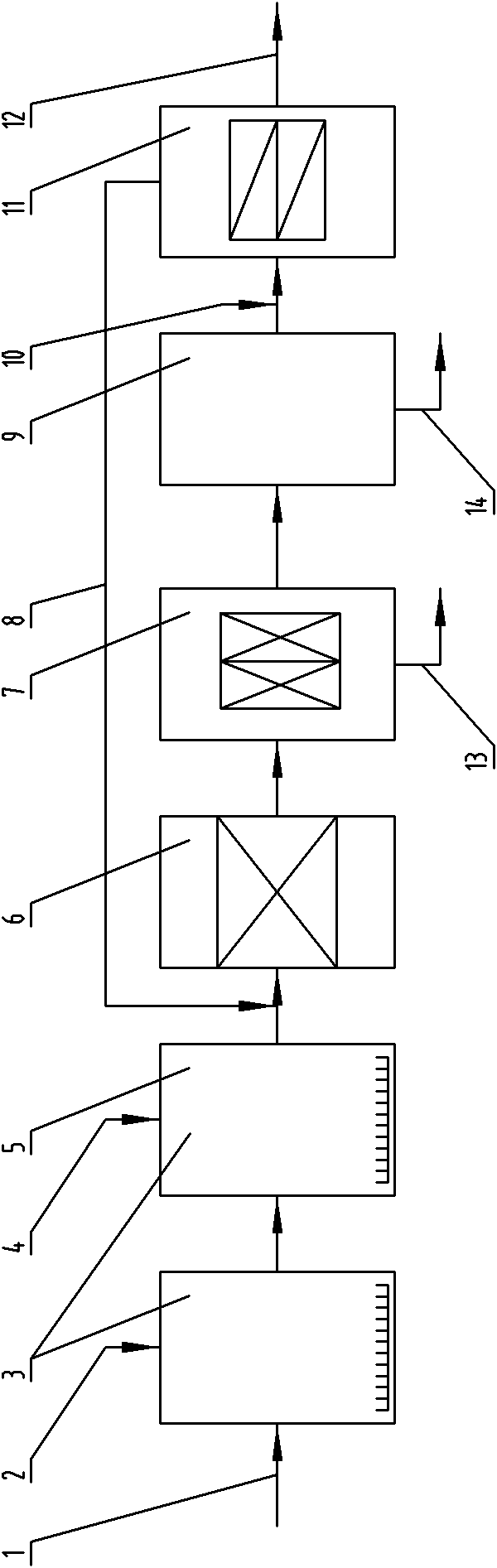

Deep stage treatment method for industrial wastewater

A technology for industrial wastewater and graded treatment, which is applied in the direction of water/sewage multi-stage treatment, separation methods, neutralized water/sewage treatment, etc. It can solve the problems of low water quality requirements, secondary pollution, poor reverse osmosis, etc. Achieve the effects of low water quality requirements, simple equipment maintenance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

