Intrinsically-safe water-feeding and oxygen-adding treatment method of once-through boiler

A technology for adding oxygen to water and once-through boilers, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. It can solve problems such as low water production, shedding, corrosion and deposition of boiler water vapor systems , to achieve the effect of inhibiting FAC, slowing down the impact and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

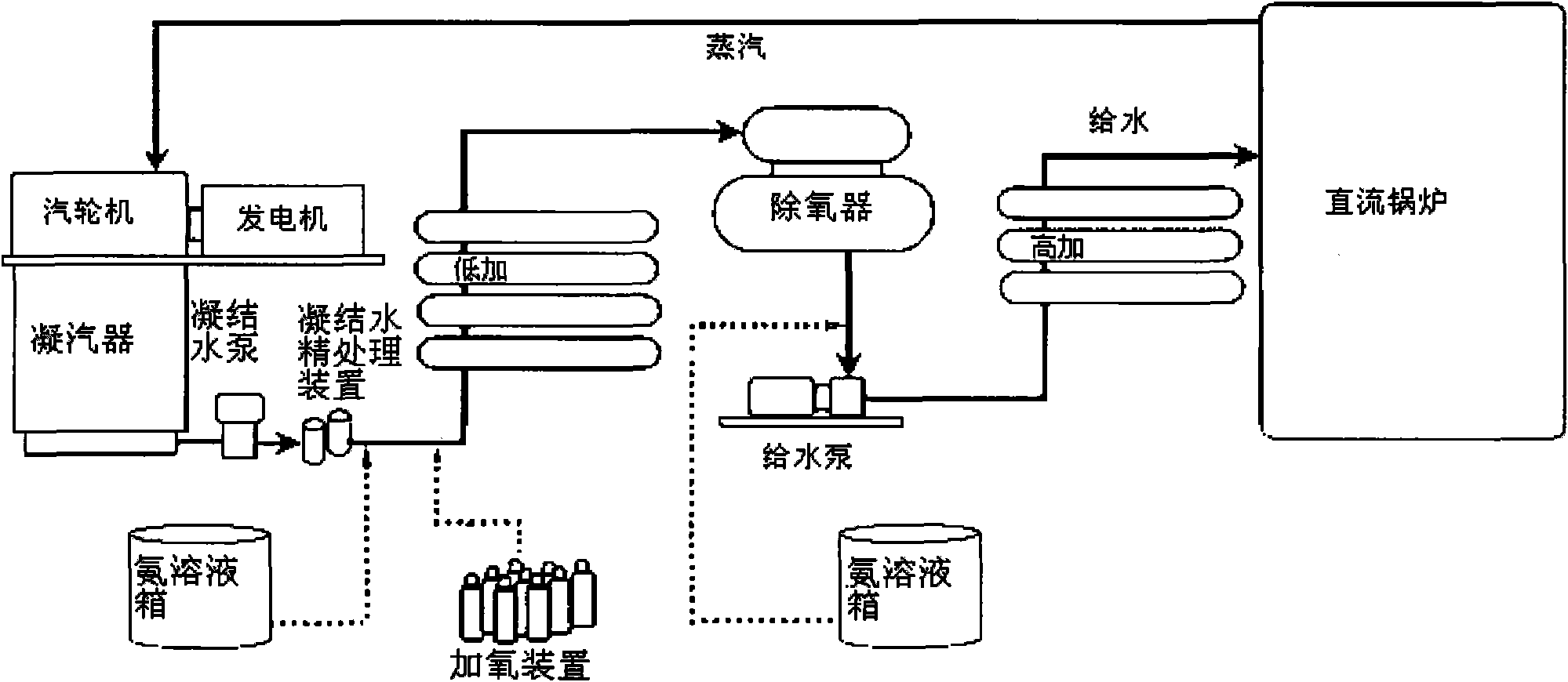

[0052] The method of ISOT applied to a 1000MW ultra-supercritical thermal power unit

