Active agent for tungsten electrode argon arc welding and using method thereof

A technology of argon tungsten arc welding and active agent, which is applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve the problems of inconvenient use of flux, human injury, etc., and achieve simple use method, beautiful appearance of weld surface, Effect of reducing welding cost

Active Publication Date: 2014-05-07

SHANGHAI SHIPBUILDING TECH RES INST +1

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The flux currently on the market is inconvenient to use. It is usually mixed with acetone before use, and then welded after the acetone volatilizes, and the active agent contains fluoride or halide. Long-term use will cause great harm to the human body.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] (1) Welding materials and equipment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an active agent for tungsten electrode argon arc welding. The active agent is characterized by comprising, by weight, 18 to 22% of silicon dioxide, 9 to 16% of potassium dioxide and 62 to 73% of water and the active agent is placed in shade to be sealed and stored at room temperature. According to the active agent which is non-toxic and free of halide and fluoride, the composition is simple and the using method is simple; welding arcs can contract, the welding penetration can be increased, the welding efficiency can be improved, the welding cost can be reduced, the welding deformation can be reduced, satisfactory welding seams can be obtained, and residues are less; the active agent is suitable for welding of various stainless steel and carbon steel materials and a groove can be omitted, one-step welding penetration can be achieved, and one-side welding with two-sided forming can be achieved for abutting welding seams of the stainless steel and the carbon steel if the thickness of the stainless steel and the carbon steel is below 8.5 mm.

Description

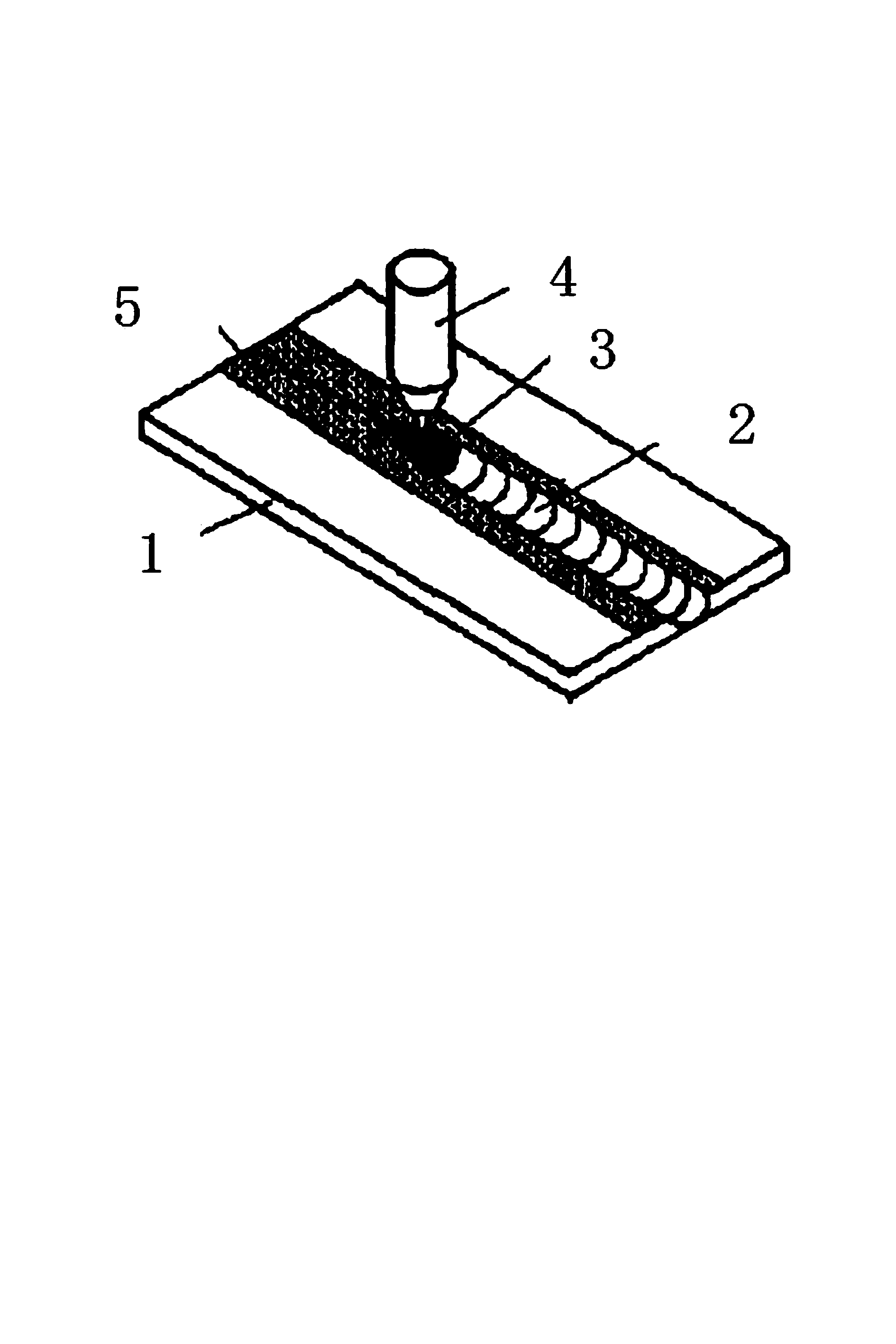

technical field [0001] The invention relates to the technical field of metal welding, in particular to an active agent for argon tungsten arc welding. Background technique [0002] Tungsten argon arc welding (TIG) can be used for the connection of all metals, but because of its shallow welding penetration, it is usually butt jointed at a thickness of more than 3mm. weld. Therefore, when TIG is used to weld thick plates, there are disadvantages such as large welding deformation, low welding efficiency, and high production cost, which cannot meet the production requirements. [0003] Active tungsten argon arc welding (A-TIG) was first proposed by the Ukrainian Barton Welding Institute in 1965, such as figure 1 As shown, this technology is to apply a layer of active flux with special chemical composition on the area to be welded before welding. Using normal welding specifications during welding can greatly increase the welding penetration. During welding, the active agent ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/362B23K9/235B23K9/167

CPCB23K9/02B23K9/167B23K9/235B23K35/3607

Inventor 郑惠锦段灿刘鹏兰玲甘露

Owner SHANGHAI SHIPBUILDING TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com