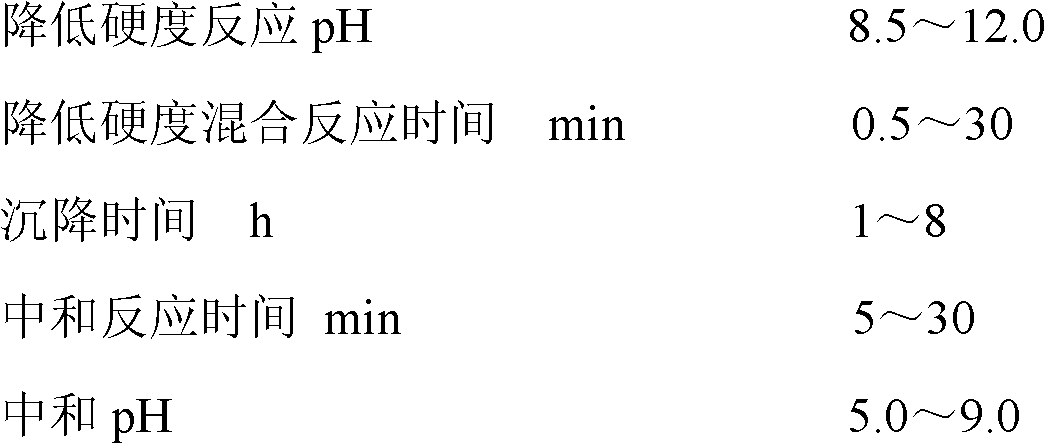

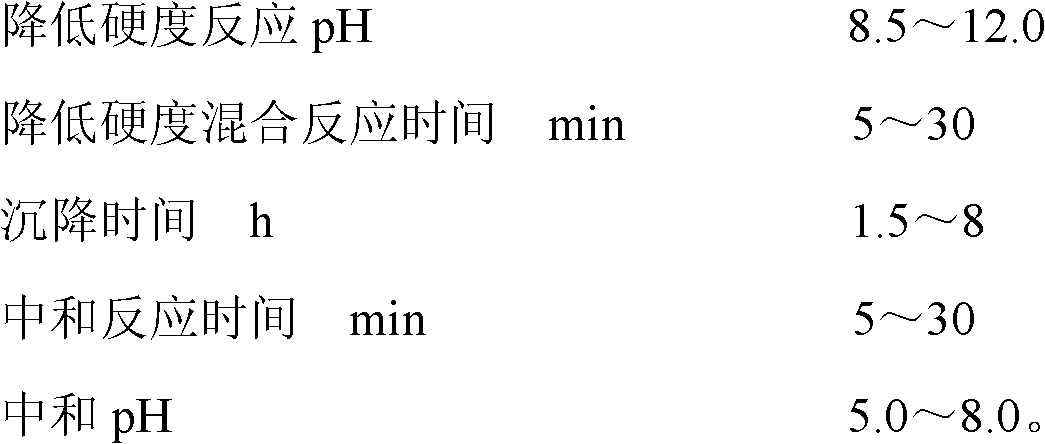

[0093] The technical scheme of the present invention is used to treat chemical sewage discharged up to the standard, and the influent water quality is 3000 μS / cm in electrical conductivity, 30 mg / L in COD, and 900 mg / L in hardness (calculated as calcium carbonate). The alkaline substance added to the initial hardness reduction operation unit is sodium hydroxide, the pH value is controlled at 10.5, the stirring method is blast stirring, and the mixing reaction time is 20 minutes. The sediment removal method is inclined plate sedimentation, and the sedimentation time is 4 hours ; The acidic substance added in the neutralization reaction is sulfuric acid, the pH value is controlled at 6.8, and the neutralization reaction time is 10 minutes. Preliminary reduction of hardness The water quality of the effluent from the operating unit is 2800 μS / cm in electrical conductivity and 200 mg / L in hardness (calculated as calcium carbonate). The filtration method of the high-efficiency filtr...

Embodiment 2

[0095] The technical scheme of the present invention is used to treat chemical sewage discharged up to the standard, and the influent water quality is 5000 μS / cm in electrical conductivity, 45 mg / L in COD, and 1000 mg / L in hardness (calculated as calcium carbonate). The basic substance added to the initial hardness reduction operation unit is sodium hydroxide, the pH value is controlled to 12.0, the stirring method is blast stirring, the mixing reaction time is 10 minutes, and the generated sediment is removed by natural sedimentation, and the sedimentation time is 6 hours; The acidic substance added in the neutralization reaction is sulfuric acid, the pH value is controlled at 7.0, and the neutralization reaction time is 10 minutes. Preliminary reduction of hardness The water quality of the effluent from the operating unit is 4600 μS / cm in electrical conductivity and 100 mg / L in hardness (calculated as calcium carbonate). The filtration method of the high-efficiency filtratio...

Embodiment 3

[0097] The technical scheme of the present invention is used to treat chemical sewage discharged up to the standard, and the influent water quality is 5000 μS / cm in electrical conductivity, 45 mg / L in COD, and 1000 mg / L in hardness (calculated as calcium carbonate). The alkaline substance added to the initial hardness reduction operation unit is sodium hydroxide, the pH value is controlled to 8.5, the stirring method is mechanical stirring, and the mixing reaction time is 30 minutes. The acidic substance added in the neutralization reaction is sulfuric acid, the pH value is controlled at 7.0, and the neutralization reaction time is 30 minutes. Preliminary reduction of hardness The water quality of the effluent from the operation unit has a conductivity of 4850 μS / cm and a hardness of 500 mg / L (calculated as calcium carbonate). The filtration method of the high-efficiency filtration operation unit is a combination of sand filtration and laminated filtration. Before sand filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com