Dual clutch

A dual clutch, clutch housing technology, applied in clutches, fluid drive clutches, mechanical drive clutches, etc., can solve the problem that the operating bearing cannot be discharged well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

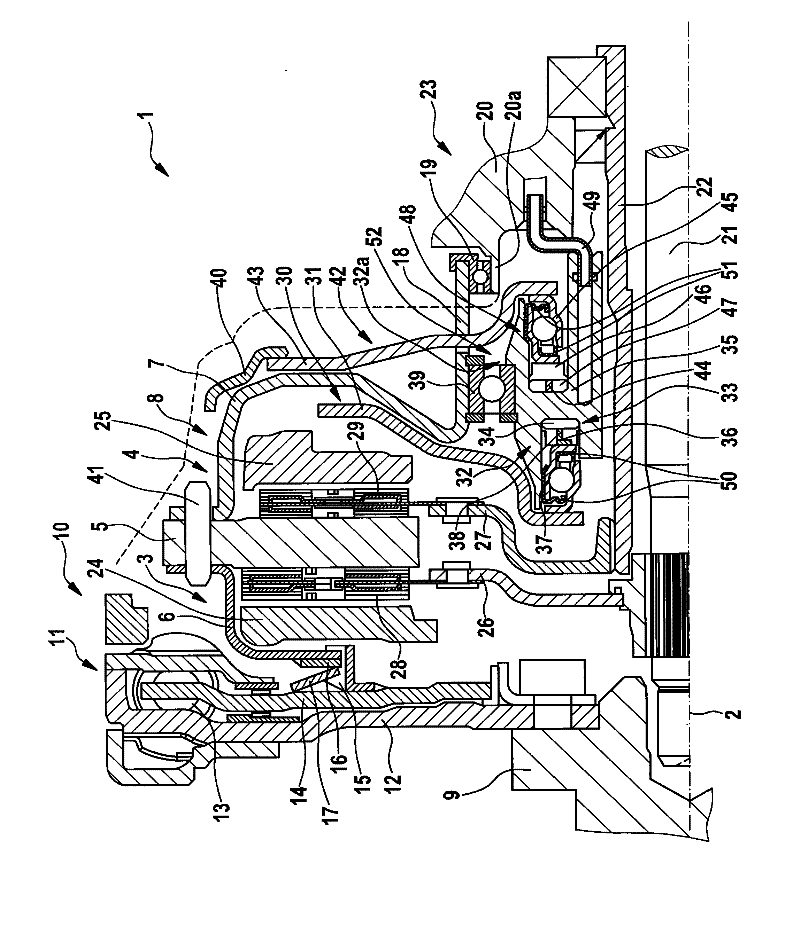

[0037] figure 1 A partial section of the dual clutch 1 above its axis of rotation 2 is shown. The dual clutch 1 comprises two friction clutches 3 , 4 which have a common central pressure plate 5 which is firmly connected to the housing parts 6 , 7 of the clutch housing 8 . The clutch housing 8 is driven by a crankshaft 9 of a not shown internal combustion engine. To this end, in the exemplary embodiment shown, a torsional vibration damper 10 , here in the form of a dual-mass flywheel 11 , is connected to the input part 12 of the crankshaft 9 . The output part 14 , which can be twisted to a limited extent relative to the input part 12 against the action of the energy store 13 , has an axially protruding profiled toothing 15 into which a complementary profiled toothing 16 engages, such as the housing shown Internal toothing of part 6. In this case, the dual clutch 1 is relative to the crankshaft 9 and relative to the torsional vibration damper 10 by means of an axially actin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com