Pipeline outer-wall reciprocating cleaning device

A cleaning device and technology for the outer wall of the pipeline, which is applied in the field of reciprocating cleaning devices for the outer wall of the pipeline, can solve the problems of low cleaning efficiency, high working intensity, and poor cleaning effect, achieve good cleaning effect, improve efficiency and quality, and improve scrubbing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

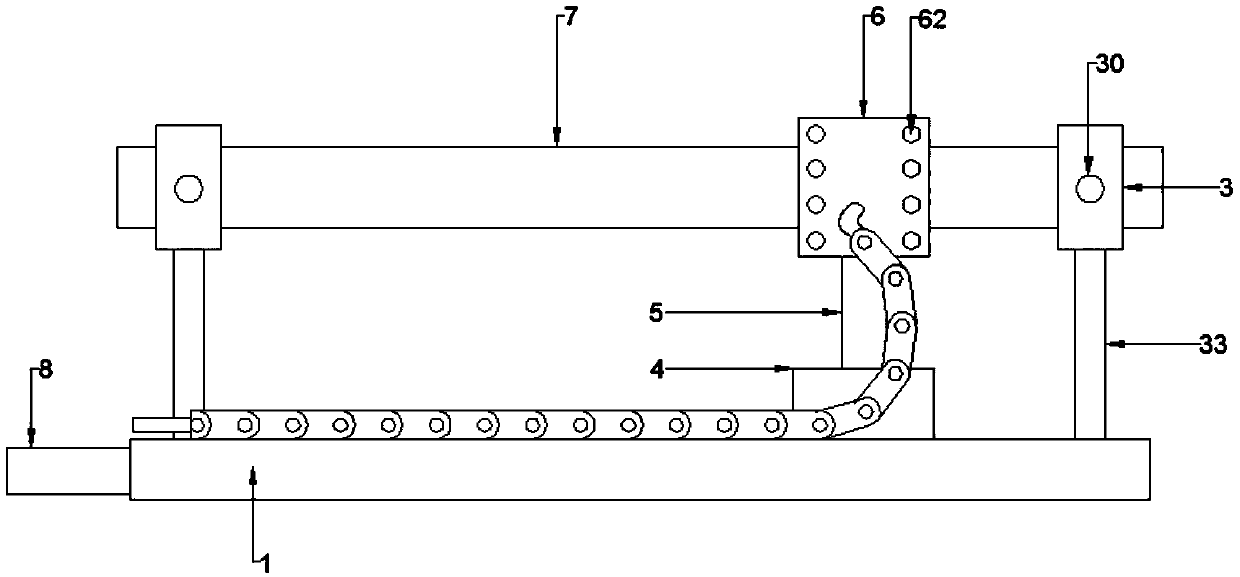

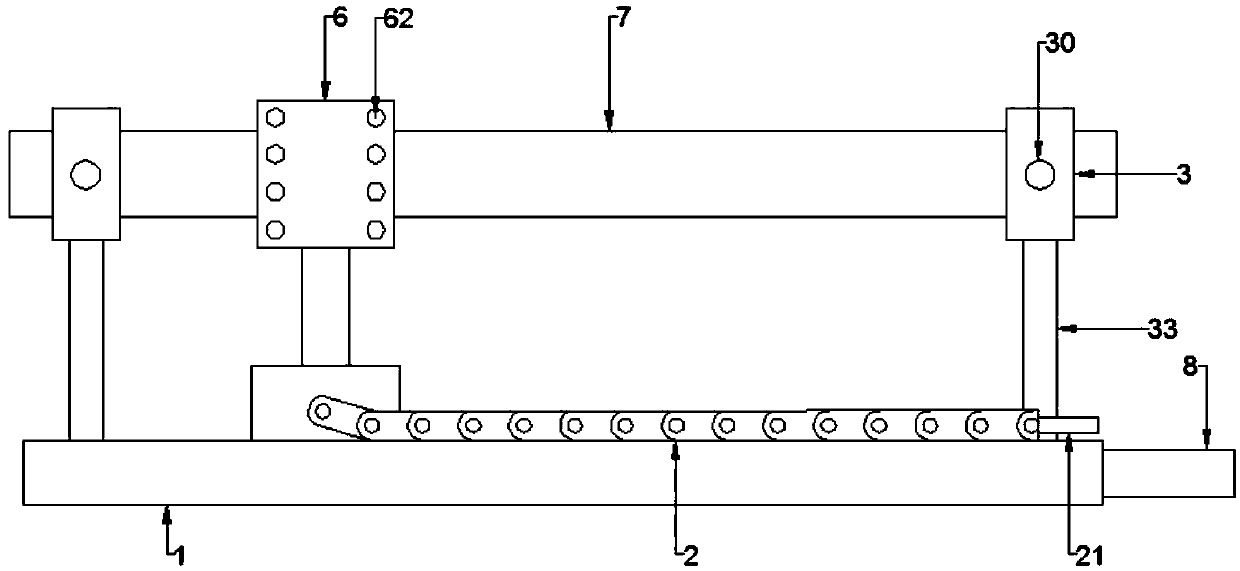

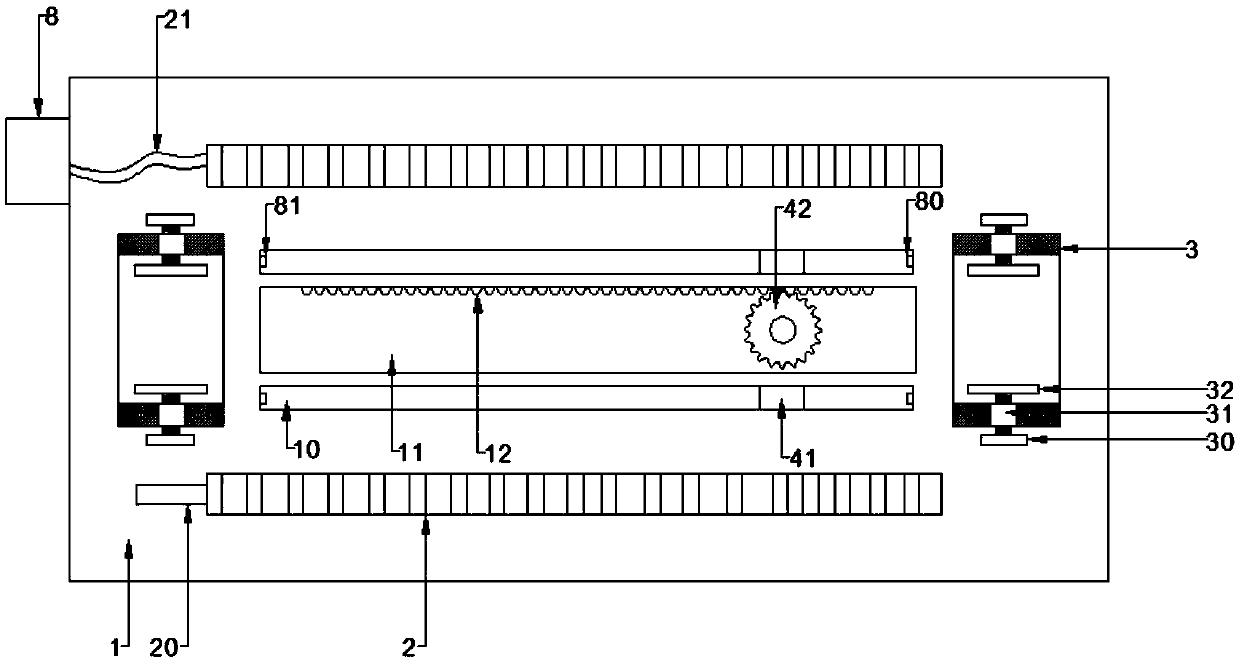

[0034] see Figure 1-8 , in an embodiment of the present invention, a reciprocating cleaning device for the outer wall of a pipeline includes a track bottom plate 1, a crawler box 2, a support ring 3, a drive box 4, a support rod 5, a cleaning sleeve 6, and a control box 8. The track bottom plate 1 Two crawler boxes 2 are arranged on the front, rear and both sides of the top of the track box 2, and high-pressure water pipes 20 and power lines 21 are respectively installed in the track boxes 2, and 33 are fixed on the left and right sides of the top surface of the track bottom plate 1, and the 33 is fixed The supporting rings 3 are connected to the supporting rings 3, and the pipes 7 are arranged between the supporting rings 3. The cleaning sleeve 6 is sleeved on the pipes 7. The cleaning sleeve 6 is provided with a cleaning structure. The cleaning sleeve 6 The front side is connected to the high-pressure water pipe 20 through the crawler box 2. The bottom of the cleaning sleev...

Embodiment 2

[0049] The difference from Embodiment 1 is that a plurality of support screw holes 31 are provided on the side wall of the support ring 3 , and the inner thread of the support screw holes 31 is passed through the support adjustment bolt 30 , and the inner side of the support adjustment bolt 30 The support plate 32 is fixed at the end;

[0050] The setting of the 32 can ensure that the two ends of various pipes 7 can be stably fixed, instead of only stabilizing the 7 through the sheathing of the 6, so that the device can adapt to 7 of various sizes, improving the range of adaptation and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com