Concrete stirring equipment with internal cleaning function and operation method thereof

A mixing equipment and concrete technology, applied in the field of concrete mixing equipment with internal cleaning function, can solve the problems of high residual rate of the inner wall, insufficient mixing, difficult to clean, etc., to improve the cleaning effect, speed up the scrubbing efficiency, and no cleaning dead ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

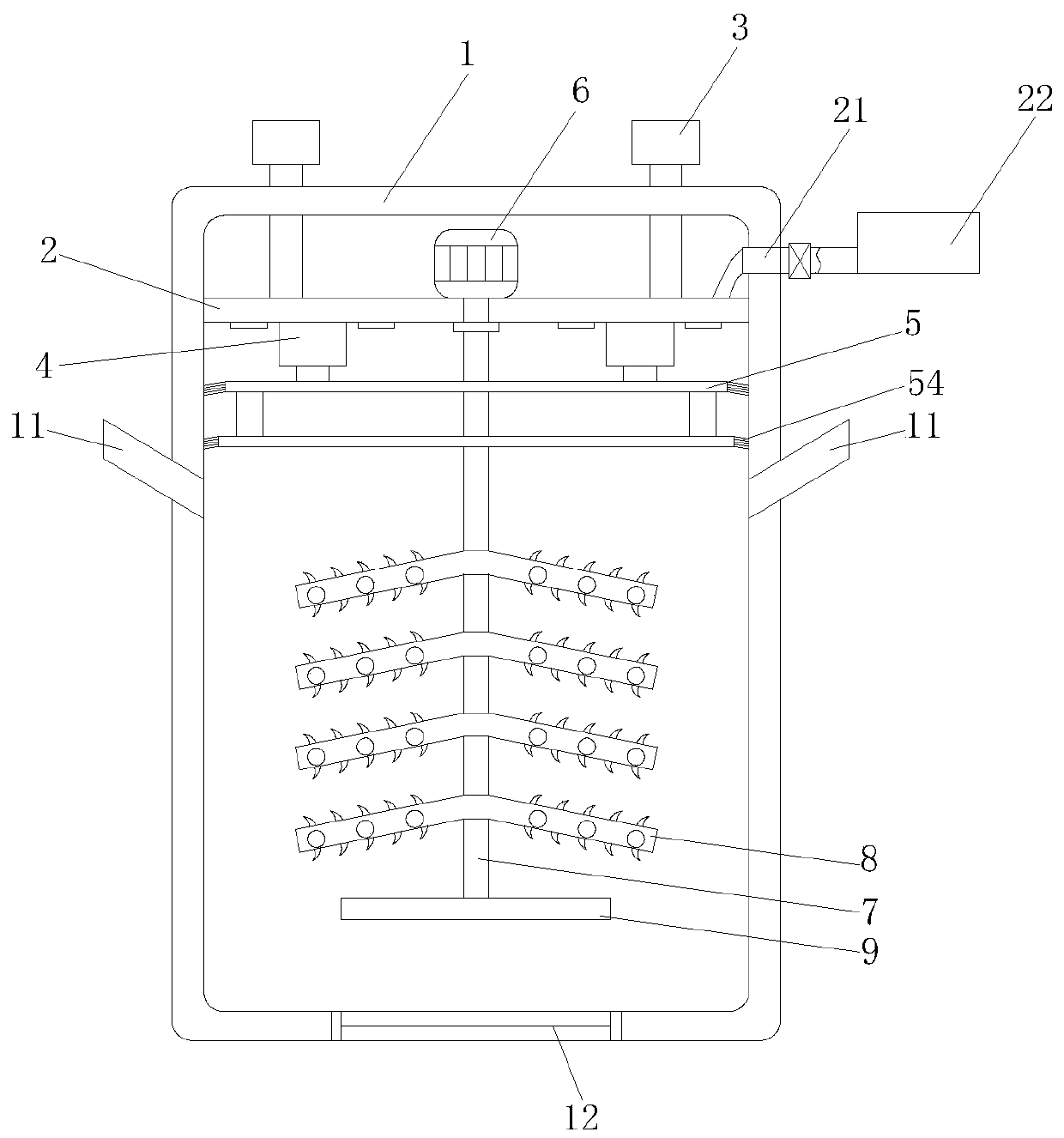

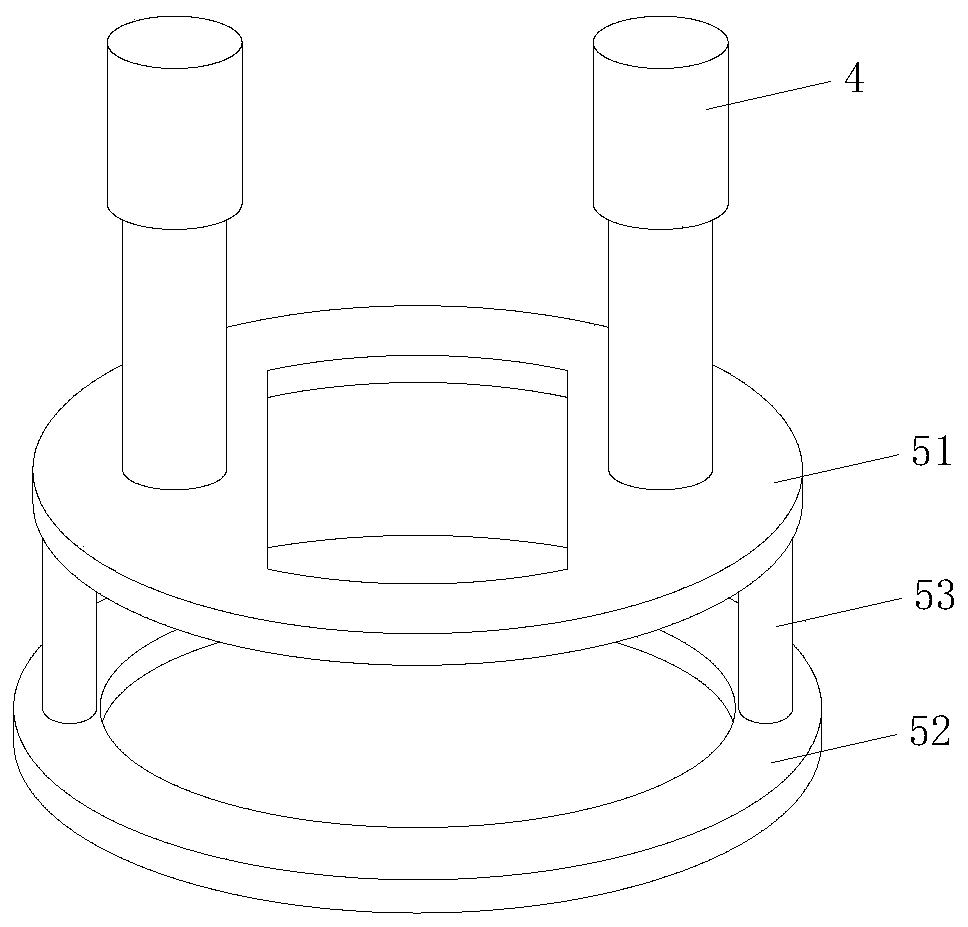

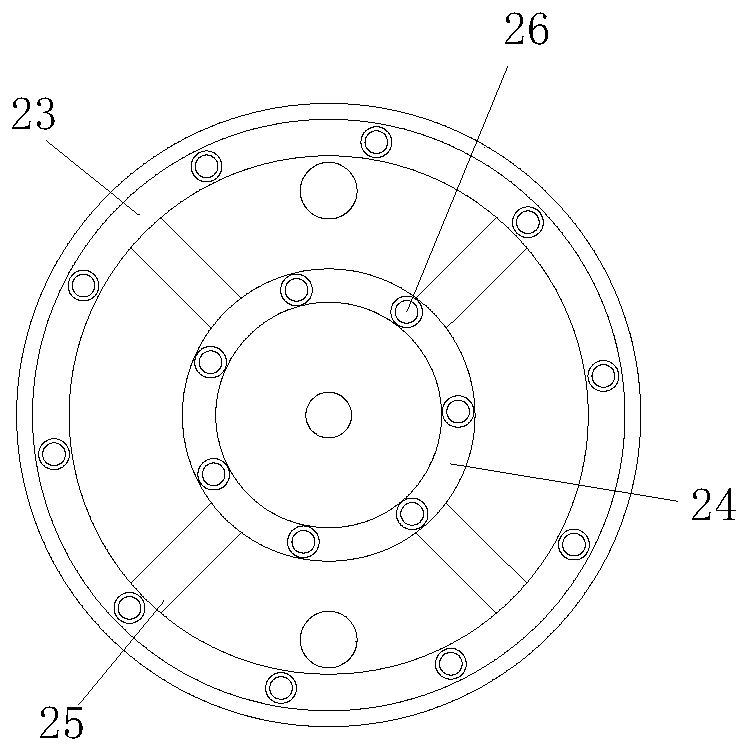

[0031] from Figure 1-4 It can be seen that a concrete mixing equipment with an internal cleaning function in this embodiment includes a box body 1, and a material inlet 11 is opened on both sides of the box body 1, and a material outlet 12 is opened at the bottom of the box body 1. Valves are respectively installed on the inner side of the feed port 11 and the discharge port 12, through which the state and flow rate of the feed port 11 and the discharge port 12 can be changed. A first hydraulic cylinder 3 is installed on the top of the box body. The output end of the first hydraulic cylinder 3 runs through the upper surface of the box body 1 and is fixedly connected with the deflector 2. The first hydraulic cylinder 3 drives the deflector 2 to move up and down, and the deflector 2 The upper surface of 2 is connected with a spray water pipe 21, and a booster pump is installed between the spray water pipe 21 and the water tank 22. The input end of the water pipe 21 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com