[0053] (1) Feedwater treatment method at the initial stage of unit start-up

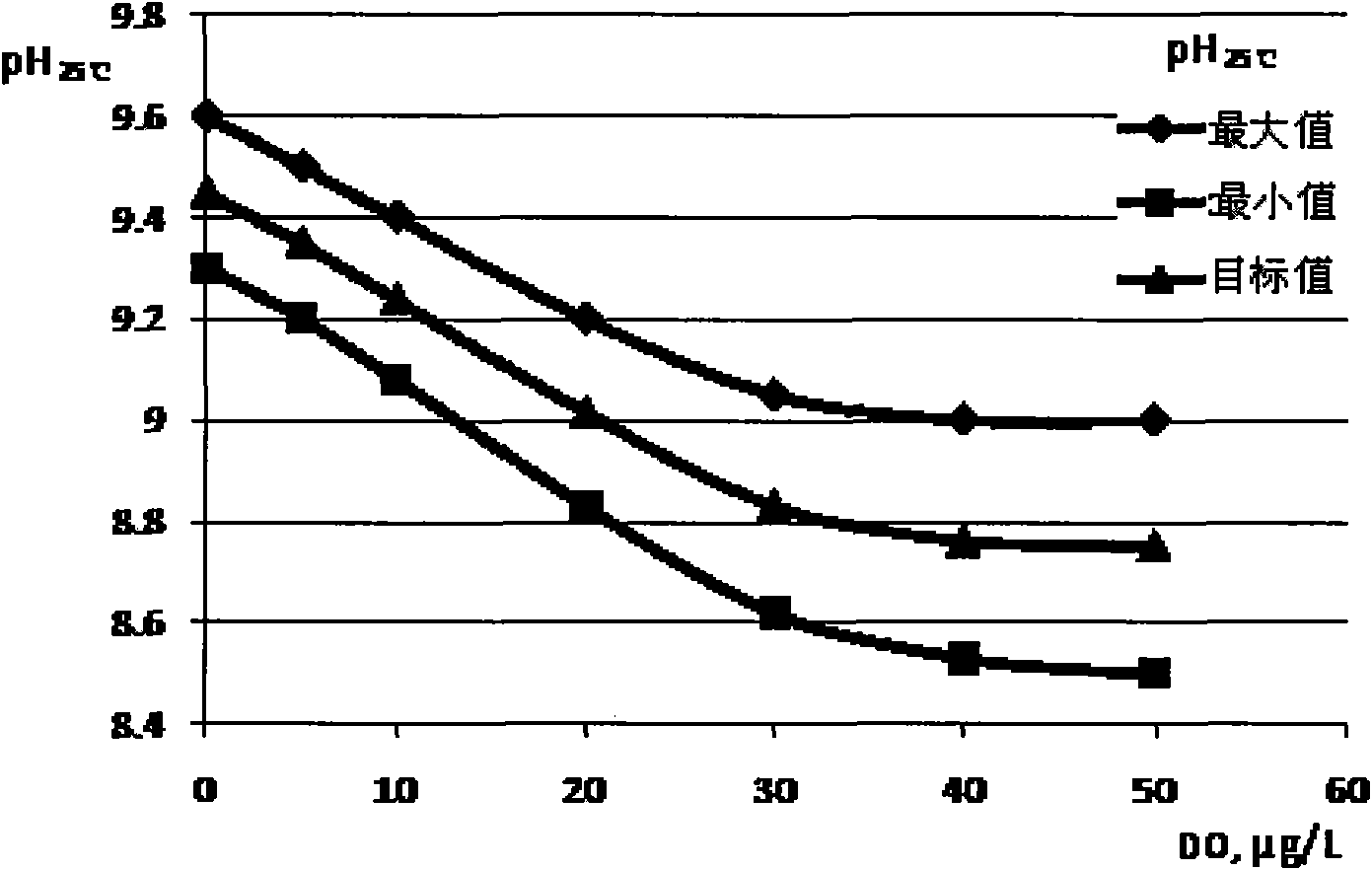

[0054] AVT (O) operation mode is adopted at the initial stage of unit start-up, that is, the feed water treatment mode is ammonia addition only. Add ammonia to adjust the pH value of the feed water at 9.3-9.6. When the AVT(O) operation mode is adopted at the initial stage of unit start-up, the exhaust valve of the deaerator should be in the normal open state.

