Down-the-hole hammer reverse concentric casing drilling tool

A technology of drilling with pipe and reverse circulation, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. It can solve the problems of reduced drilling efficiency, shortened life of drilling tools, and increased drilling costs. Avoid the erosion of the hole wall and the loss of flushing fluid, prevent the cuttings from getting stuck, and avoid repeated crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

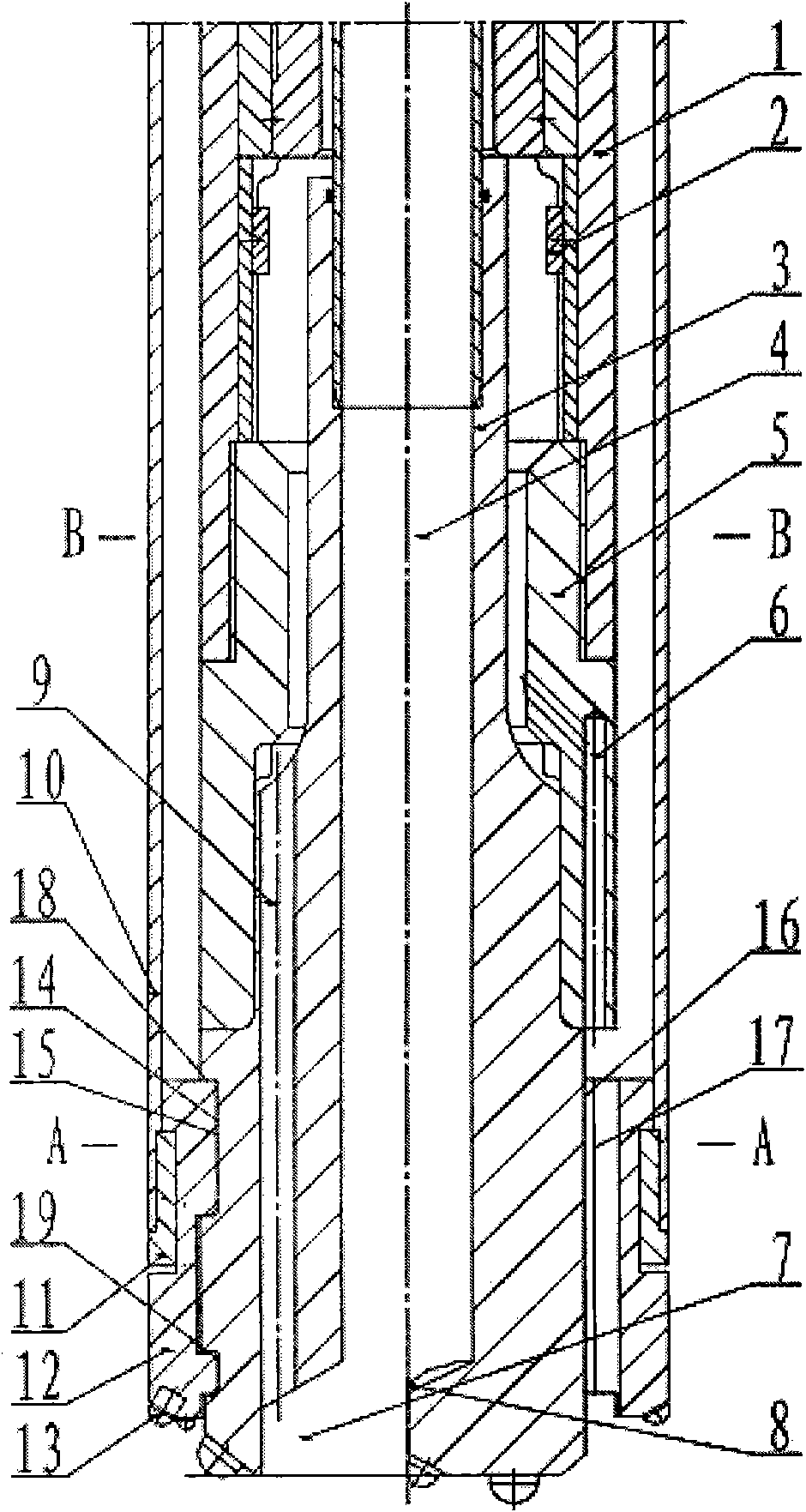

[0021] Below in conjunction with accompanying drawing and embodiment do further detailed description:

