Silicon wafer de-gluing machine and control method thereof

A technology for degumming machines and silicon wafers, which is applied in the fields of chemical instruments and methods, semiconductor/solid-state device manufacturing, water/sludge/sewage treatment, etc. It can solve the problems of poor spraying effect and low utilization rate of spraying water, and achieve The effects of saving water, improving the surface quality of silicon wafers, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

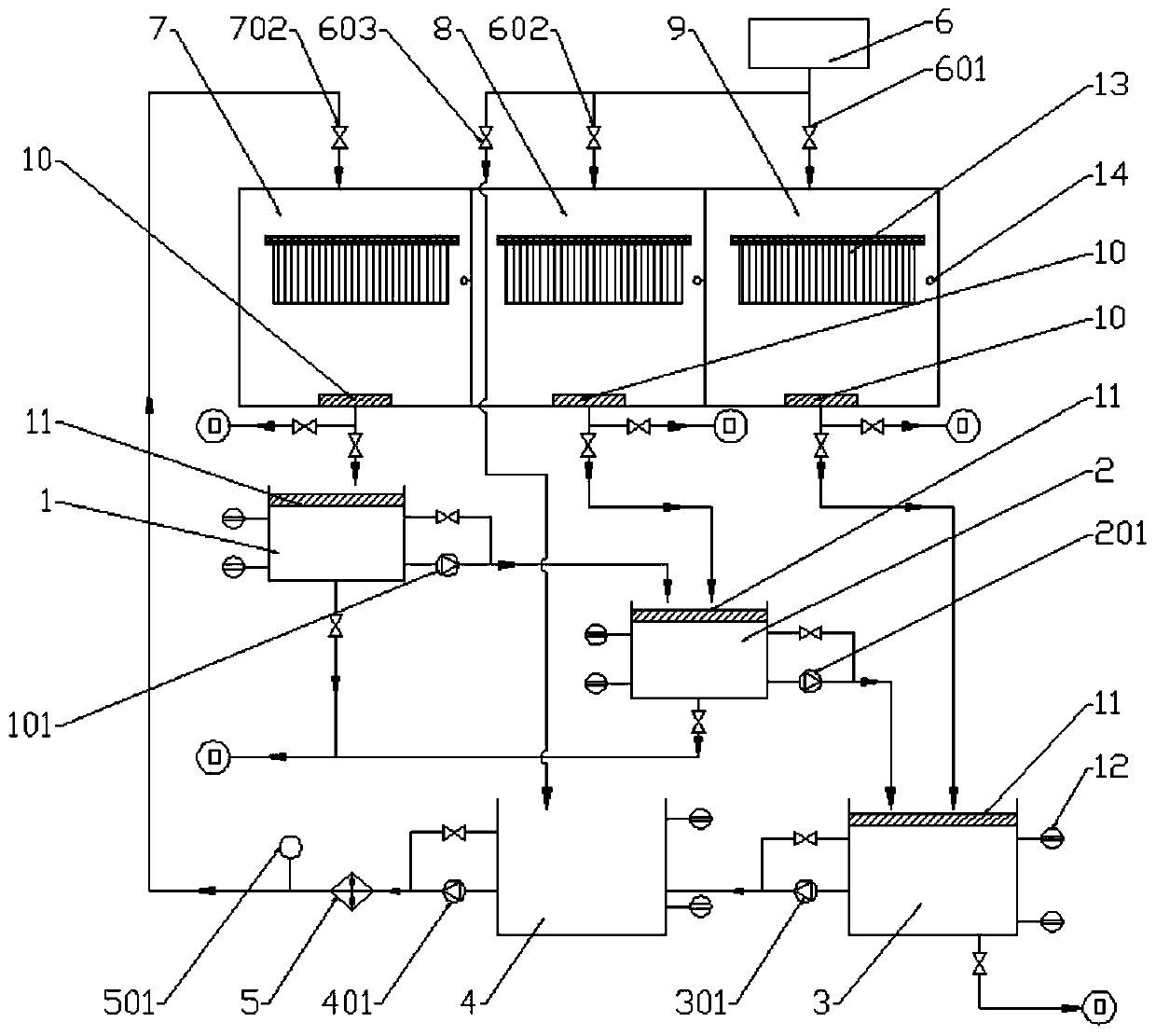

[0053] A silicon wafer degumming machine, such as figure 1 As shown, it includes the first groove 7, the second groove 8 and the third groove 9 used for spraying silicon wafers, and the first groove 7, the second groove 8 and the third groove 9 are arranged independently in sequence, and also includes the primary filter box 1, The secondary filter box 2, the tertiary filter box 3, the water storage tank 4, the heater 5, the pure water source 6 and the controller.

[0054]Wherein, the primary filter box 1 communicates with the outlet of a tank 7 through a water pipe, and is used for recovering the waste water discharged from the tank 7 . The input port of the secondary filter box 2 communicates with the output port of the primary filter box 1 and the drain of the second tank 8 through water pipes, and the secondary filter box 2 is used to filter the water discharged from the primary filter box 1 and recover the water from the secondary filter box 1. Wastewater discharged from ...

Embodiment 2

[0078] Such as Figure 5 As shown, compared with Embodiment 1, the biggest difference of this embodiment is that the waste water sprayed from the second tank 8 is filtered by the first filter screen 10 and discharged into the third stage together with the waste water sprayed from the third tank 9 Recycling and filtering are carried out in the filter box 3 , and then enter the water storage tank 4 after being filtered by the second filter screen 11 arranged in the three-stage filter screen 3 . That is to say, the secondary filter box 2 only filters the water filtered from the primary filter box 1, and the water filtered by the secondary filter box 2 enters the tertiary filter box 3 together with the waste water discharged from the second tank 8 and the third tank 9 filter in. The setting of this structure can also realize the recycling of spray water, with a high utilization rate, and realize the purpose of saving water to the greatest extent. 7 Spray use requirements, saving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com