Composite plate of intermetallic TiAl compound and Ti alloy and its production process

A technology of intermetallic compounds and composite plates, applied in chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of poor thermal workability of TiAl intermetallic compounds, achieve room temperature and high temperature mechanical properties improvement, thermal Improved processing performance and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

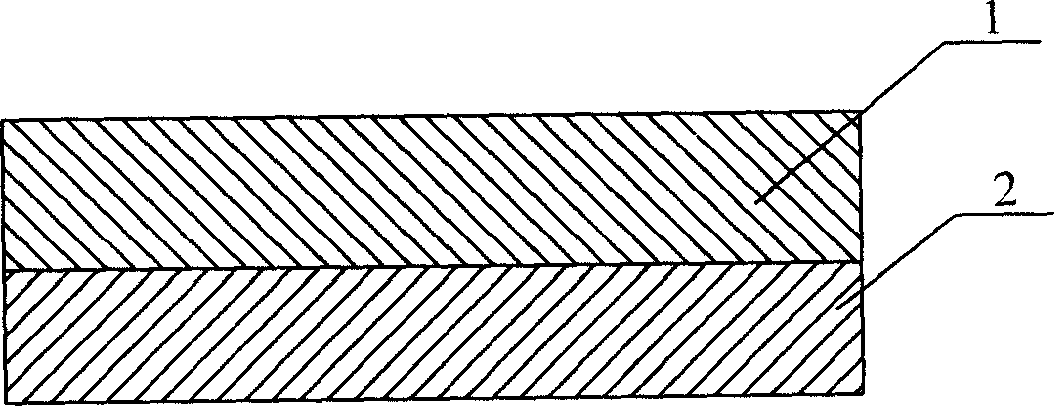

[0008] Specific implementation mode one: as figure 1 , The TiAl intermetallic compound-titanium alloy composite plate in this embodiment is composed of a plate 1 made of TiAl intermetallic compound and a plate 2 made of pure titanium or titanium alloy. According to the composition of the TiAl intermetallic compound, the Ti content can be changed in the range of 35at% to 65at%, and the Al content can be changed in the range of 35at% to 60at%. The TiAl intermetallic compound is added with Nb, Cr, Mn, V , Ni, W, Hf, Ta, Mo, Zr, Si, Y, La, Ce, C, B, O, N, TiC, TiB or TiB 2 TiAl-based alloys of one or several elements in which Nb, Cr, Mn, V, Ni, W, Hf, Ta, Mo, Zr, Si, Y, La, Ce, C, B, O, N, TiC, TiB or TiB 2 The addition of one or several elements in is less than 20 at.%.

