Once-through boiler starting system and method

A once-through boiler and start-up system technology, applied in the field of electric power, can solve problems such as the unavailability of steam-saturated water, and achieve the effects of reducing pipeline usage, reducing dependence, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

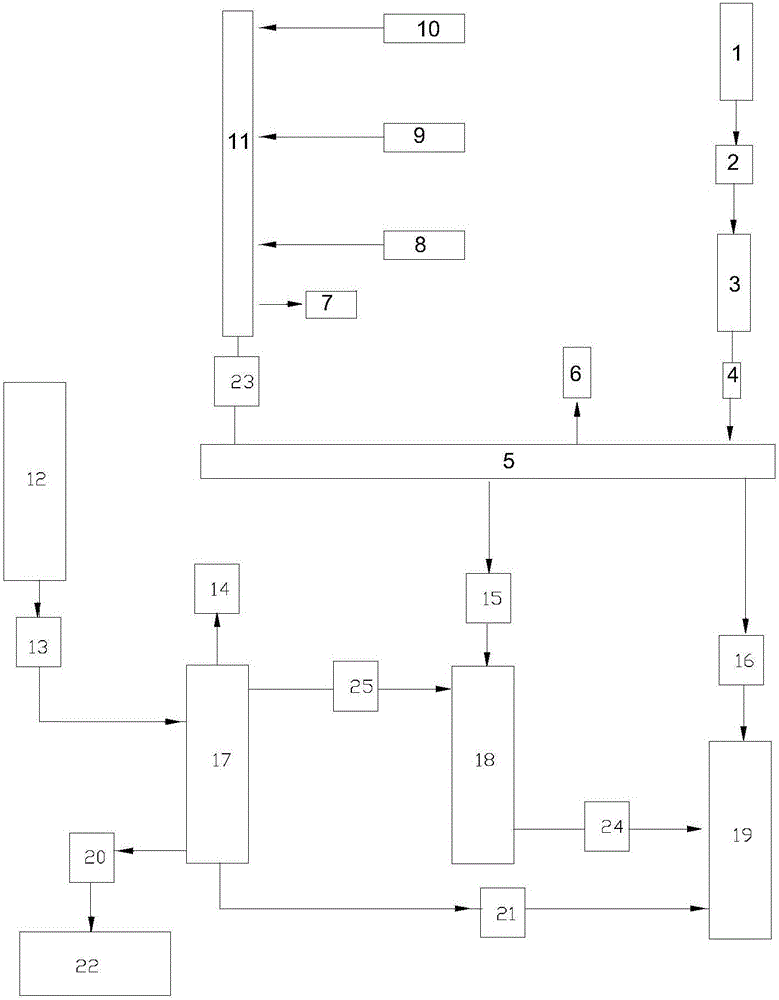

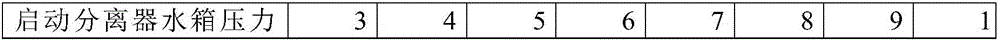

[0051] A kind of once-through boiler startup method of the present invention, specifically comprises the following steps:

[0052] Connect a pressure expansion vessel after the 361 valve of the once-through boiler of the thermal power generation unit;

[0053] Two steam pipelines are drawn from the upper part of the pressure expansion vessel, one leads to the steam side of the high-pressure heater, and the other exhausts the atmosphere;

[0054] Two water pipelines are drawn from the lower part of the pressure expansion vessel, one leads to the water supply pipe of the deaerator, and the other leads to the unit drainage tank;

[0055] During the start-up process of the unit, if the water quality is unqualified, the water will be discharged to the unit drainage tank through the pressure expansion vessel, and the water quality will be recycled to the deaerator after the water quality is qualified;

[0056] The water level of the pressure expansion vessel is controlled by the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com