Disulfiram lipid microsphere preparation for injection for treating tumor and preparation method thereof

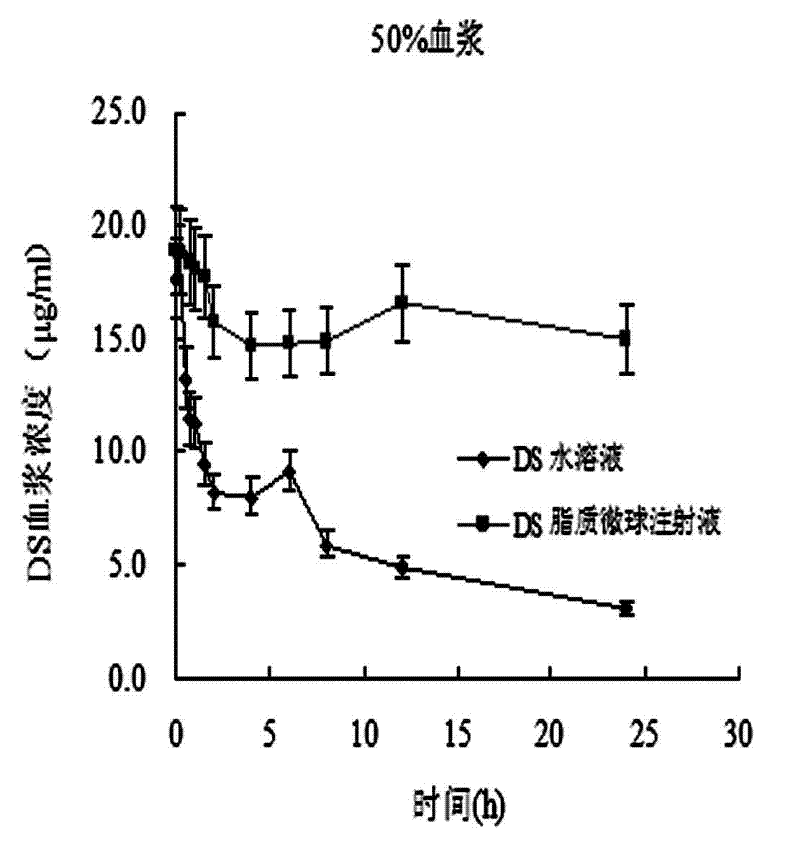

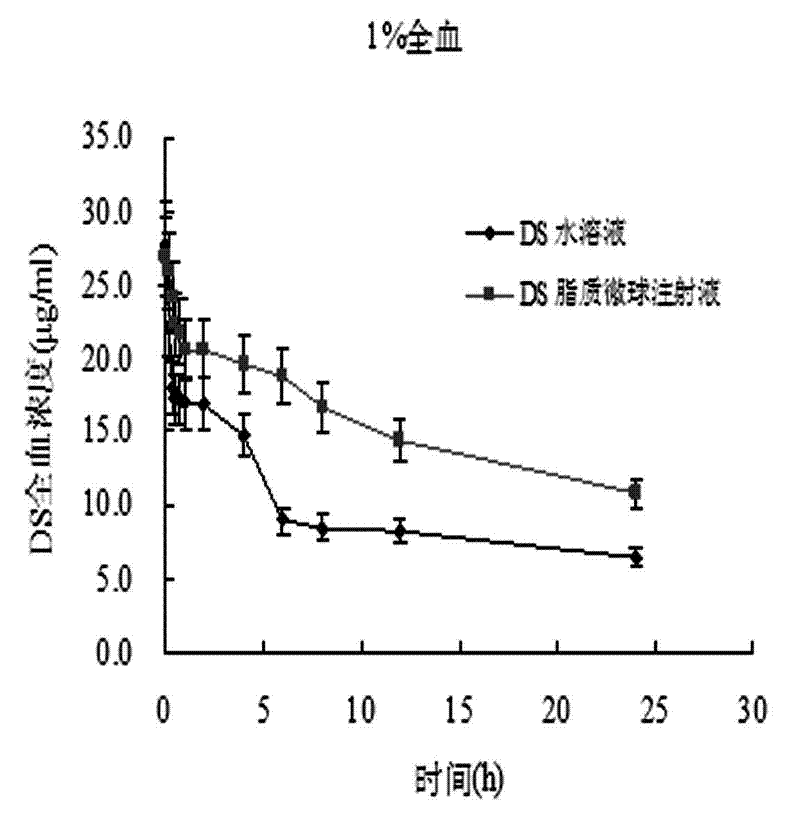

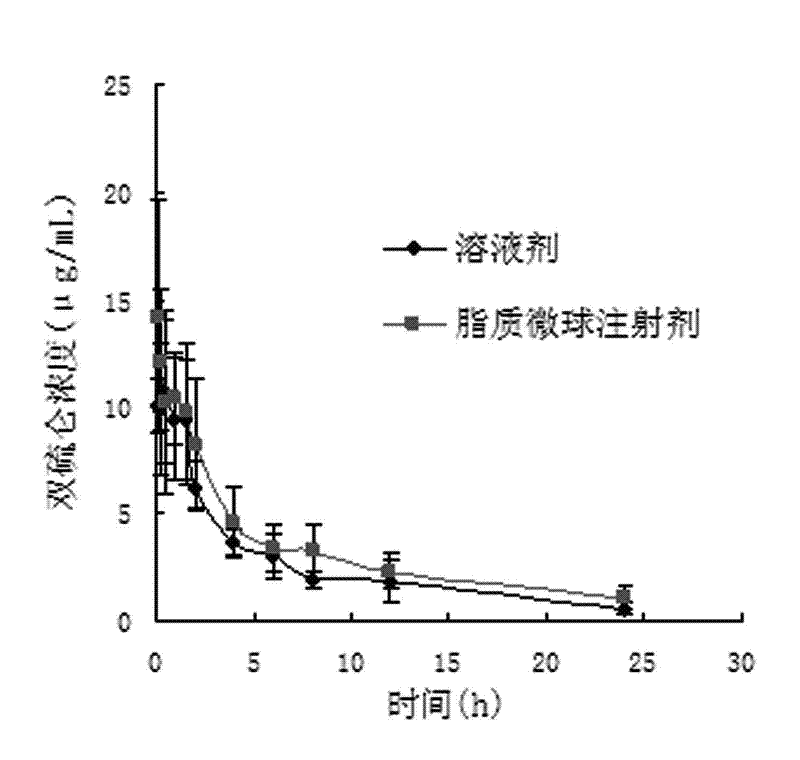

A technology for lipid disulfiram and injection, which is applied in the directions of antitumor drugs, inactive ingredients of oil/fat/wax, powder delivery, etc., can solve the problem of low blood concentration of disulfiram, and achieve sterilization stability Good, high drug loading, and the effect of improving drug bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The most preferred disulfiram lipid microsphere formulation of the present invention:

[0040] Take 20.0g of disulfiram, 100.0g of medium-chain triglycerides, 18.0g of lecithin, 5.0g of vitamin E, and 5.0g of polyethylene glycol phospholipids, heat to 70°C under nitrogen protection, and stir for about 10 minutes to make The various lipid compounds added are fully dissolved and dissolved evenly; take another 800ml of water for injection, add 22.5g of glycerin, 1.0g of sodium oleate and 5.0g of amino acid block copolymer, stir and dissolve, adjust the pH to 5.0-8.0, and dissolve evenly ;Under the condition of nitrogen protection, the oil solution containing the drug is added to the aqueous solution of glycerin and sodium oleate under shearing and stirring to make colostrum, and the total amount is adjusted to 1000ml, and the high-pressure homogenizer is homogenized 6-15 times , the homogenization pressure is about 80MPa, and the particle size ranges from 180nm to 250nm, f...

Embodiment 2

[0045] Disulfiram lipid microsphere formulation with the lowest disulfiram content

