Novel boiler

A boiler, a new type of technology, used in lighting and heating equipment, fluid heaters, water heaters, etc., can solve problems such as shortening service life, endangering safe operation, and corrosion under boiler scale, and achieves easy cleaning, convenient collection, and savings. The effect of using water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

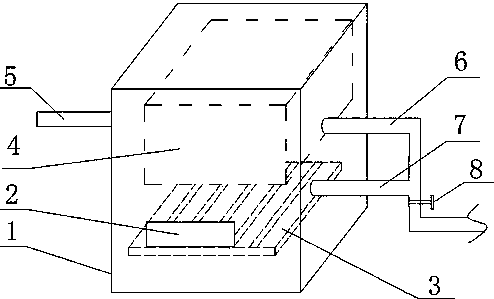

[0009] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0010] A new type of boiler, comprising a boiler body 1, characterized in that: a water tank 4 is provided above the interior of the boiler body 1, and a fuel filling port 2 is provided at the bottom of the boiler body 1; the interior of the boiler body 1 is connected to A fire grate 3 is provided below the corresponding part of the fuel filling port 2; a water inlet pipe 5 is provided on one side of the water tank 4, and a water outlet pipe 6 is provided on the other side of the water tank 4, and the water outlet pipe 6 corresponds to the fire grate 3. Ash flushing and return pipe 7 is provided.

[0011] Specifically, a control valve 8 is provided at the connection between the outlet pipe 6 and the ash flushing return pipe 7 , and the control valve 8 can control water flow into the ash flushing return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com