Direct mass balancing and coordinating control system of direct current boiler unit

A technology for coordinated control systems and unit units, applied to electric controllers, controllers with specific characteristics, mechanical equipment, etc., can solve problems such as limiting the adaptability of units to variable loads, high operating parameters, and not giving a complete control plan , to achieve the effect of improving the dynamic response characteristics and parameter stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Attached below Figure 1~3 Examples of the present invention will be described in detail, but the scope of protection of the present invention is not limited to the following examples.

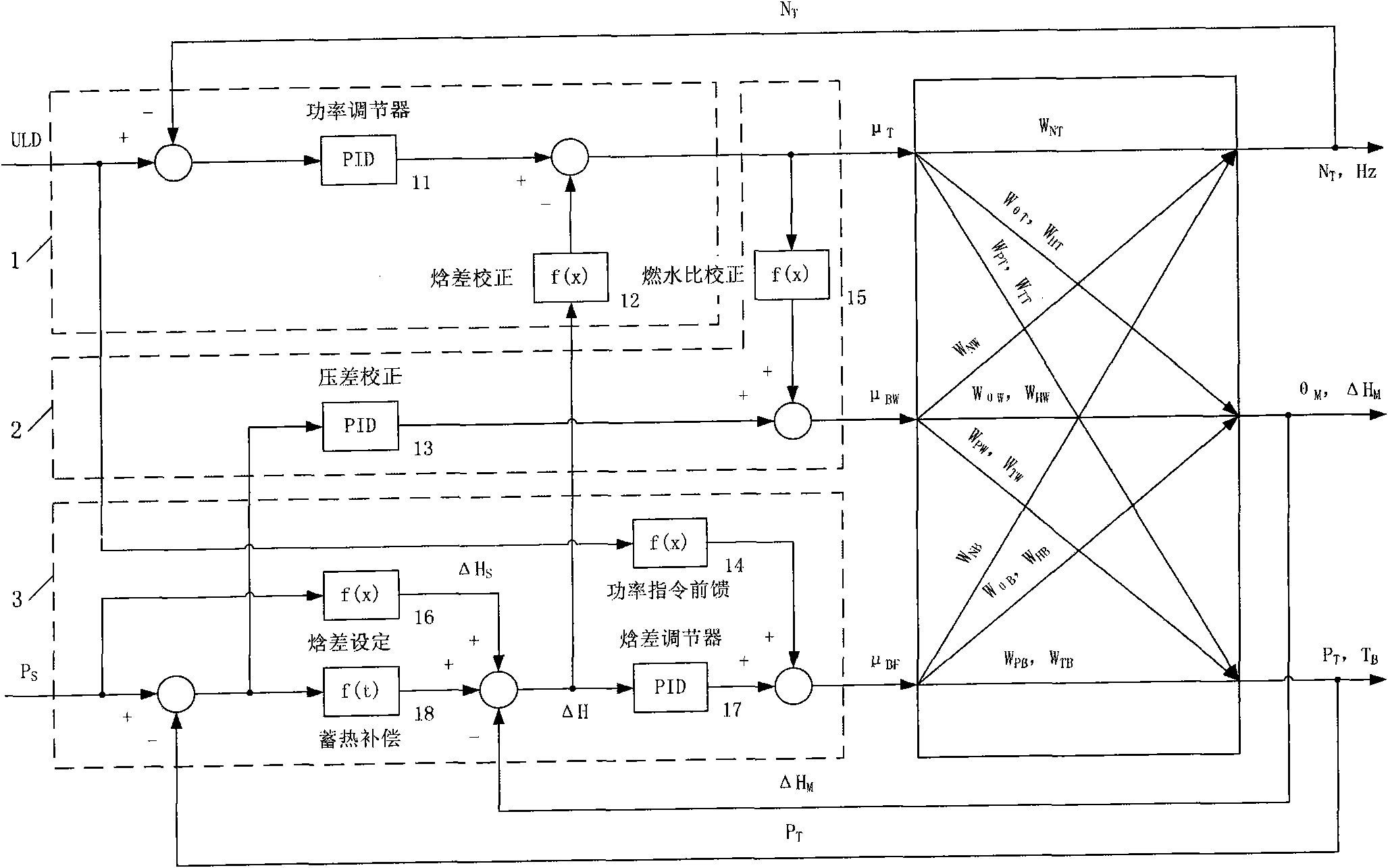

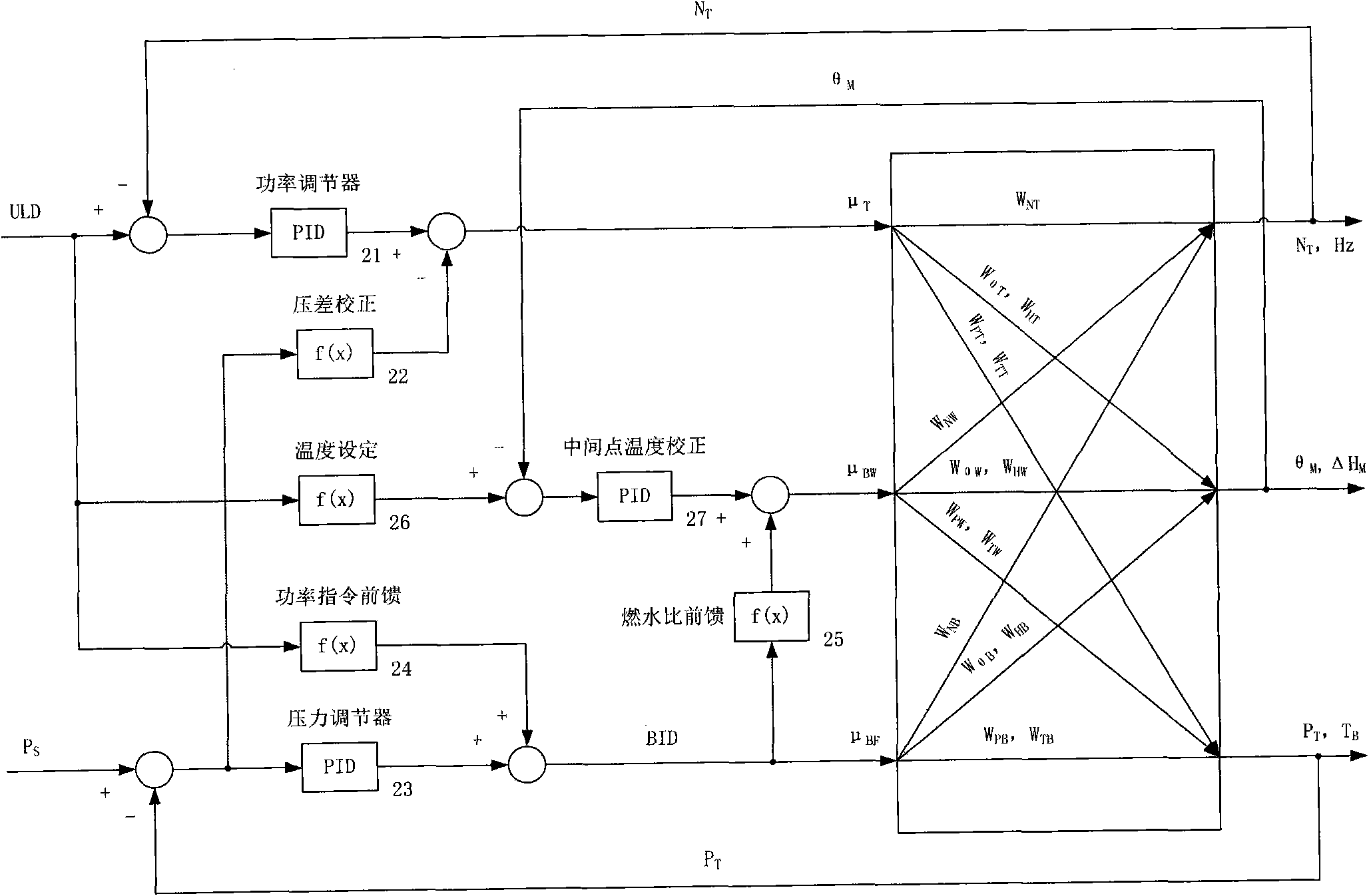

[0039] A 1000MW ultra-supercritical unit adopts the principle block diagram of the optimized direct energy-mass balance coordinated control system of the present invention as attached figure 1 As shown, the original design of the conventional once-through furnace unit unit coordination control system scheme is shown in the attached figure 2 shown.

[0040] In the original design scheme, the typical design of the coordinated control system of most once-through furnace unit units was adopted (attached figure 2 ). Among them, the steam turbine side is designed as a power regulation circuit, and the pressure deviation pull-back circuit 22 is used for correction in the steam turbine power regulation circuit, that is, when the pressure deviation is large, the action of blocking the turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com