Manufacturing method of stainless steel faucet

A manufacturing method and stainless steel technology are applied in the manufacturing field of forming faucets using stainless steel pipes and stainless steel sheets, which can solve the problems of shortened service life of finished products, high casting melting point, and high production labor intensity, and achieve long duration, long service life, Long-lasting effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

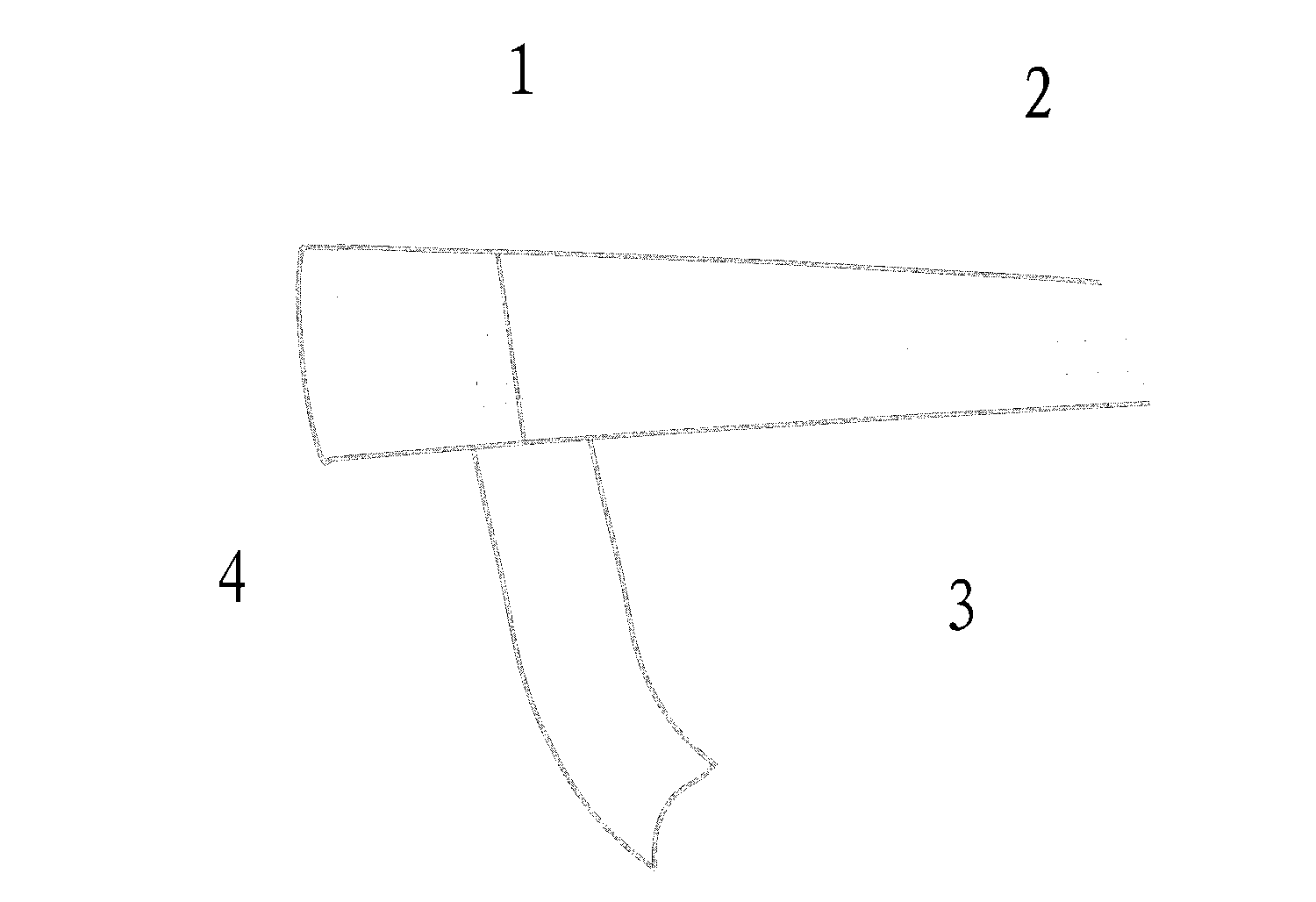

[0020] Such as figure 1 As shown, the stainless steel faucet made by the present invention is composed of a stainless steel handle (not shown in the figure), a stainless steel valve body 1, a stainless steel water-proof layer 4, a stainless steel fixing layer 3 and a stainless steel water pipe 2 in the stainless steel valve body 1.

