High frequency responding high temperature drawing-twisting fatigue extender

A high-frequency response and extensometer technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the extensometer cannot be tested with high-temperature materials, the measurement range is small, and the dynamic response is slow, so as to achieve good dynamic response characteristics and use The effect of long life and small temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

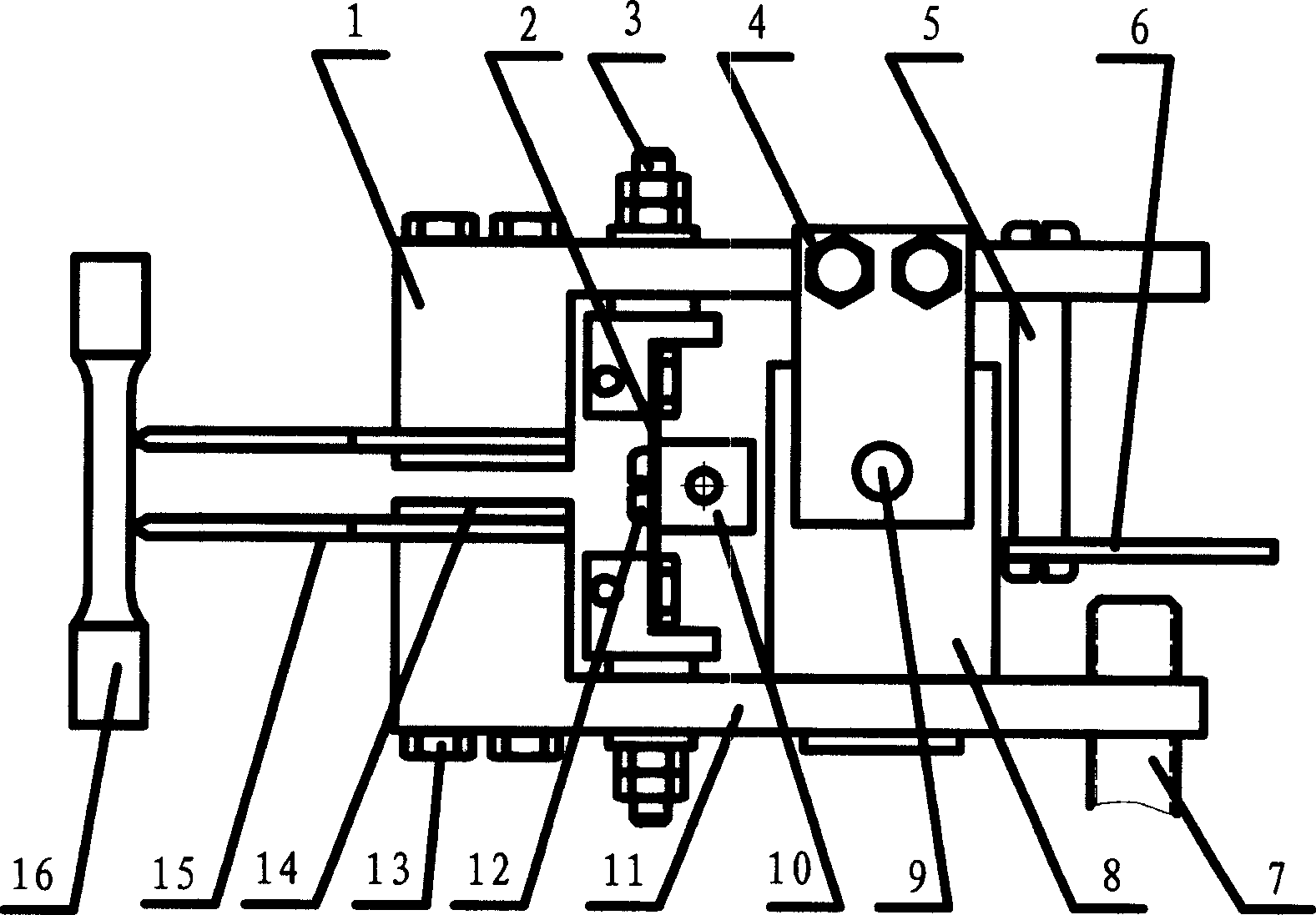

[0008] In the preparation of the present invention, the upper force plate 1, the rotating shaft 3, the support vertical plate 4, the connection vertical plate 5, the support rod 10, the lower force transmission plate 11, etc. are all made of aluminum alloy materials, and the axial reflection plate 6 and the rotation reflection plate 8. No. 45 steel is used, and the spring leaf is made of 20mm wide and 0.3mm thick 304 stainless steel sheet. Design the height of the spring leaf according to the gauge length of the required extensometer. When assembling, first use the bolts to fix the quartz thimble, then connect the spring piece 2 with the rotating shaft 3 and the support rod 10, respectively connect the supporting vertical plate 4, the connecting vertical plate 5 and the rotating reflection plate 8 with the upper force plate 1 and the lower receiving plate. The force plate 11 is connected, and finally the rotating shaft of the leaf spring and the force plate are fixed with nuts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com