Dinner plate cleaning machine

A washing machine and dish plate technology, which is applied in the direction of tableware washing machine/rinsing machine, cleaning equipment, household cleaning device, etc., can solve the problems of heavy labor and low washing efficiency, and achieve the effect of fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

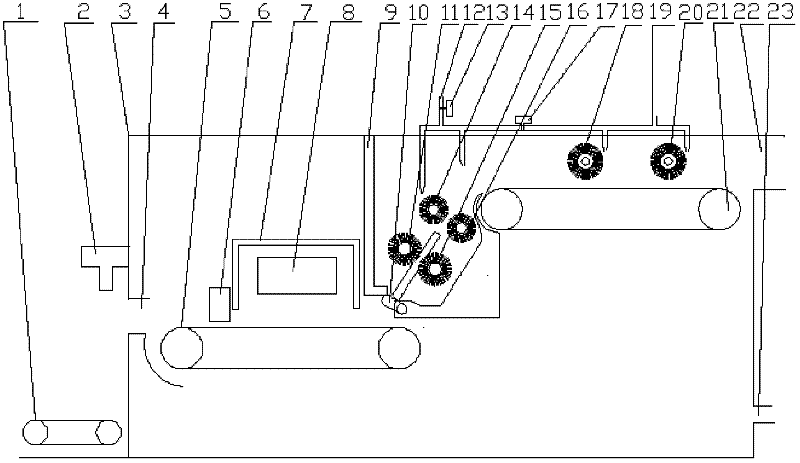

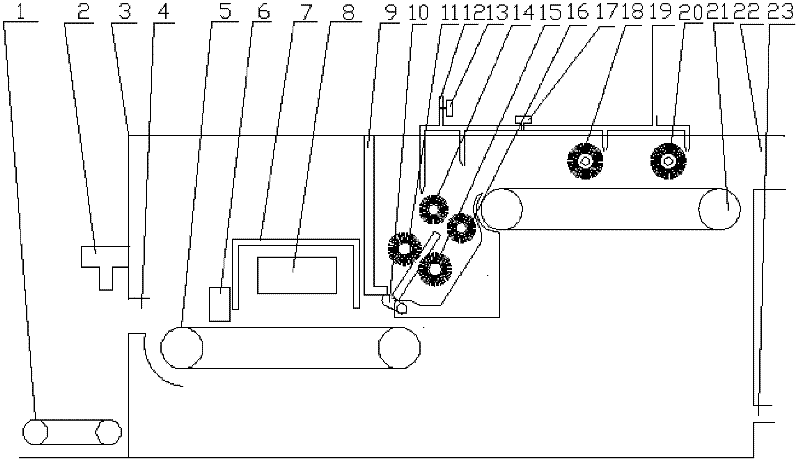

[0015] A dish washing machine, figure 1 Middle: 1. Pulley I, 2. Infrared counter, 3. Housing, 4. Outlet port, 5. Sprocket, 6. Block I, 7. Disinfection cover, 8. High temperature heater, 9. Partition plate, 10. Block II, 11. Cylindrical brush wheel I, 12. Water inlet, 13. Electromagnetic switch I, 14. Cylindrical brush wheel II, 15. Cylindrical brush wheel III, 16. Cylindrical brush wheel IV, 17 , Electromagnetic switch II, 18, cylindrical brush wheel V, 19, washing liquid inlet, 20, cylindrical brush wheel VI, 21, belt pulley II, 22, inlet plate, 23, water outlet. The housing 3 is provided with a cylindrical brush wheel I11, a cylindrical brush wheel II14, a cylindrical brush wheel III15, and a cylindrical brush wheel IV16. It is characterized in that the cylindrical brush wheel I11, the cylindrical brush wheel II14, and the cylindrical brush wheel Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com