Method for designing groove curvature radius coefficient of four-point contact ball bearing

A four-point contact and radius of curvature technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of bearing capacity and fatigue life, which are greatly affected and unreliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The allowable contact stress of the four-point contact ball bearing is 4200MPa, and the safety factor ,but .

[0065] Taking a certain type of double-row four-point contact ball bearing as an example, the structural parameters and material parameters are as follows:

[0066] , , , , , , . The ultimate working conditions of this type of bearing are: axial force , overturning moment , F r =0kN.

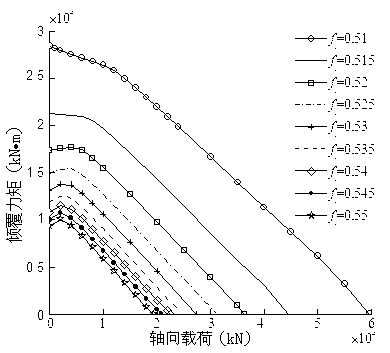

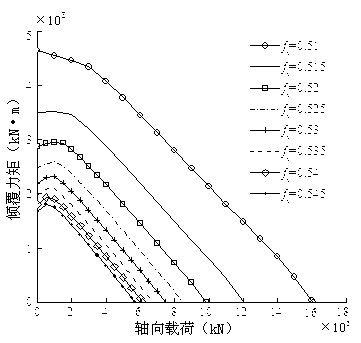

[0067] The method of designing the radius coefficient of curvature of the bearing groove by using the accurate static load curve is as follows:

[0068] Step 1: Calculate the normal contact load and maximum contact load between the steel ball and the inner and outer raceways according to the external load.

[0069] According to the given bearing geometric parameters and inner ring displacement An initial value of , obtained by formulas (1), (2), (4) A , A 0 with , the result is substituted into formula (10) to get ; Then by the formula (9) to fi...

Embodiment 2

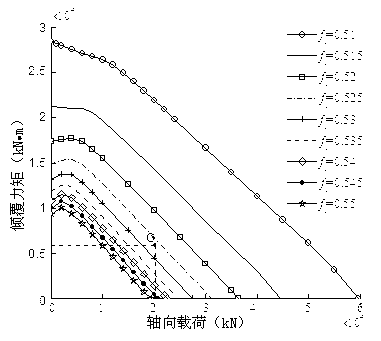

[0076] The design method of the single-row four-point contact ball bearing groove radius coefficient of curvature is similar to that of the double-row four-point contact ball bearing.

[0077] Taking a certain type of single-row four-point contact ball bearing as an example, the structural parameters and material parameters are as follows:

[0078] , , , , . The ultimate working conditions of this type of bearing are: axial force , overturning moment , F r =0kN.

[0079] Step 1: Calculate the normal contact load and maximum contact load between the steel ball and the inner and outer raceways according to the external load.

[0080] Given bearing inner ring displacement An initial value, obtained by formulas (1), (2), (3) A , A 0 with , the result is substituted into formula (10) to get ; Then by the formula (9) to find , obtained by formula (5) ;Bundle with Substitute into formula (7), and let F r =0, yes with Carry out continuous value ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com