Blast furnace burden distribution intelligent monitoring system and adjusting method

An adjustment method and intelligent monitoring technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as the inability to reflect the influence of air flow fluctuations on the top surface of the furnace, and the inability to simulate changes in the material layer, so as to achieve optimized airflow distribution, convenient maintenance, Use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

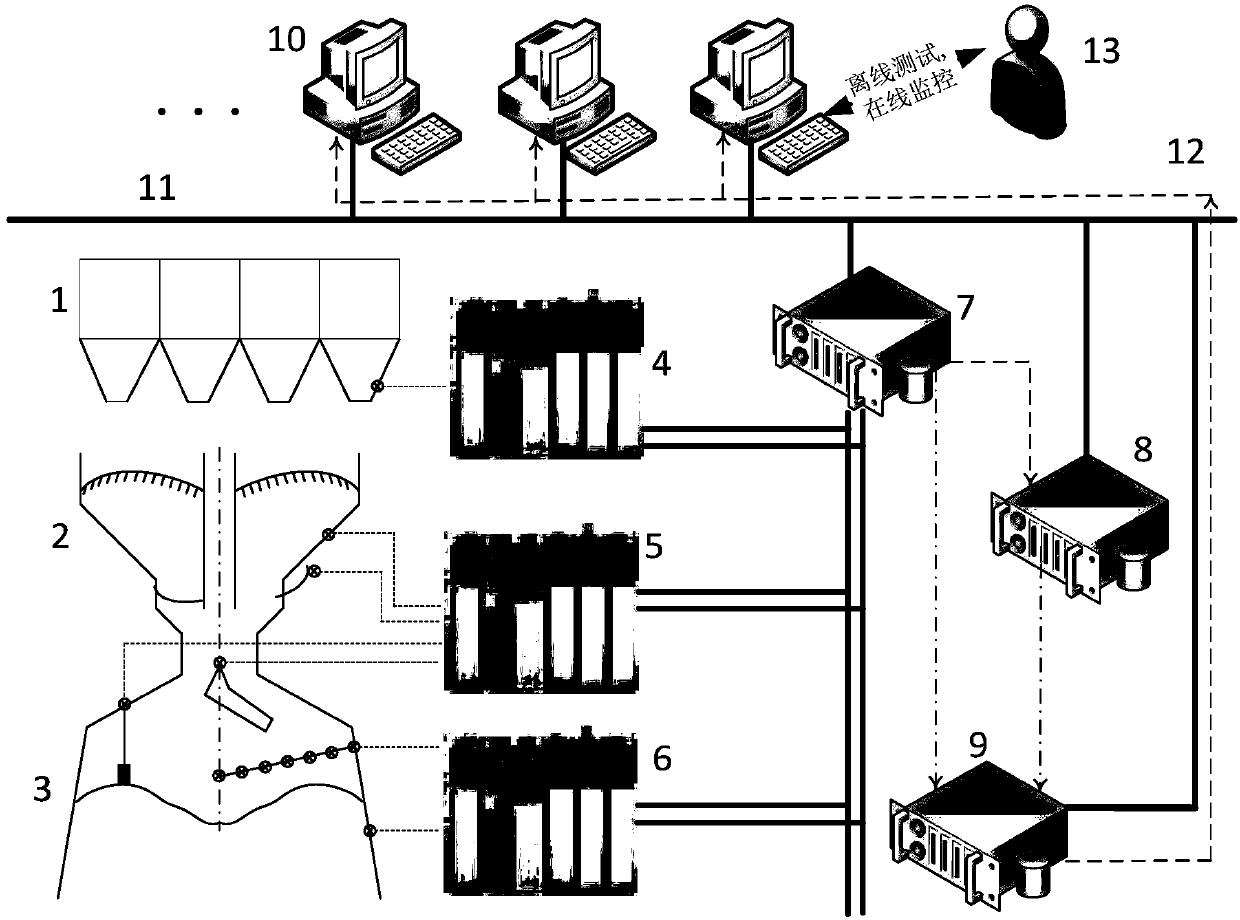

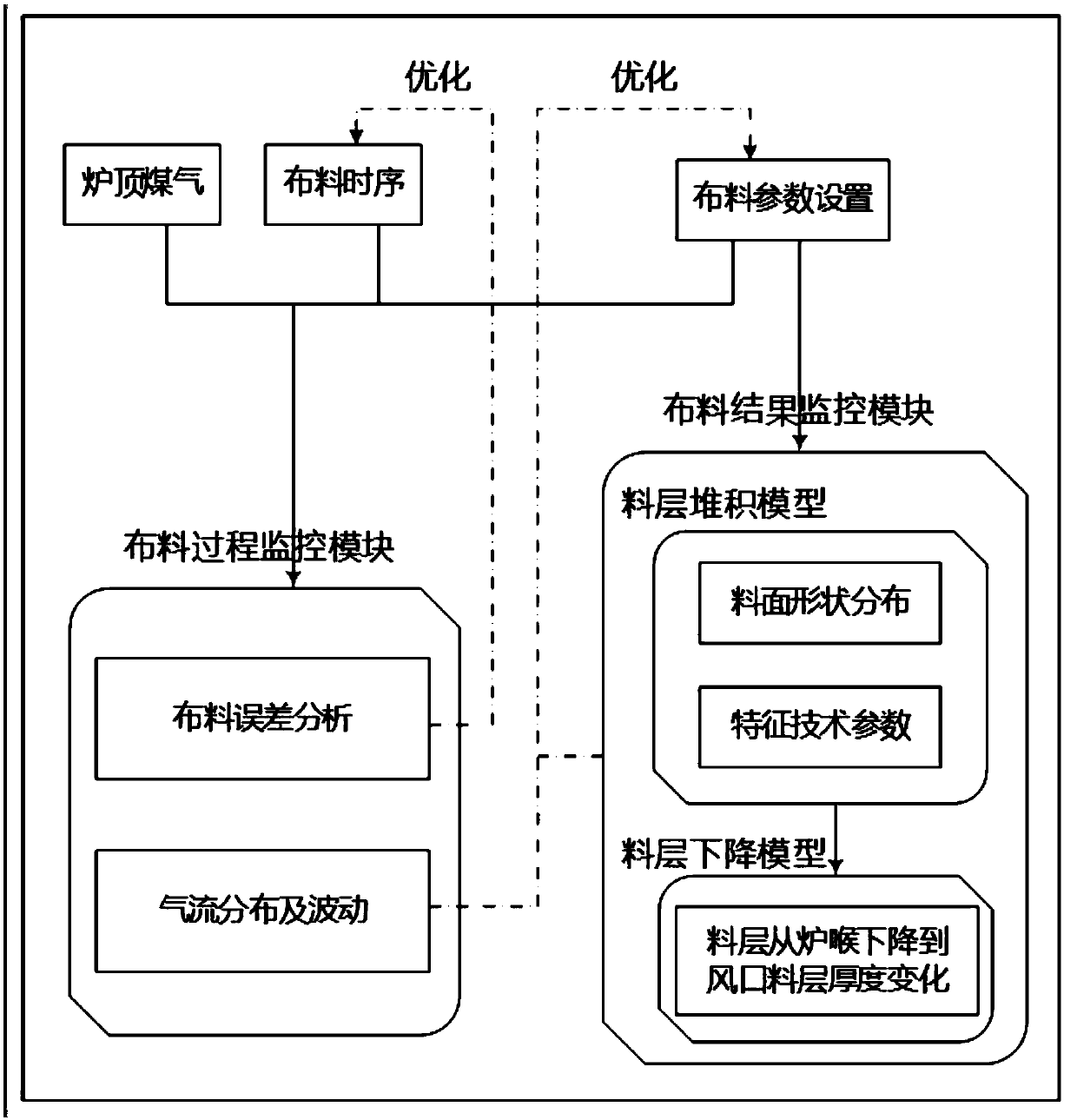

[0023] Such as figure 1 As shown, 1 represents the blast furnace tank system, 2 represents the blast furnace distribution system, 3 represents the blast furnace body system, 4 represents the blast furnace system PC, 5 represents the blast furnace distribution system PLC, 6 represents the blast furnace body system PLC, and 7 represents the communication server , 8 represents the data acquisition server, 9 represents the function server, 10 represents the client, 11 represents the Ethernet, 12 represents the data flow, and 13 represents the blast furnace operator. The communication server collects the setting parameters and real-time data of the blast furnace under-trough system, the furnace top material distribution system and the blast furnace body through the PLC and transmits them to the data acquisition server. The process monitoring mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com