Process and device for rotating and extending pile and slurry feed device

A construction technique and grouting technique, which is applied to sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of saving engineering costs, clear technological process, and guaranteed quality and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

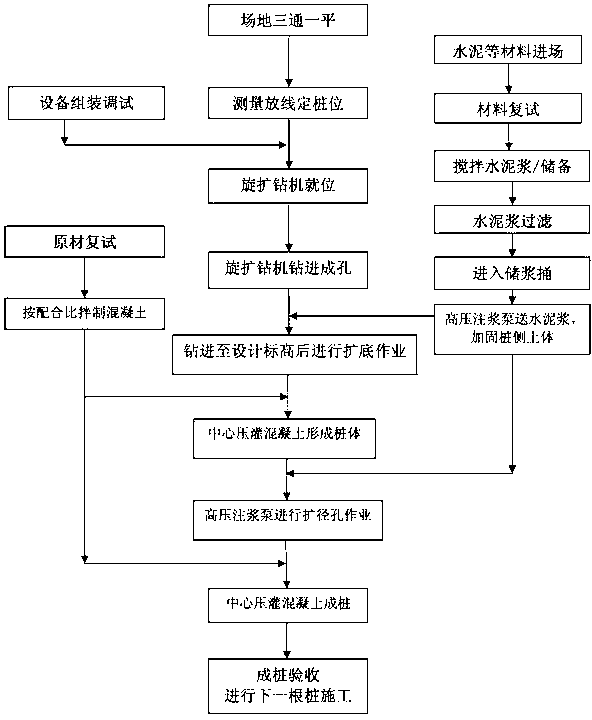

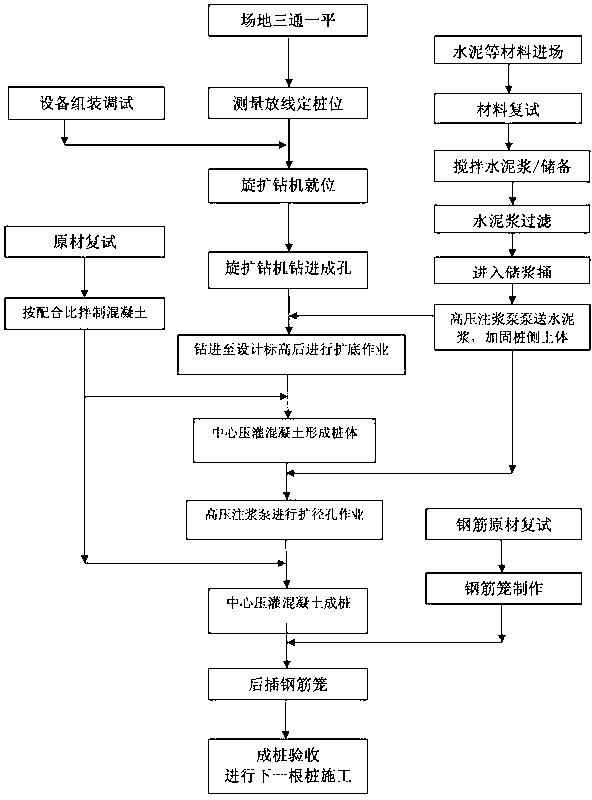

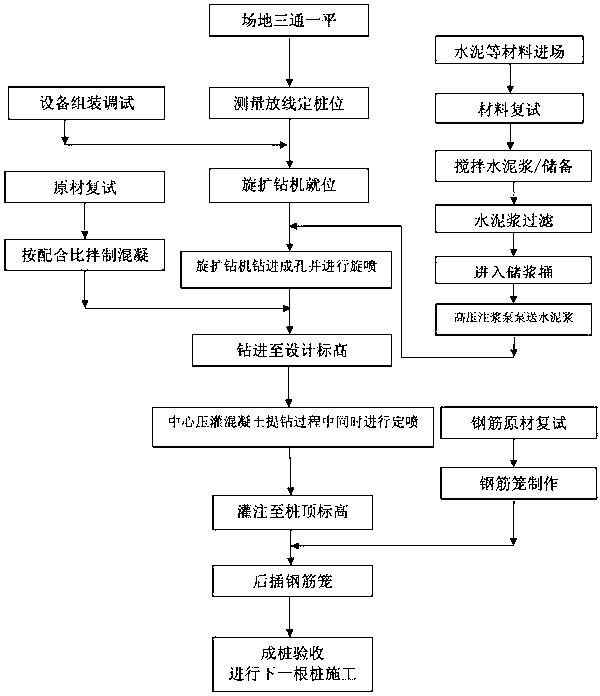

[0029] Such as Figure 1 to Figure 6 As shown, the construction technology of the rotary expansion pile of the present invention is based on the mature technology of pile drilling with auger drilling machine and pumping concrete center pressure filling to form a pile, and proposes a new mechanism for reinforcing the pile side and pile bottom soil. While the rotary expansion pile drilling rig is forming the hole, the high-pressure grouting pump is activated to form a high-pressure jet of cement slurry through the grouting device, and the high-pressure jet of cement slurry can damage and cut the soil structure around the lower part of the pile, and make a certain range around the pile The soil and cement slurry in the pile are fully mixed, effectively changing the physical and mechanical properties of the soil around the pile, and greatly increasing the resistance of the pile.

[0030]Preferably, according to the needs of engineering design, the pile body is formed at a suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com