Anti-collision barrel cleaning equipment for bridge construction

A technology for bridge construction and bucket cleaning, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient use, poor cleaning effect, complicated operation of cleaning equipment, etc., and achieve high brushing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

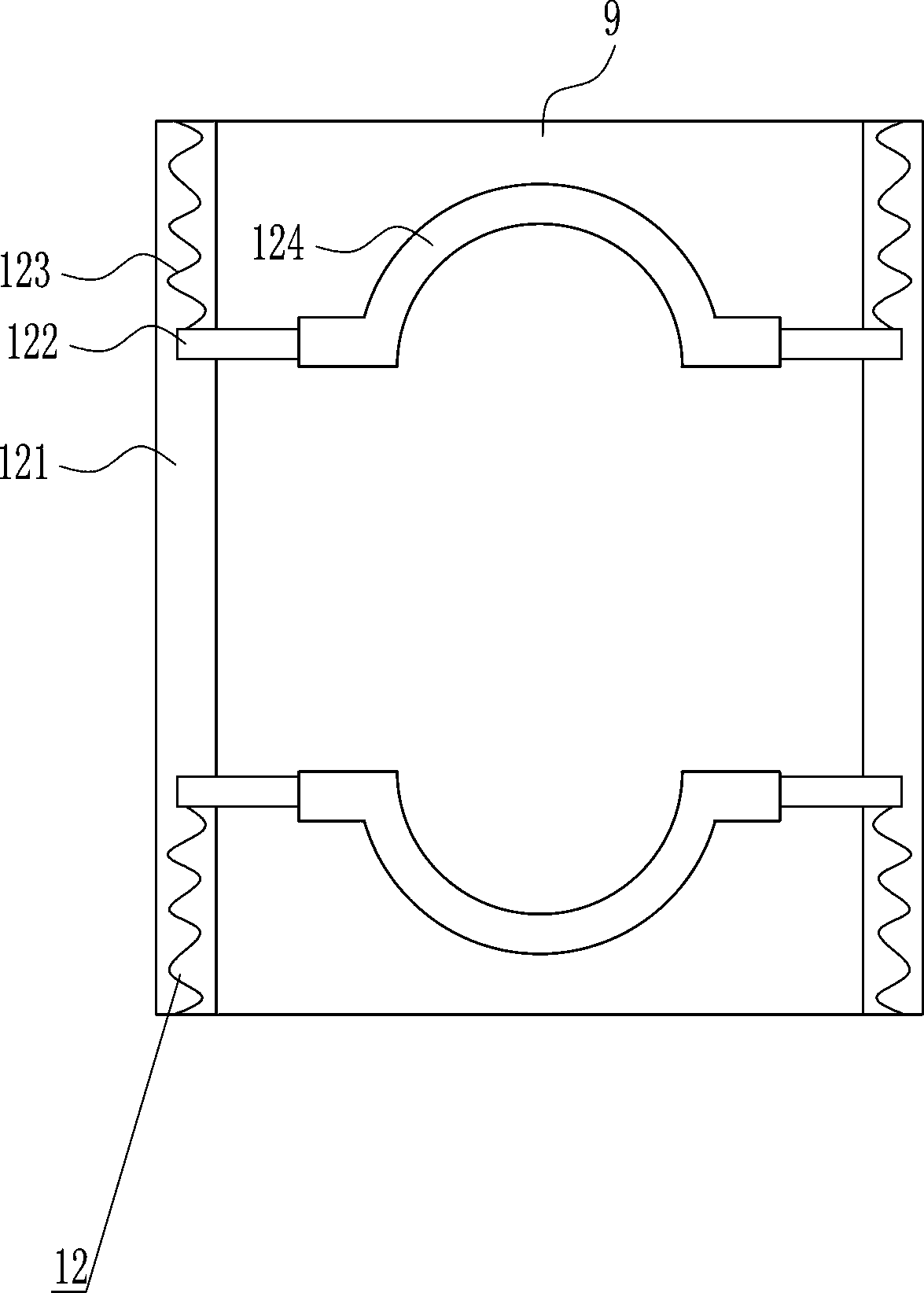

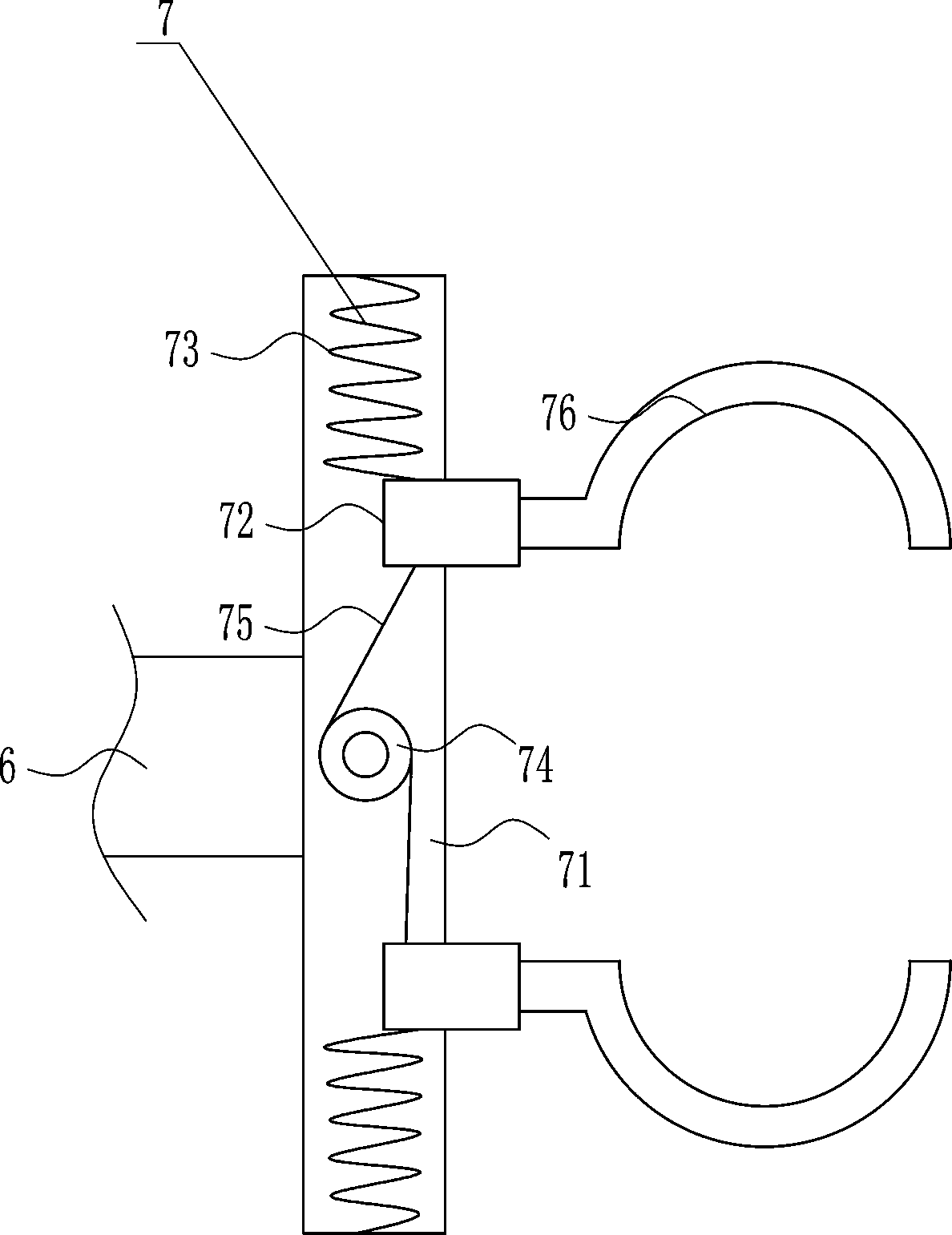

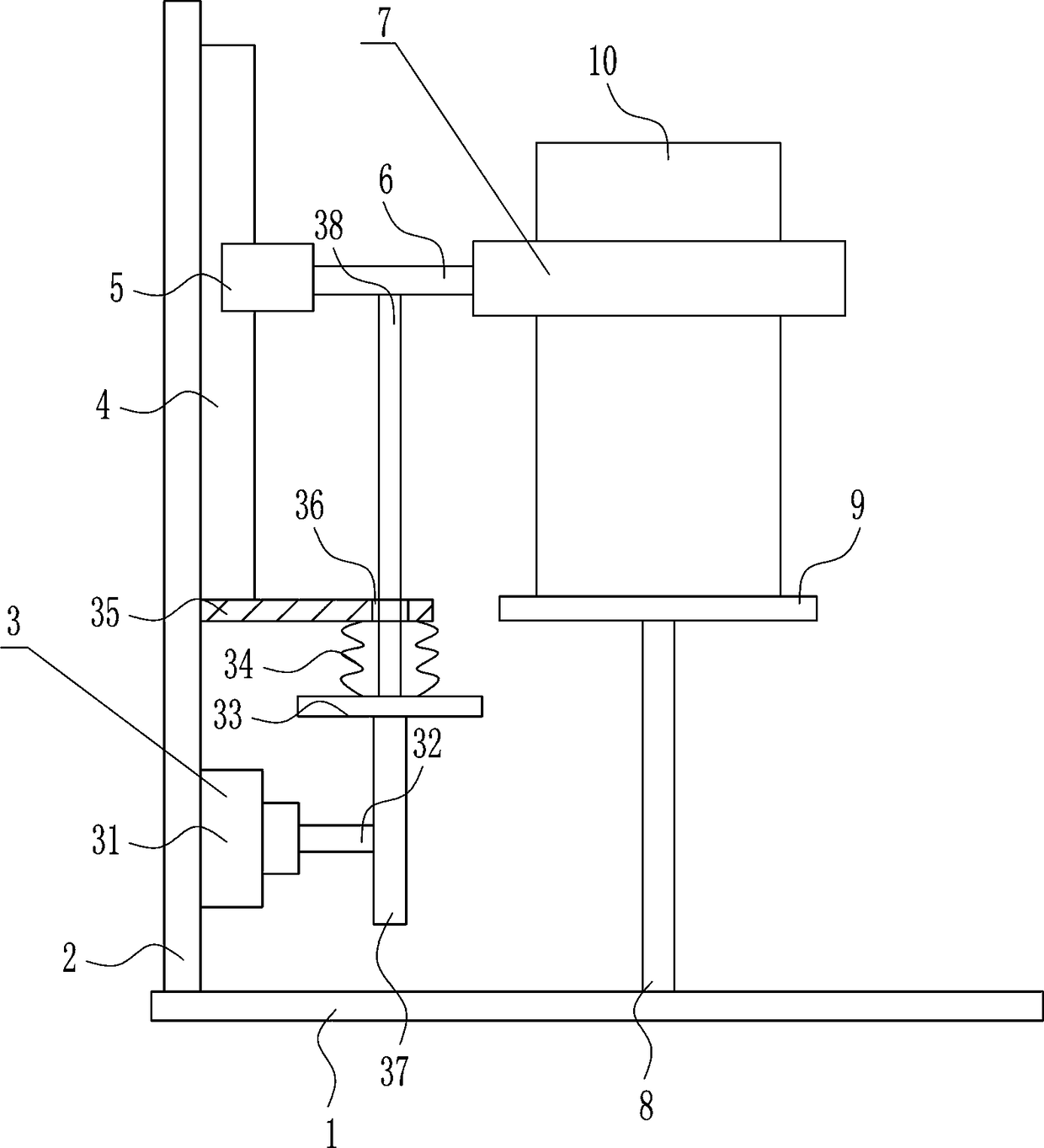

[0037] A kind of anti-collision barrel cleaning equipment for bridge construction, such as Figure 1-6 As shown, it includes a bottom plate 1, a left bracket 2, a driving mechanism 3, a first slide rail 4, a first slider 5, a cross bar 6, a cleaning mechanism 7, a support rod 8, and a placement table 9. The top left side of the bottom plate 1 is provided with Left support 2, left support 2 right lower part is provided with driving mechanism 3, and left support 2 right upper part is provided with first slide rail 4, and first slide rail 4 is provided with first slide block 5, and first slide block 5 right Side is provided with cross bar 6, and cross bar 6 right end is connected