Method for establishing pressure intensity-ultrasonic reflectivity curve for pressure intensity detection on joint surface

A construction method and pressure detection technology, which is applied in the processing of detection response signals and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as low detection accuracy, inaccurate pressure-reflectivity curves, and large gaps in calculation results. Achieve the effect of high detection accuracy, small gap and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

[0028] The method for constructing the pressure-ultrasonic reflectivity curve for joint surface pressure detection in the present invention is implemented according to the following steps:

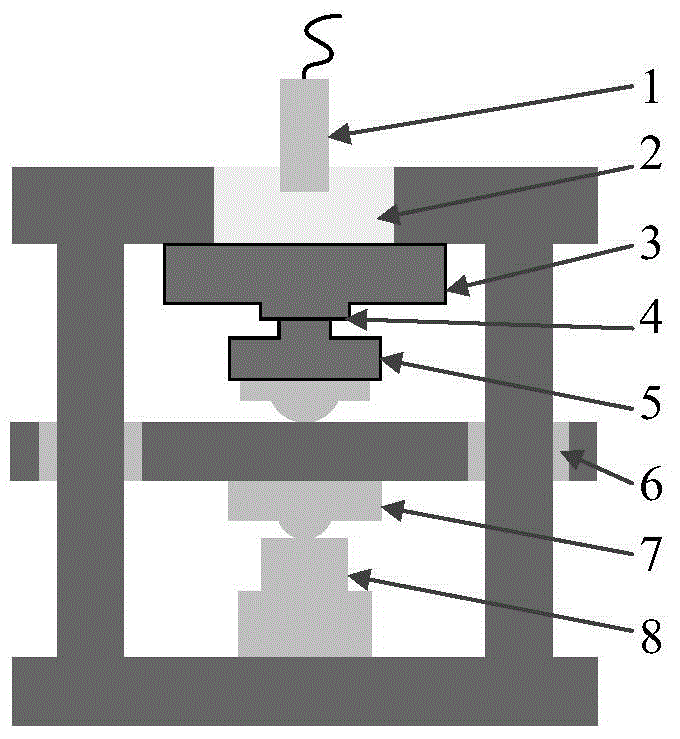

[0029] 1) In order to detect the contact pressure distribution of the bolt joint surface, process two test pieces according to the same material and surface roughness as the bolt joint surface, and install the test pieces on the pressure loading test bench, see figure 1 ,exist figure 1 Among them, 1 is the ultrasonic probe, 2 is water, 3 is the upper test piece, 4 is the joint surface to be tested, 5 is the lower test piece, 6 is the bearing, 7 is the pressure sensor, and 8 is the hydraulic jack.

[0030] 2) Obtain the reference signal: when the combined test piece is not in contact, use the Olympus V319 15MHz water immersion focused ultrasonic probe to align the test piece (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com