[0046] Take 1.0g of disulfiram, 100.0g of soybean oil, 18.0g of hydrogenated egg yolk lecithin, and 5.0g of vitamin E. Under nitrogen protection, heat to 70°C and stir for about 10 minutes to fully dissolve the various lipid compounds added. Dissolve evenly; take another 850ml of water for injection, add 22.5g of glycerin and 1.0g of sodium oleate, stir to dissolve, adjust the pH to 5.0-8.0, and dissolve evenly; Add glycerin and sodium oleate aqueous solution to make colostrum, and adjust the total amount to 1000ml with water for injection, homogenize 6-15 times with a high-pressure homogenizer, the homogenization pressure is about 80MPa, and the particle size ranges from 180nm-250nm , filtered, subpackaged, fed with nitrogen, sealed, 121 ° C rotary sterilization for 10 minutes, after passing the light inspection, packaged, and stored below 25 ° C.

[0047] The lecithin described in this embo...

Embodiment 3

[0049] Disulfiram lipid microsphere formulation with the highest disulfiram content

[0050] Take 40.0g of disulfiram, 150.0g of garlic oil, 24.0g of egg yolk lecithin, and 3.0g of vitamin E. Under nitrogen protection, heat to 70°C and stir for about 10 minutes to fully dissolve the various lipid compounds added. Uniformly; take another 800ml of water for injection, add 22.5g of glycerin and 1.0g of sodium oleate, stir to dissolve, adjust pH5.0-8.0, dissolve evenly; under the condition of nitrogen protection, add the oil solution containing the drug under shearing and stirring In the aqueous solution of glycerin and sodium oleate, colostrum is made, and the total amount is adjusted to 1000ml with water for injection, homogenized by a high-pressure homogenizer for 6-15 times, the homogenization pressure is about 80MPa, and the particle size ranges from 180nm to 250nm. Filter, sub-package, inject nitrogen, seal, 121 ℃ rotation sterilization for 10 minutes, after passing the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com