Ascent-free automatic scrubbing device for insulator

A technology of insulators and scrubbers, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of general cleaning effect, high cost, and cleaning dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

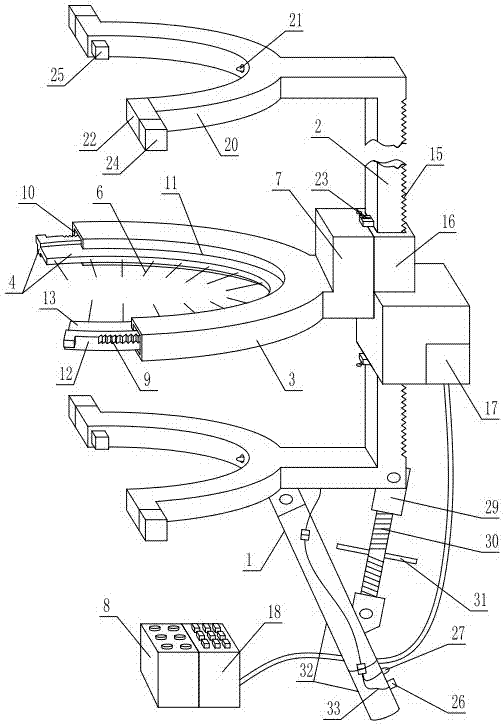

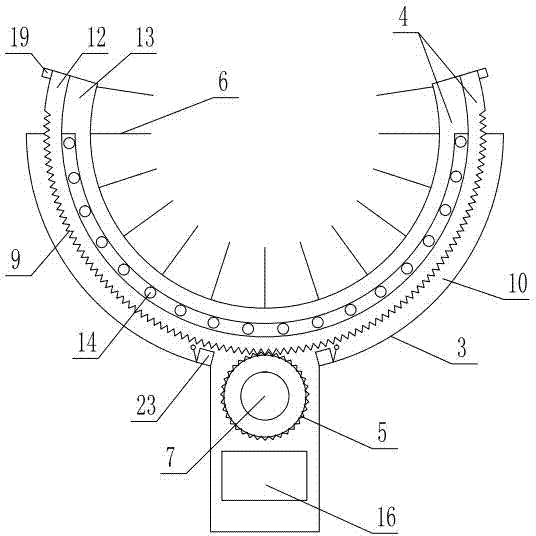

[0033] Specific embodiment one, such as figure 1 , figure 2 As shown, the free-climbing insulator automatic scrubber includes a bracket 2 installed on the upper end of the support rod 1, and the bracket 2 is equipped with related components such as a scrubbing motor 7 and a brush 6 that can scrub the insulator, so the automatic scrubbing of the free-climbing insulator The insulator can clean the insulators on the ground without climbing up. Support 2 is the main structure of the automatic scrubber for free-climbing insulators, and all parts related to scrubbing are directly or indirectly installed on the support 2. Locking mechanisms respectively corresponding to the two ends of the insulator are installed at both ends of the bracket 2, and the main function of the locking mechanism is to automatically lock and unlock the ends of the insulator under the control of the operator. When the two ends of the bracket 2 are locked on the upper and lower ends of the insulator by the...

specific Embodiment 2

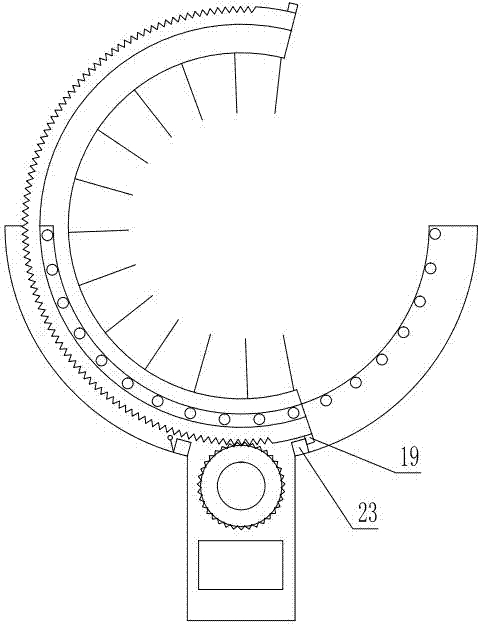

[0045] Specific embodiment two, such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the locking mechanism includes a "U"-shaped half-ring 20 fixed at both ends of the bracket and whose inner wall matches the outer wall of the end of the insulator. The two ends of the ring are equipped with slides with mouths opposite to each other. Electromagnet 24 is installed at the bottom of the slide cavity, and a slide bar is installed on the slide cavity mouth. The spring that bar elasticity is released, is provided with the opening switch 26 of control electromagnet power supply on-off on the support bar, and the half-ring inner wall middle part is provided with the normally closed self-resetting switch 21 that is connected in series in the electromagnet power supply circuit, is also installed on the support bar The normally open end button 28 connected in parallel with the self-resetting switch. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com