Sectional dynamic machine-oil pressure fault inspecting system of engine

An engine oil, dynamic detection technology, used in engine testing, engine components, machines/engines, etc., can solve problems such as undetectable and low oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

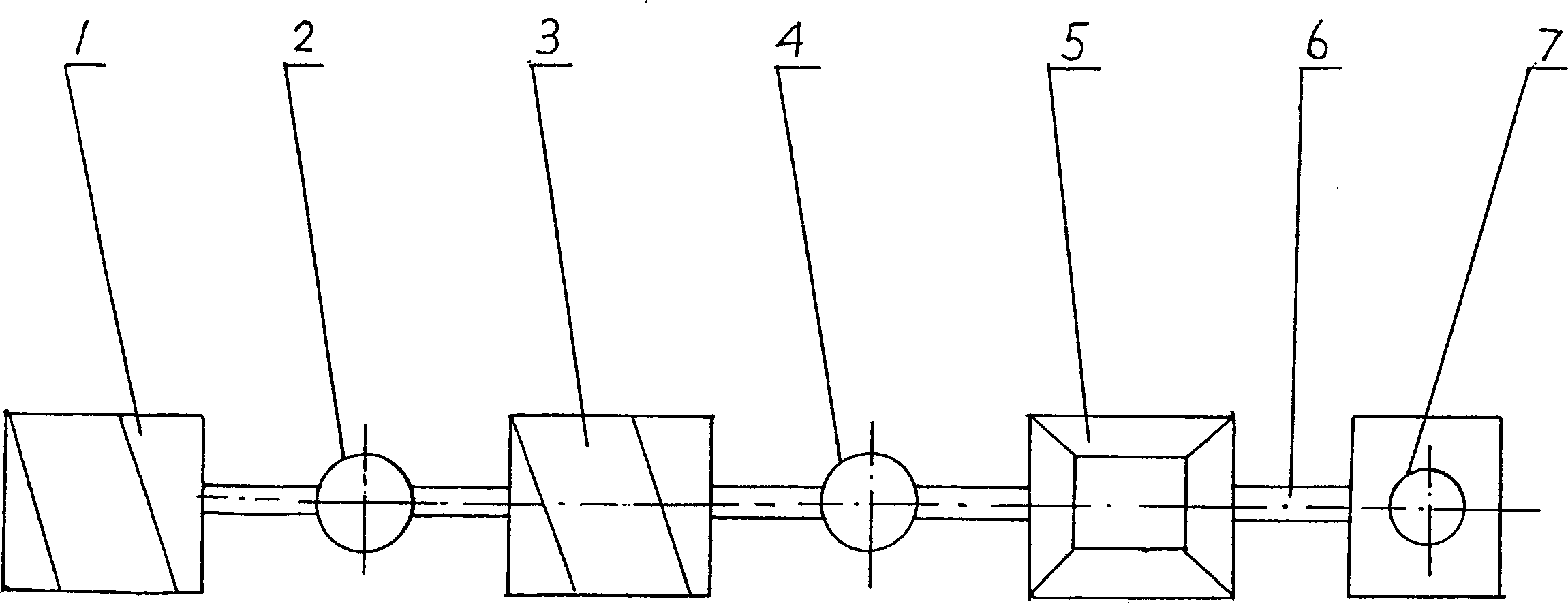

[0007] Preferred modes of the present invention are given by the following drawings.

[0008] see figure 1 , engine oil pressure failure segmentation dynamic detection system, engine lubrication system consists of oil pump (1), oil cooling filter (3), main oil passage (5), oil pipeline (6) and terminal pressure monitoring gauge (7 ) composition, between the outlet of the oil pump (1) and the inlet of the oil cooling filter (3) and between the outlet of the oil cooling filter (3) and the inlet of the main oil passage of the engine (5), take the removal of the lubrication system In the method of the middle bulkhead, a disc-shaped first intermediate pressure gauge (2) and a disc-shaped second intermediate pressure gauge (4) are respectively installed in series at the original position where the bulkhead is installed. The measuring ranges of the two intermediate pressure gauges are both (0~10) Kg / cm 2 . When the engine is placed on the test bench and is in running state, by com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com