High-temperature abrasion resistant composite material and preparation method thereof

A composite material, high temperature wear resistance technology, applied in the field of copper matrix composite materials, can solve the problems of poor toughening and high temperature resistance, low strength at room temperature and high temperature, difficult forming, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The high-temperature wear-resistant composite material prepared in Example 1 includes the following components in terms of mass percentage:

[0098] Electrolytic copper powder 72%, short carbon fiber 2.0%, flake graphite powder 15.0%, fine alumina powder 1.0%, coarse alumina powder 10.0%. The particle size of electrolytic copper powder is 45 μm, the diameter of short carbon fiber is 7 μm, and the length is 2 mm, the particle size of flake graphite powder is 50 μm, the particle size of coarse alumina powder is 150 μm, and the particle size of fine alumina powder is 3 μm.

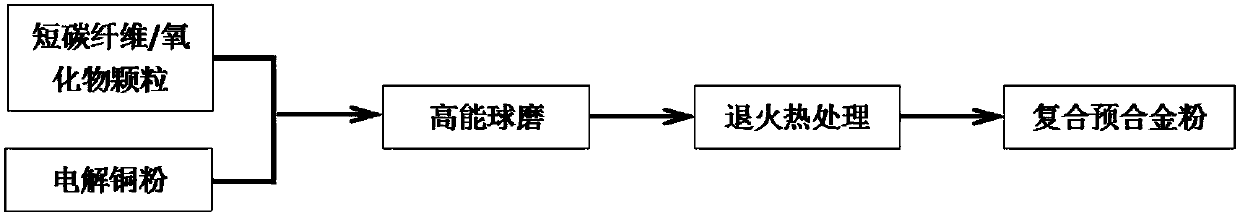

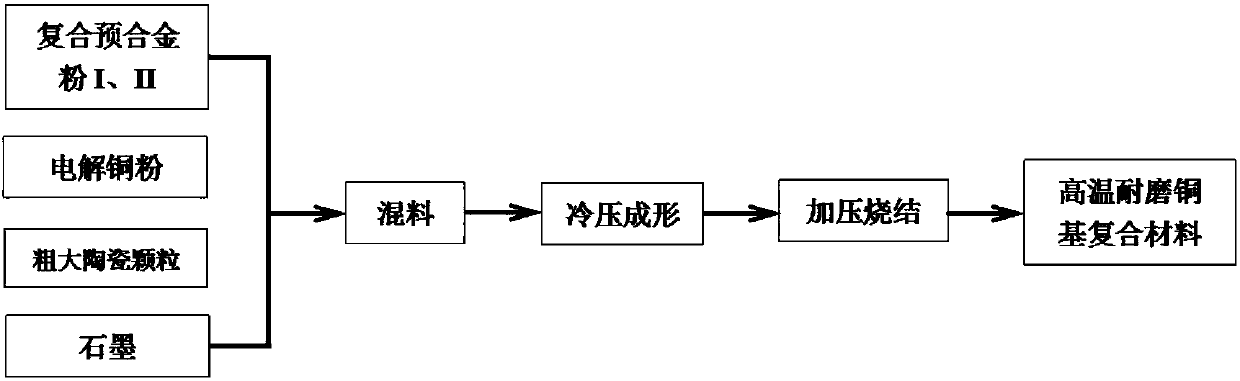

[0099] Firstly, the composite pre-alloyed powder I of short carbon fiber and copper powder is prepared, which includes the following components in terms of mass percentage: electrolytic copper powder 96%, short carbon fiber 4.0%. The electrolytic copper powder and short carbon fiber are subjected to high-energy ball milling, the ball milling speed is 260 rpm, and the ball milling time is 8 hours; final...

Embodiment 2

[0103] The high-temperature wear-resistant composite material prepared in Example 2 includes the following components in terms of mass percentage:

[0104] Electrolytic copper powder 81%, flake graphite powder 9.0%, fine zirconia powder 1.0%, coarse alumina powder 8.0%, silicon oxide powder 1.0%, short carbon fiber 2.5%. The particle size of electrolytic copper powder is 60 μm, the particle size of flake graphite powder is 40 μm, the particle size of fine zirconia powder is 2 μm, the particle size of coarse alumina powder is 120 μm, the particle size of silica powder is 50 μm, the diameter of short carbon fiber is 8 μm, the length 2mm.

[0105] Firstly, the composite pre-alloyed powder I of short carbon fiber and copper powder is prepared, which includes the following components in terms of mass percentage: electrolytic copper powder 95%, short carbon fiber 5.0%. The electrolytic copper powder and short carbon fiber are subjected to high-energy ball milling, the ball milling ...

Embodiment 3

[0109] The high-temperature wear-resistant composite material prepared in Example 3 includes the following components in terms of mass percentage:

[0110] Electrolytic copper powder 77.5%, flake graphite powder 9.0%, short carbon fiber 2%, fine alumina powder 1.5%, coarse alumina powder 9.0%, silicon carbide powder 1.0%. The particle size of electrolytic copper powder is 50 μm, the particle size of flake graphite powder is 45 μm, the particle size of fine alumina powder is 1 μm, the particle size of coarse alumina powder is 80 μm, and the particle size of silicon carbide powder is 50 μm.

[0111] Firstly, the composite pre-alloyed powder I of short carbon fiber and copper powder is prepared, which includes the following components in terms of mass percentage: electrolytic copper powder 96%, short carbon fiber 4.0%. The electrolytic copper powder and short carbon fiber are subjected to high-energy ball milling, the ball milling speed is 250 rpm, and the ball milling time is 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com