electric fused brown corundum of two particle sizes are prefabricated into coarse aggregate C in a mixer and stirred evenly, and materials A, B and C are packaged separately. When preparing castables, add premix A and premix B to material C and add them to a forced mixer for dry mixing. When stirring, add high-efficiency water reducer and stir evenly, then put them into a large bag to obtain dry refractory castables; Pour the dry material into the mixer, add tap water at room temperature while stirring, and mix well. After mixing evenly, it can be poured into a shape, and then it can be put into use after curing, demoulding, and rapid b...

Embodiment 2

[0057] First, premix A of fused white corundum powder, silicon carbide powder, silicon micropowder, calcined alumina powder, pure calcium aluminate cement and metal silicon powder; spherical asphalt, high-efficiency anti-explosion agent and high-efficiency dispersant are prefabricated into mixture B , Shanxi high-quality high-alumina bauxite and electric fused brown corundum of two particle sizes are prefabricated into coarse aggregate C in a mixer and stirred evenly, and materials A, B and C are packaged separately. When preparing castables, add premix A and premix B to material C and add them to a forced mixer for dry mixing. When stirring, add high-efficiency water reducer and stir evenly, then put them into a large bag to obtain dry refractory castables; Pour the dry material into the mixer, add tap water at room temperature while stirring, and mix well. After mixing evenly, it can be poured into a shape, and then it can be put into use after curing, demoulding, and rapid b...

Embodiment 3

[0074] First, premix A of fused white corundum powder, silicon carbide powder, silicon micropowder, calcined alumina powder, pure calcium aluminate cement and metal silicon powder; spherical asphalt, high-efficiency anti-explosion agent and high-efficiency dispersant are prefabricated into mixture B , Shanxi high-quality high-alumina bauxite and electric fused brown corundum of two particle sizes are prefabricated into coarse aggregate C in a mixer and stirred evenly, and materials A, B and C are packaged separately. When preparing castables, add premix A and premix B to material C and add them to a forced mixer for dry mixing. When stirring, add high-efficiency water reducer and stir evenly, then put them into a large bag to obtain dry refractory castables; Pour the dry material into the mixer, add tap water at room temperature while stirring, and mix well. After mixing evenly, it can be poured into a shape, and then it can be put into use after curing, demoulding, and rapid b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com