Comprehensive utilization method of thermal power plant boiler wastewater

A technology for boiler blowdown and thermal power plants, applied in the direction of heating water/sewage treatment, separation methods, boiler cleaning devices, etc., can solve problems such as heat waste of sewage and hot water, pollution of the environment, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

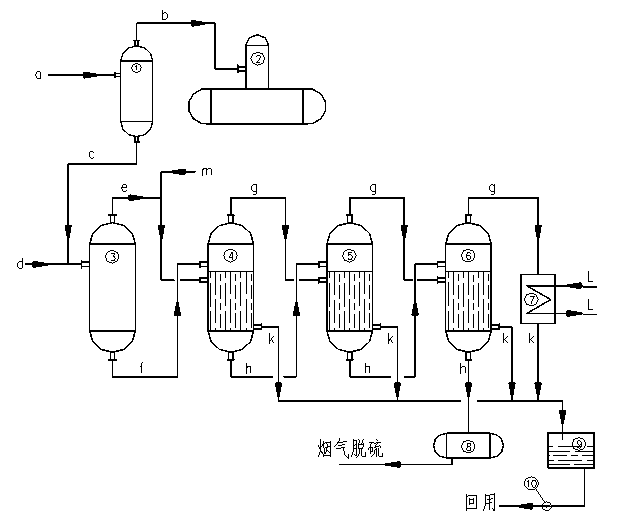

[0024] The evaporation capacity of the boiler is 420t / h, and the sewage discharge rate is 1.5%, of which the fixed discharge is 0.5%, and the continuous discharge is 1%.

[0025] (1) The boiler continuously discharges 4.2t / h of sewage, and the sewage enters the continuous expansion vessel 1 for decompression and flash evaporation; the generated 1.2t / h flash steam is drawn from the upper part of the continuous expansion vessel 1 to the deaerator 2 through a pipeline On the one hand, it participates in the deaeration of the boiler feed water, and on the other hand, it stabilizes the pressure of the continuous expansion vessel 1.

[0026] (2) Connect the 3t / h sewage hot water at the bottom of the continuous expansion vessel 1 to the fixed expansion vessel 3 of the boiler, and further reduce the pressure and flash together with the 2.1t / h sewage discharged regularly by the boiler.

[0027] (3) The 1.5t / h flash steam from the fixed row expansion vessel 3 is connected to the low-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com