Seepage-proof material containing locust bean gum and method for planting agave sisalana in saline-alkali soil by using same

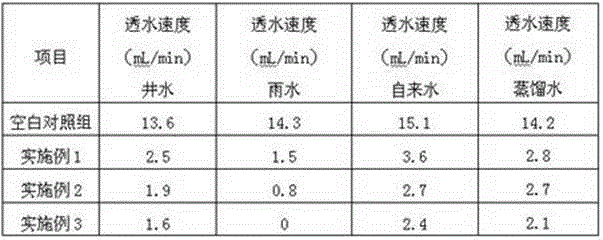

An anti-seepage material, locust bean gum technology, applied in the field of anti-seepage materials, can solve the problems of high impurity content of sisal and low strength of sisal bundle fibers, etc., and achieve the improvement of sisal leaf length, excellent water retention and water saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

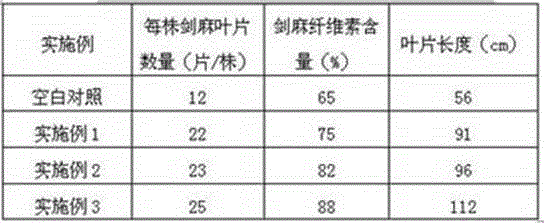

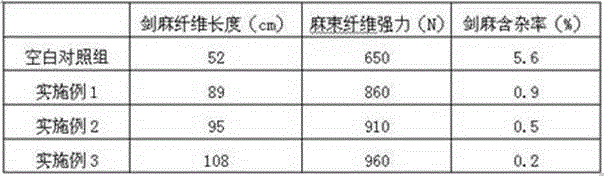

Examples

Embodiment 1

[0028] Embodiment 1 An anti-seepage material containing locust bean gum comprises the following raw materials in parts by weight:

[0029] 5 parts of gypsum powder, 6 parts of locust bean gum, 2 parts of tea polyphenols, 2 parts of chelated iron fertilizer, 1 part of bentonite, 2 parts of biological fertilizer, 10 parts of pig bone collagen, 1 part of pottery powder, hydroxypropyl starch 1.5 parts ether, 1 part neem extract;

[0030] The locust bean gum has a loss on drying of 6-8%, a total ash content of 0.2-0.4%, a protein content of 8-10%, and a mesh size of 135-165;

[0031] The tea polyphenols have a tea polyphenol content of 85-95%, a moisture content of 0.7-1.2%, and a pH value of 3.8-4.2;

[0032] The chelated iron fertilizer has a chelated iron content of 95-97%, an iron content of 15-17%, and a pH value of 5.2-5.5;

[0033] The bentonite is calcium-based bentonite with a silica content of 72-75%, an alumina content of 15-17.5%, and an apparent viscosity of 45-55% (...

Embodiment 2

[0037] Embodiment 2 A kind of anti-seepage material containing locust bean gum, including each raw material described in embodiment 1, only changing the ratio of raw materials, changing to:

[0038] 6 parts of gypsum powder, 8 parts of locust bean gum, 3 parts of tea polyphenols, 3 parts of chelated iron fertilizer, 2 parts of bentonite, 3 parts of biological fertilizer, 11 parts of pig bone collagen, 2 parts of pottery powder, hydroxypropyl starch 1.8 parts of ether, 1 part of neem extract.

Embodiment 3

[0039] Embodiment 3 A kind of anti-seepage material containing locust bean gum, comprises each raw material described in embodiment 1, only changes raw material ratio, changes to:

[0040] 7 parts of gypsum powder, 10 parts of locust bean gum, 4 parts of tea polyphenols, 4 parts of chelated iron fertilizer, 3 parts of bentonite, 4 parts of biological fertilizer, 12 parts of pig bone collagen, 3 parts of pottery powder, hydroxypropyl starch 2 parts ether, 2 parts neem extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com