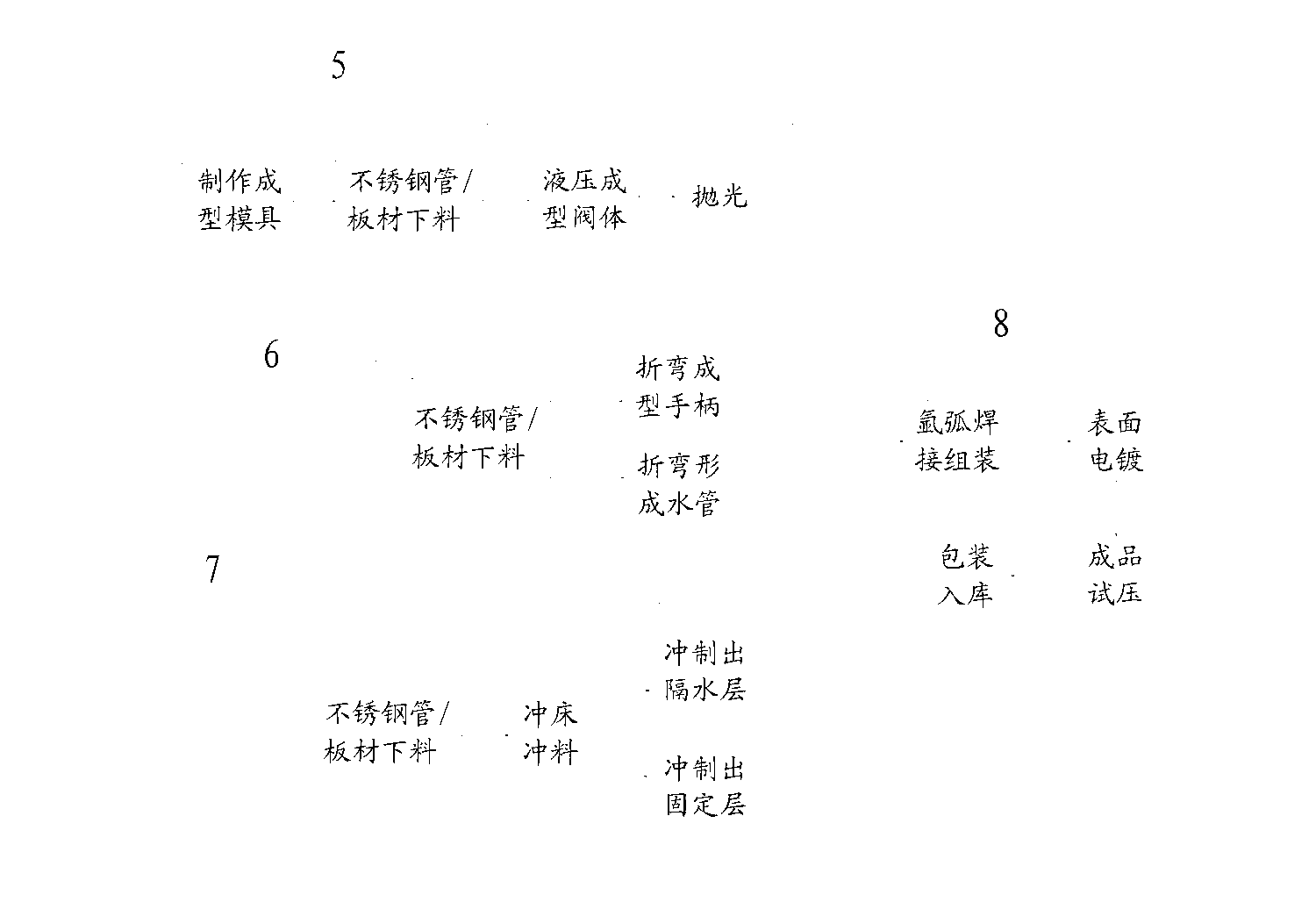

[0021] Such as figure 2 As shown, the manufacturing method of the above-mentioned stainless steel faucet is completed by the following specific steps:

[0022] The first step, the production of the outer contour of the faucet valve 5: Use the blanking mold to blank the stainless steel pipe or stainless steel plate. If the stainless steel plate is used for blanking, it needs to be welded into a steel pipe by argon arc welding; after blanking, put it into the forming mold Inside, it is transported to the hydraulic equipment for hydroforming to obtain the outline blank of the stainless steel valve body, and the forming mold is a model that matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com