Robot laser-electric arc hybrid welding device and method

A hybrid welding and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as low welding efficiency, unsuitable three-dimensional space welds, and submerged arc welding efficiency cannot be maximized. , to achieve the effect of improving production efficiency, practical value of large projects, and convenient three-dimensional operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

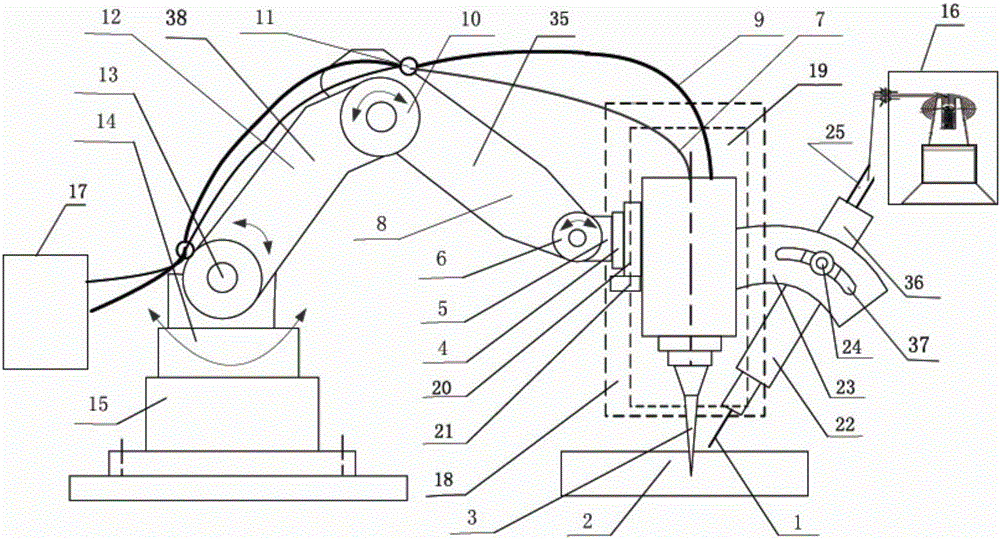

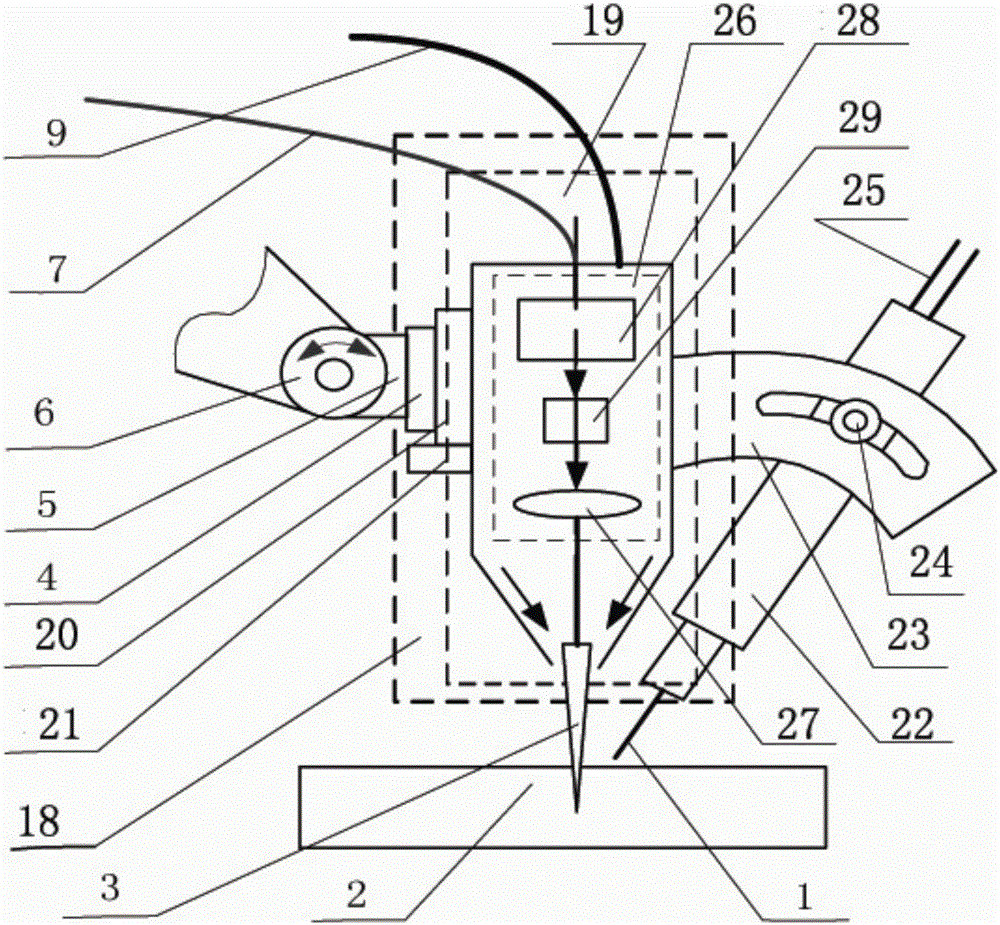

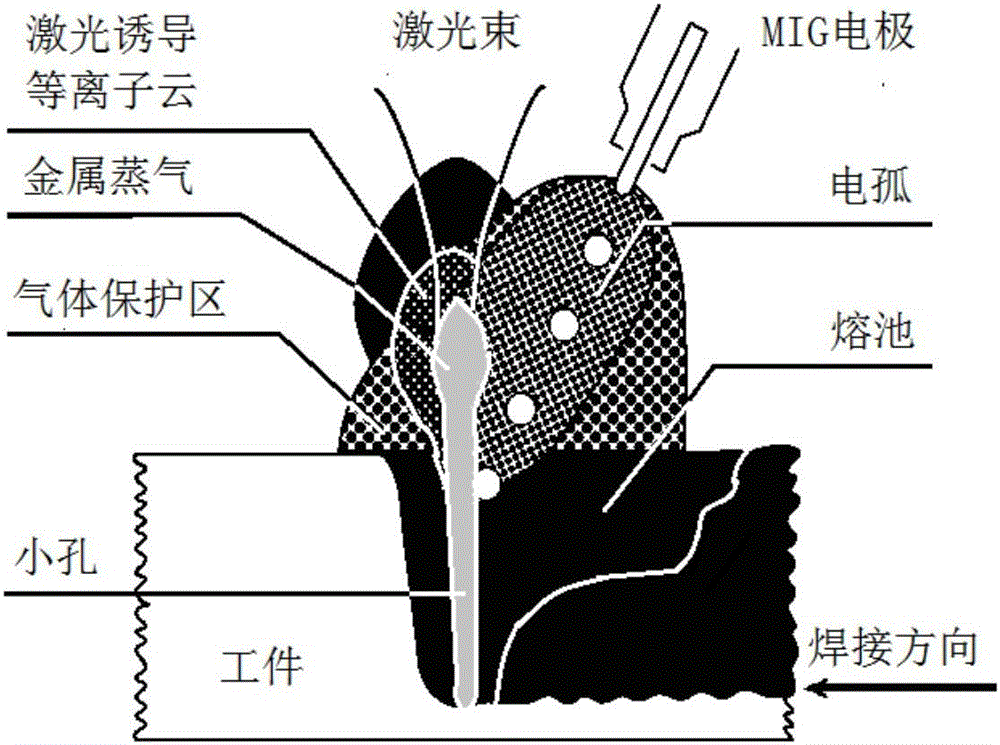

[0025] Such as figure 1 As shown, a robot laser-arc hybrid welding device and method is composed of a robot laser welding device 35, a MIG welding device 36, and a control unit; the robot laser welding device 35 includes a fiber laser and a control unit 17, a welding robot 38. The laser head unit 18, the MIG welding device 36 includes an arc welding torch 22, a welding torch adjustment fixture 23, and an intelligent wire supply device 16; the intelligent wire supply device 16 is connected to the tail of the arc welding torch 22 to provide welding wire for it, and the The arc welding torch 22 is installed on the welding torch adjustment fixed frame 23, and the welding torch adjustment fixed frame 23 is installed on the laser head 19 of the robot laser welding device 35, and the control unit is connected with the robot laser welding device 35 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com