with cleaning mechanism 7, is provided with support rod 8 in the middle of bottom plate 1 top, and support rod 8 top is connected with placement platform 9, and placement platform 9 top is provided with anti-collision bucket 10.

Embodiment 2

[0039] A kind of anti-collision barrel cleaning equipment for bridge construction, such as Figure 1-6As shown, it includes a bottom plate 1, a left bracket 2, a driving mechanism 3, a first slide rail 4, a first slider 5, a cross bar 6, a cleaning mechanism 7, a support rod 8, and a placement table 9. The top left side of the bottom plate 1 is provided with Left support 2, left support 2 right lower part is provided with driving mechanism 3, and left support 2 right upper part is provided with first slide rail 4, and first slide rail 4 is provided with first slide block 5, and first slide block 5 right Side is provided with cross bar 6, and cross bar 6 right end is connected with cleaning mechanism 7, is provided with support rod 8 in the middle of bottom plate 1 top, and support rod 8 top is connected with placement platform 9, and placement platform 9 top is provided with anti-collision bucket 10.

[0040] Drive mechanism 3 comprises motor 31, rotating shaft 32, pressing pl...

Embodiment 3

[0042] A kind of anti-collision barrel cleaning equipment for bridge construction, such as Figure 1-6 As shown, it includes a bottom plate 1, a left bracket 2, a driving mechanism 3, a first slide rail 4, a first slider 5, a cross bar 6, a cleaning mechanism 7, a support rod 8, and a placement table 9. The top left side of the bottom plate 1 is provided with Left support 2, left support 2 right lower part is provided with driving mechanism 3, and left support 2 right upper part is provided with first slide rail 4, and first slide rail 4 is provided with first slide block 5, and first slide block 5 right Side is provided with cross bar 6, and cross bar 6 right end is connected with cleaning mechanism 7, is provided with support rod 8 in the middle of bottom plate 1 top, and support rod 8 top is connected with placement platform 9, and placement platform 9 top is provided with anti-collision bucket 10.

[0043] Drive mechanism 3 comprises motor 31, rotating shaft 32, pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com