Application of double-TIG welding method to implementation of thick plate welding

A welding method and welding system technology, which is applied in the field of welding and TIG welding, can solve the problems of insignificance and increase the effect of welding penetration, and achieve the effect of improving welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

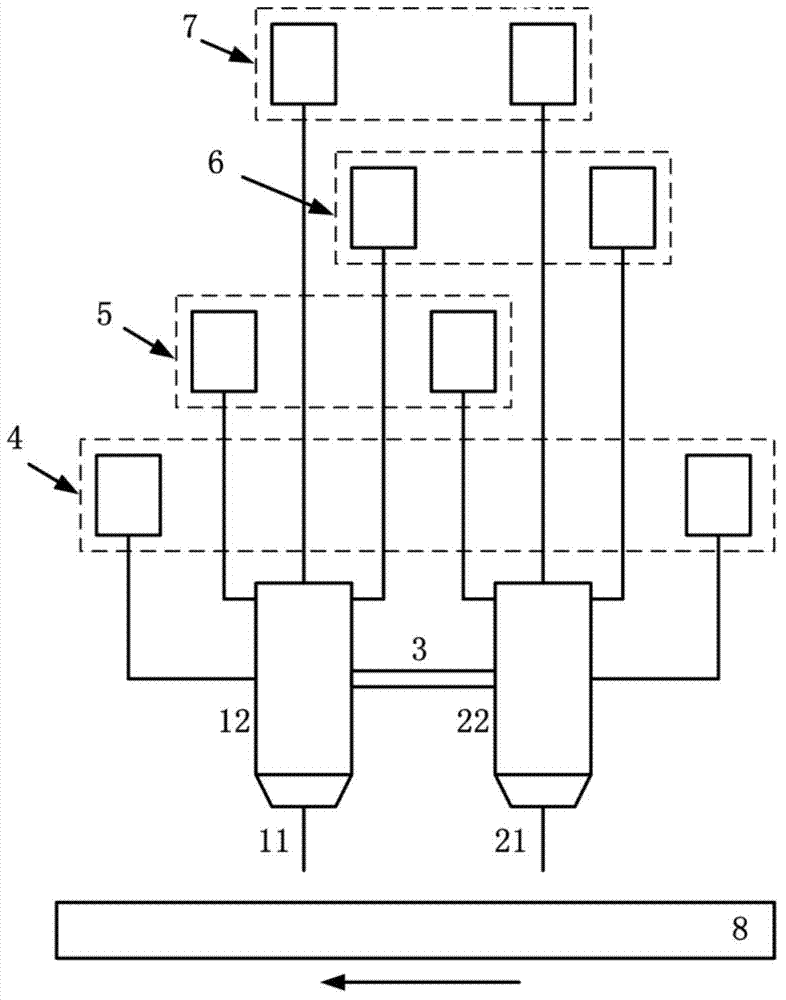

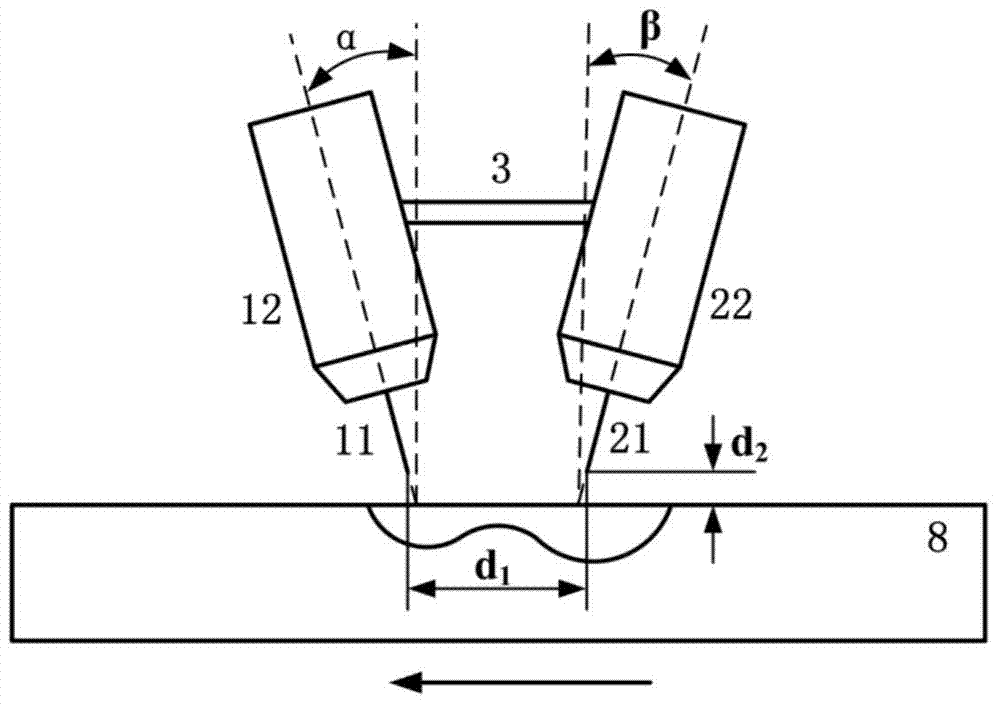

[0036] This welding process is especially aimed at welding workpieces with a thickness of 10mm, without opening grooves.