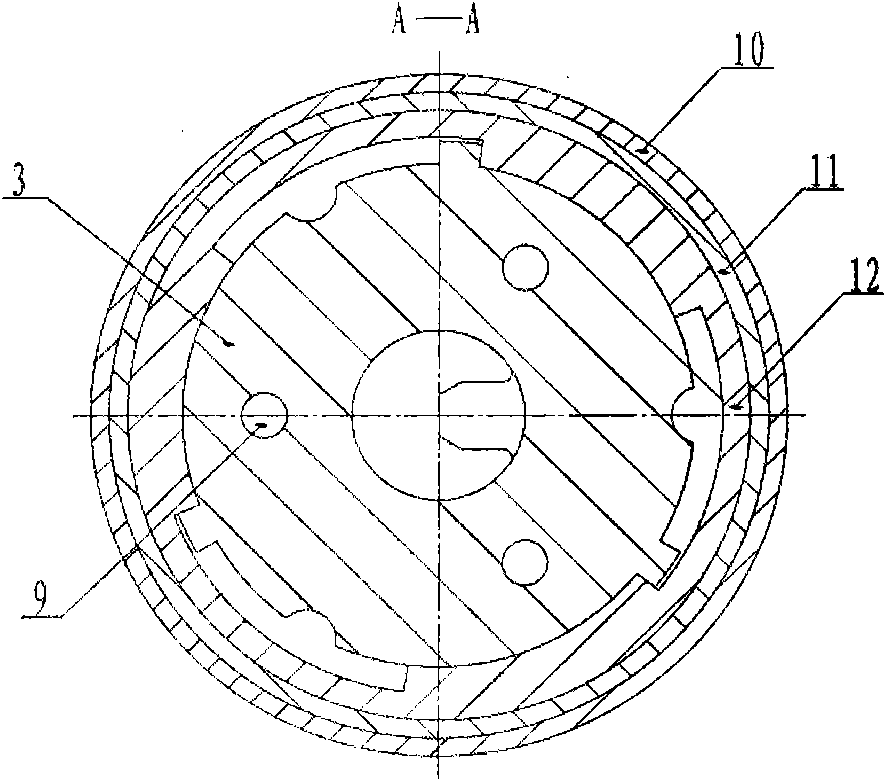

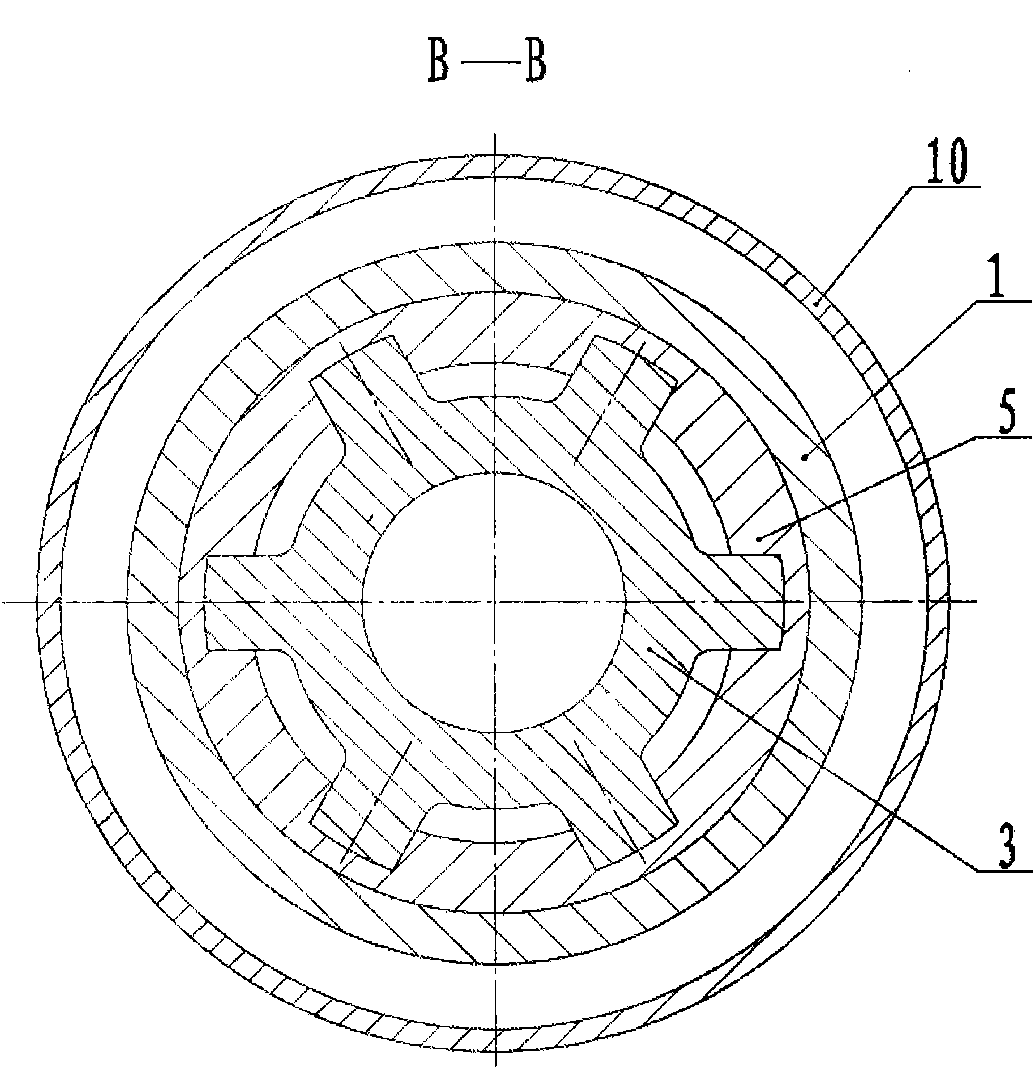

[0022] The DTH hammer reverse circulation concentric heel pipe drilling tool is connected with the guide bit 3 by the hollow DTH hammer 1 through the semicircle clamp 2 and the spline sleeve 5, and the guide bit 3 is provided with an external spline 16 in the axial direction. And cooperate with the inner spline 17 of the annular casing drill bit 12, the guide drill bit 3 is provided with a torsion transmission groove 14, the lower section of the guide drill bit 3 is provided with a bottom spray hole 9, and the lower end of the spline sleeve 5 is provided with an ejector Nozzle 6, diffuser groove 7 is provided at the bottom of central slag discharge channel 4, anti-blocking boss 8 is provided at the bottom of pilot drill bit 3, annular casing drill bit 12 is suspended on the lower end of casing 10 through boot 11, The drill bit alloy 13 is inlaid on the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com