Desalination method for offshore thickened oil thermal recovery production water

A technology for thermal recovery of heavy oil and production of water, which is applied in general water supply conservation, mining wastewater treatment, chemical instruments and methods, etc. The effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

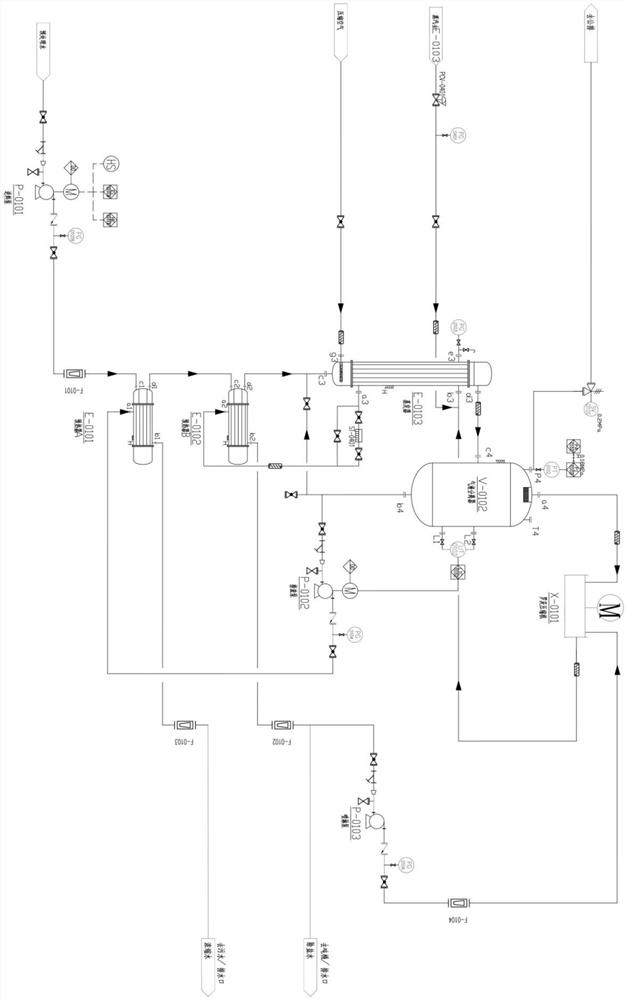

[0044] The average temperature of the front-end pretreatment water is 32°C, the average oil content is 3.5mg / L, the average suspended solids content is 0.8mg / L, and the total hardness (calculated as calcium carbonate) is 100mg / L. The incoming water enters the preheater A (E-0101) from c1 through the feed pump (P-0101), and the concentrated liquid produced by the gas-liquid separator (V-0102) enters E-0101 from a1; the water produced after heat exchange Exit from d1, enter preheater B (E-0102) from c2, steam condensate water produced by the shell side of evaporator (E-0103) exit from a3, enter E-0102 from a2; after heat exchange, the production water enters from d2 At the same time, compressed air enters the gas distributor at the bottom of E-0103 from g3, the air is discharged from the gas distributor and mixed with the production water at the bottom, and enters the evaporation tube of E-0103 together ; A small amount of steam generated by the steam generator and a large amoun...

Embodiment 2

[0046] The average temperature of the front-end pretreatment water is 35°C, the average oil content is 2.5mg / L, the average suspended solid content is 0.75mg / L, and the total hardness (calculated as calcium carbonate) is 110mg / L. The incoming water enters the preheater A (E-0101) from c1 through the feed pump (P-0101), and the concentrated liquid produced by the gas-liquid separator (V-0102) enters E-0101 from a1; the water produced after heat exchange Exit from d1, enter preheater B (E-0102) from c2, steam condensate water produced by the shell side of evaporator (E-0103) exit from a3, enter E-0102 from a2; after heat exchange, the production water enters from d2 At the same time, compressed air enters the gas distributor at the bottom of E-0103 from g3, the air is discharged from the gas distributor and mixed with the production water at the bottom, and enters the evaporation tube of E-0103 together ; A small amount of steam generated by the steam generator and a large amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com