specific Embodiment approach 2

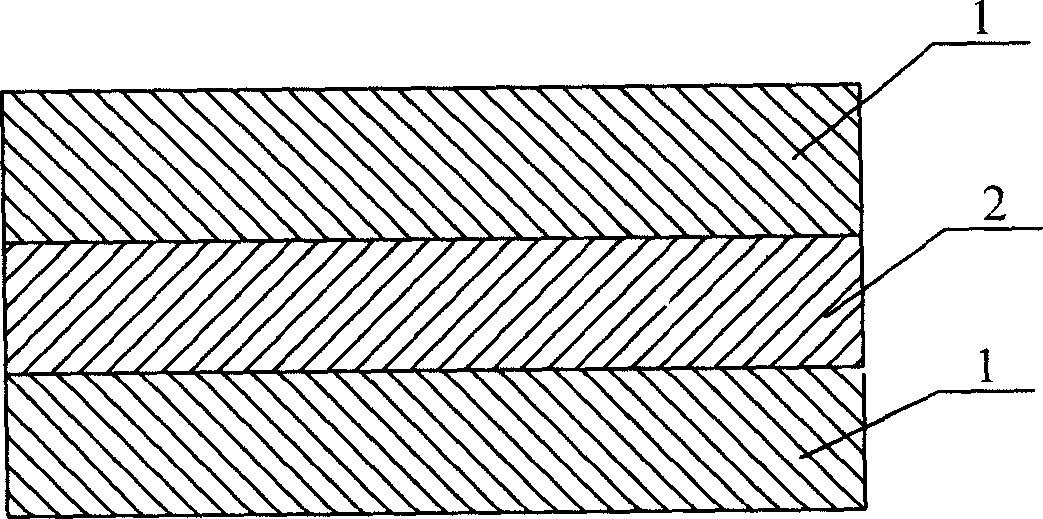

[0009] Specific embodiment two: this embodiment is processed according to the following method: in order to ensure that the combination between the TiAl intermetallic compound and the titanium alloy plate is firm, before rolling, the material is the plate or block of the TiAl intermetallic compound and the material is pure titanium. or titanium alloy plates or blocks are polished or polished respectively to ensure that the surface of the blocks to be compounded has a certain degree of smoothness; At least one layer of TiAl intermetallic compound-titanium alloy composite plate made of pure titanium or titanium alloy plate, the main process parameters of rolling are: temperature 600-1400°C, pass deformation 2-40%, total rolling deformation 5-95%. The bulk or other shapes of TiAl intermetallic compound materials prepared by various preparation methods in this embodiment can be used to prepare TiAl intermetallic compound-titanium alloy composite plates.

specific Embodiment approach 3

[0010] Specific Embodiment Three: In this embodiment, the preparation of Ti-43Al-9V-0.3Y alloy (a TiAl intermetallic compound)-Ti-6Al-4V alloy (a titanium alloy) composite plate is taken as an example (the sheath is directly bound) .

[0011] (1) Wrap the massive Ti-43Al-9V-0.3Y alloy with a size of 150mm in length, 100mm in width and 10mm in thickness in a Ti-6Al-4V alloy sleeve. -4 The welding wire is welded flat to form a cube shape, and the thickness of the sleeve is 5mm. The surface of the block Ti-43Al-9V-0.3Y alloy and the inner surface of the sleeve should be polished (sandpaper to 1000 mesh), so that the two The materials are firmly bonded after rolling;

[0012] (2) The wrapped whole is heated to 1100°C in a heat treatment furnace and kept warm for 1 hour;

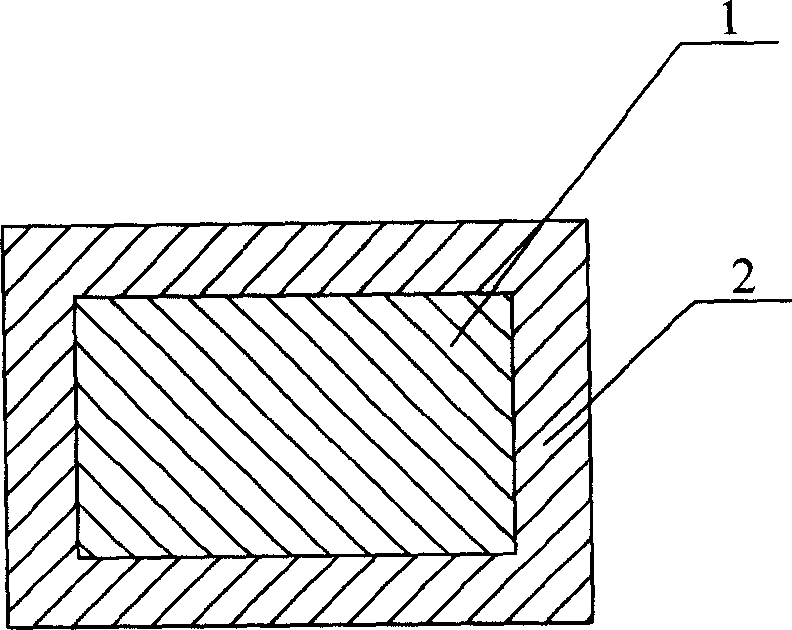

[0013] (3) The whole body is then hot-rolled on a rolling mill to form a composite plate that wraps Ti-6Al-4V alloy 2 on the outside and Ti-43Al-9V-0.3Y alloy 1 on the inside (such as figure 2 ).

[0014] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com