[0037] Along the welding direction, the first welding torch 12 is located at the front end, and the second welding torch 22 is located at the rear end. During welding, the first tungsten electrode 11 plays the role of initially forming the weld pool, and the second tungsten electrode plays the role of increasing the penetration depth and realizing the penetration of the plate.

[0038] Before welding, use the welding torch attitude adjustment device 4 to adjust the first welding torch 12 and the second welding torch 22 respectively, the angle between the first tungsten pole 11 and the vertical line of the plane to be welded is α, the second tungsten pole 21 and the plane to be welded The included angle is β, and the distance between the first tungsten pole, the second tungsten pole and the workpiece surface is d 2 . Let the angle α be 0°, the angle β be ...

Embodiment 2

[0042] This welding process is especially aimed at welding workpieces with a thickness of 14mm, without opening grooves.

[0043] Along the welding direction, the first welding torch 12 is located at the front end, and the second welding torch 22 is located at the rear end. During welding, the first tungsten electrode 11 plays the role of initially forming the weld pool, and the second tungsten electrode plays the role of increasing the penetration depth and realizing the penetration of the plate.

[0044] Before welding, use the welding torch attitude adjustment device 4 to adjust the first welding torch 12 and the second welding torch 22 respectively, the angle between the first tungsten pole 11 and the vertical line of the plane to be welded is α, the second tungsten pole 21 and the plane to be welded The included angle is β, and the distance between the first tungsten pole, the second tungsten pole and the workpiece surface is d 2 . Let the angle α be 0°, the angle β be ...

Embodiment 3

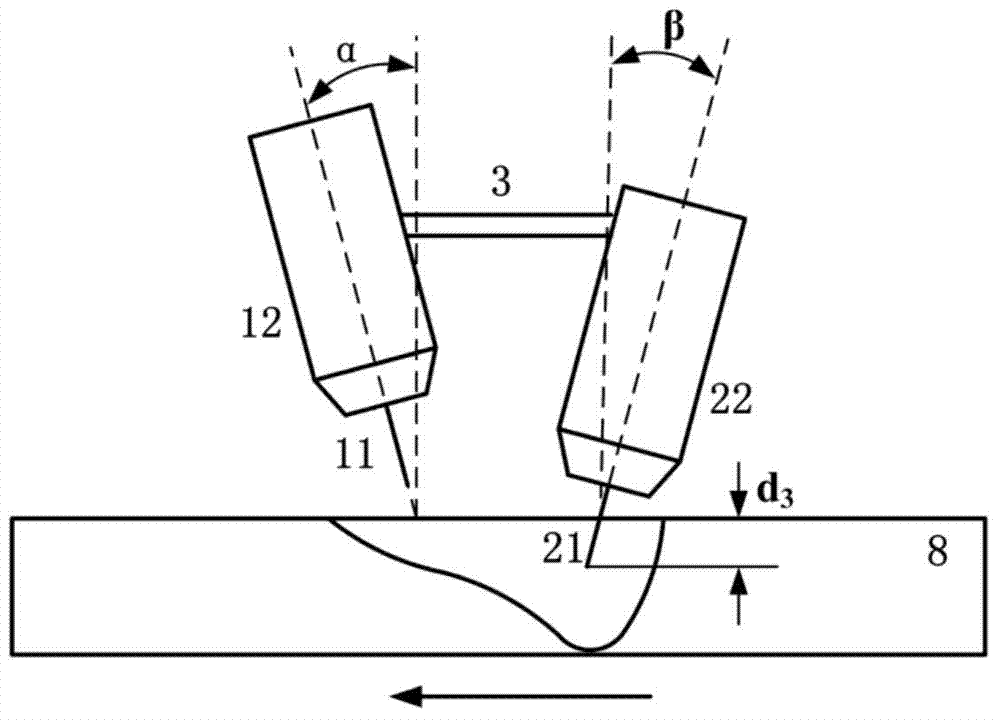

[0048] This welding process is especially aimed at welding workpieces with a thickness of 16mm, without opening grooves.

[0049] Along the welding direction, the first welding torch 12 is located at the front end, and the second welding torch 22 is located at the rear end. During welding, the first tungsten electrode 11 plays the role of initially forming the weld pool, and the second tungsten electrode plays the role of increasing the penetration depth and realizing the penetration of the plate.

[0050] Before welding, use the welding torch attitude adjustment device 4 to adjust the first welding torch 12 and the second welding torch 22 respectively, the angle between the first tungsten pole 11 and the vertical line of the plane to be welded is α, the second tungsten pole 21 and the plane to be welded The included angle is β, and the distance between the first tungsten pole, the second tungsten pole and the workpiece surface is d 2 . Let the angle α be 0°, the angle β be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com