[0055] (2) Feedwater treatment method during AVT transition period

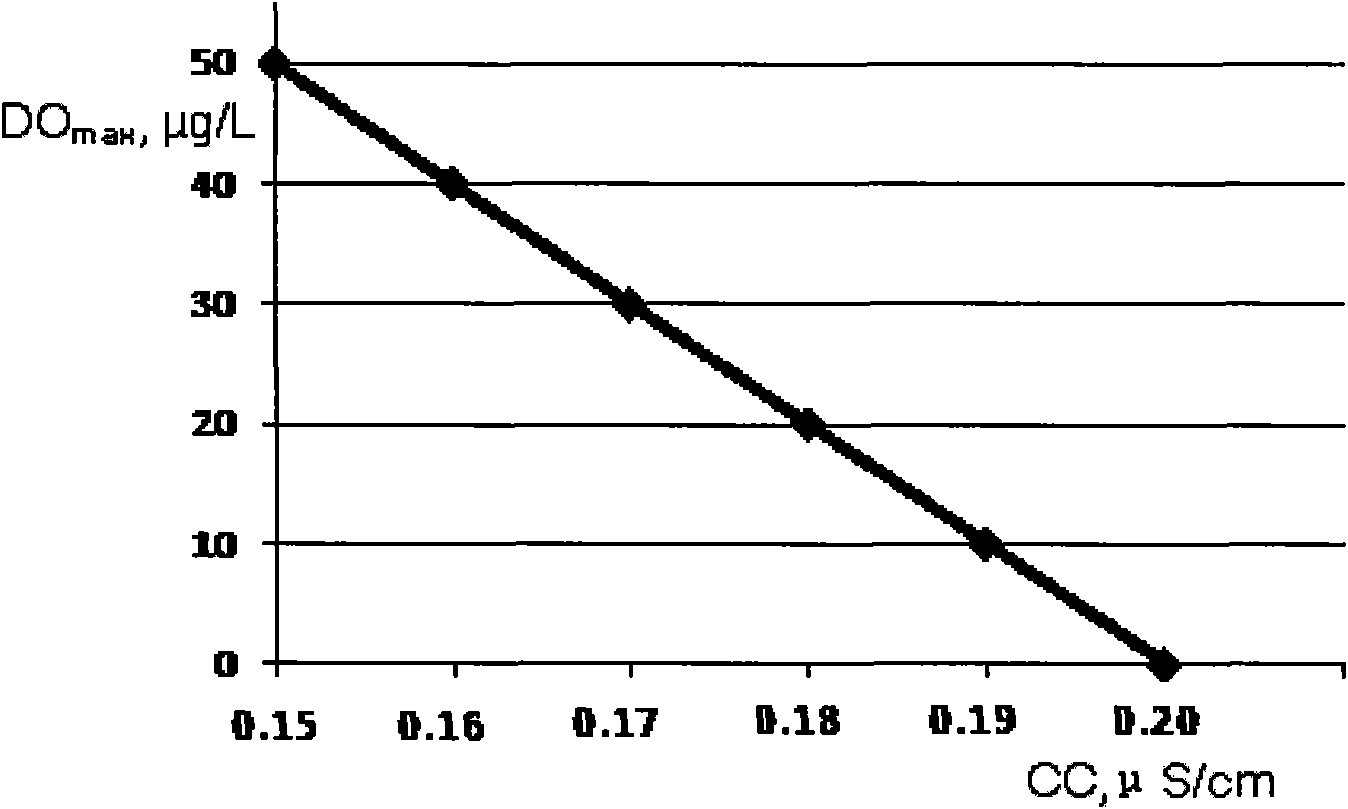

[0056] After the unit is started, when the following conditions are met: the unit is in a stable operating state; the guaranteed hydrogen conductance value of the unit feed water is ≤0.15μS / cm, and the target value is ≤0.1μS / cm; other water vapor quality indicators of the unit are normal. The transition period is more than seven days.

[0057] (3) Feedwater treatment method during the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com