Roller spray quenching equipment

A roll and equipment technology, applied in the field of roll heat treatment auxiliary equipment, can solve the problems of unable to adjust the roll body line speed, not recycle water, waste water resources, etc., achieve safe and comfortable working conditions, reasonable structure, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments do not constitute any limitation to the present invention.

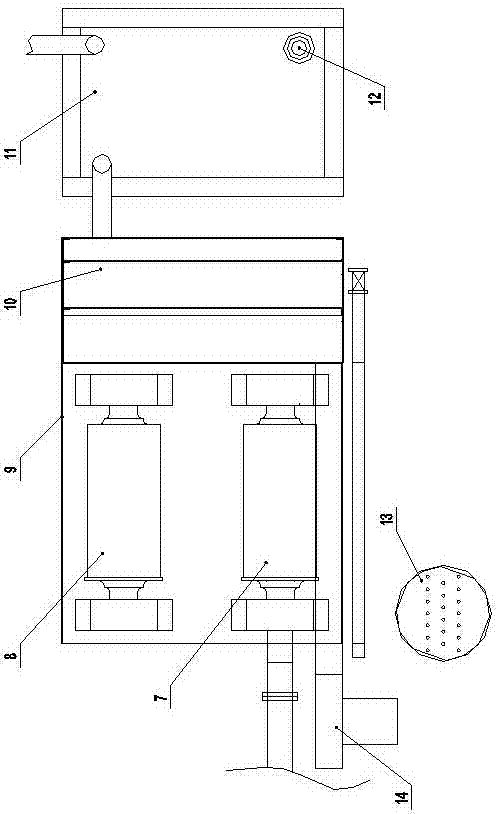

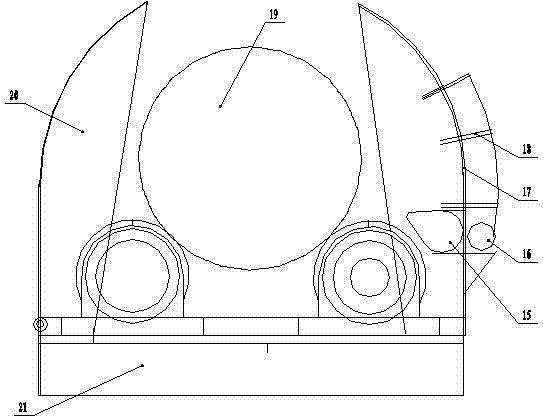

[0021] The roll spray quenching equipment given in this embodiment is mainly composed of a transmission system, a support system, a water supply system, and an air supply system.

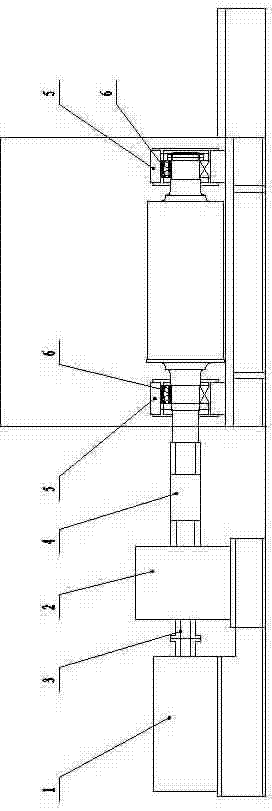

[0022] see figure 1 , figure 2 , the transmission system includes a motor 1, a reducer 2, a coupling 3, a universal joint 4, a driving tugboat 7, and a driven tugboat 8, the motor 1 adopts a frequency conversion motor, and the motor 1 is connected to the reducer 2 through a coupling 3, The low-speed shaft of the reducer 2 is connected to the tugboat shaft of the active tugboat 7 through the universal joint 4; the reducer 2 with a certain speed ratio is selected to convert the speed of the motor 1 to an appropriate number of revolutions, and then the low-speed output of the reducer 2 , so that the driving tugboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com