Dual-laser beam hybrid welding device and hybrid welding method

A hybrid welding and laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low absorption efficiency and energy conversion efficiency, porosity and embrittlement, low welding penetration, etc., and achieve simple structure Small size, increased welding penetration, and increased absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

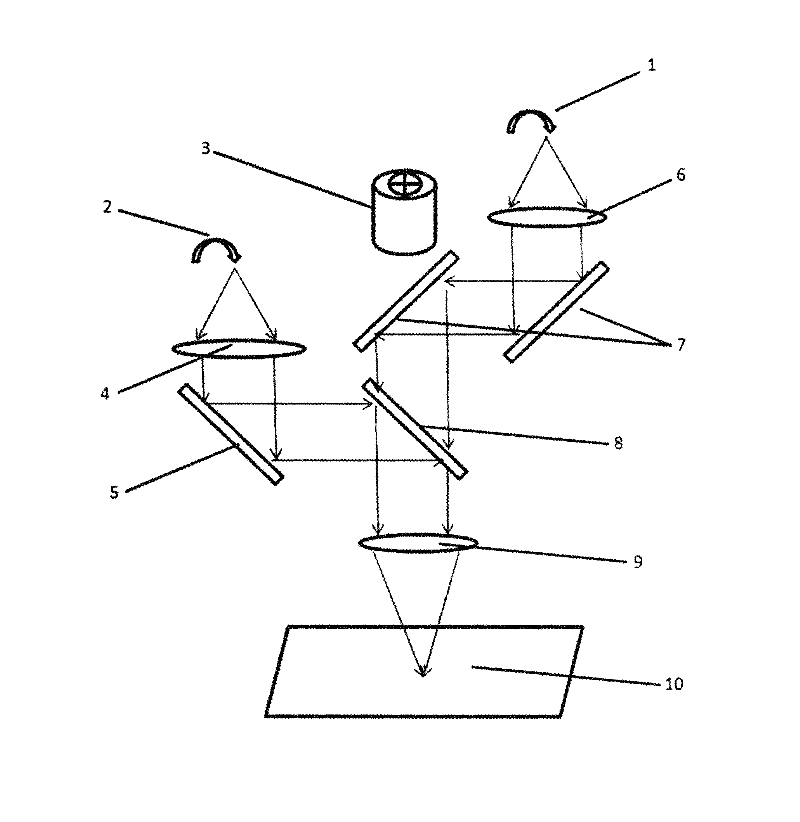

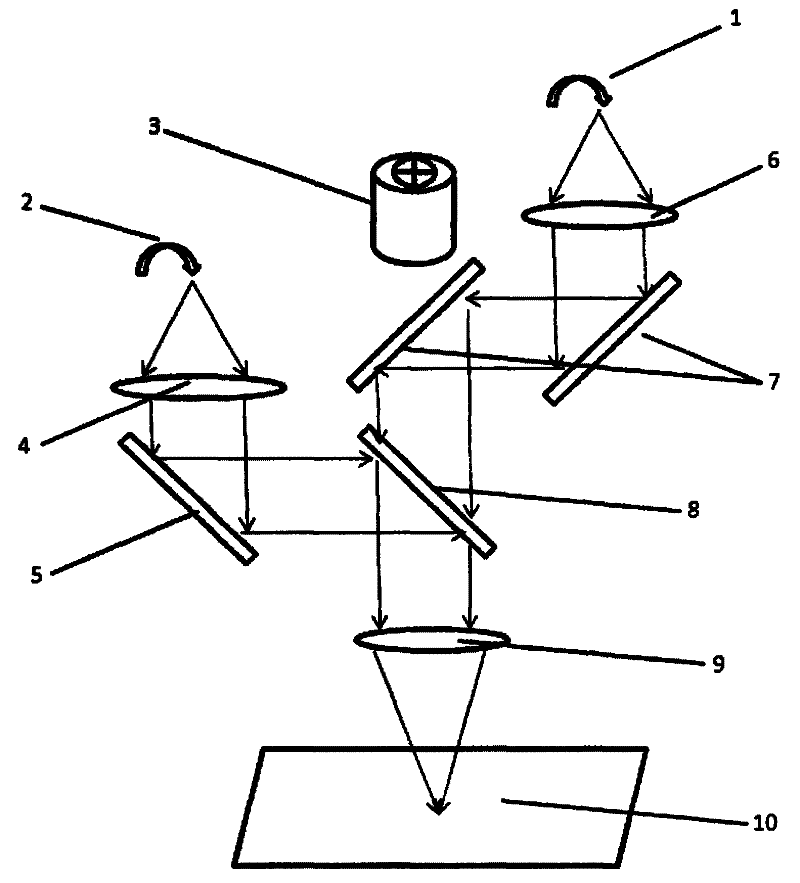

[0038] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

[0039] A double laser beam composite welding device with optical paths as shown in the accompanying drawings is used for welding a workpiece 10 placed on a horizontal welding table, including a CCD monitor 3 placed directly above the workpiece 10 to observe the welding effect in real time, And the ND:YAG laser beam optical path that is positioned at CCD monitor 3 sides, ND:YAG laser beam optical path comprises the ND:YAG collimating lens 6 that is arranged on the vertical section of anti-L type ND:YAG laser lens tube body, is arranged on anti-L The first ND:YAG total reflection lens 7 with an angle of 45° with the horizontal worktable in the turning section of the type ND:YAG laser lens barrel.

[0040] A semiconductor laser beam optical path is provided, and its semiconductor laser beam 2 is parallel to the ND:YAG laser beam 1. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com