Blast furnace distribution process distribution matrix optimization method and system

A technology of material distribution matrix and charge, which is applied in the field of optimization method and system of material distribution matrix in the process of blast furnace material distribution, can solve the problems such as the inability to realize the adjustment of material distribution matrix, and achieve the effect of improving the utilization rate of raw materials and rationally distributing them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0056] In this embodiment, the method and system of the present invention are implemented for the bell-less blast furnace with tanks in series. The charge goes to the upper tank, the lower tank, the central throat and the rotary chute sequentially through the conveyor belt, and finally the charge is distributed to the inside of the furnace throat. The distribution matrix optimization method of the blast furnace distribution process, such as Figure 8 shown, including:

[0057] Step 1. Set the ideal material surface shape in combination with the feeding information and current furnace conditions;

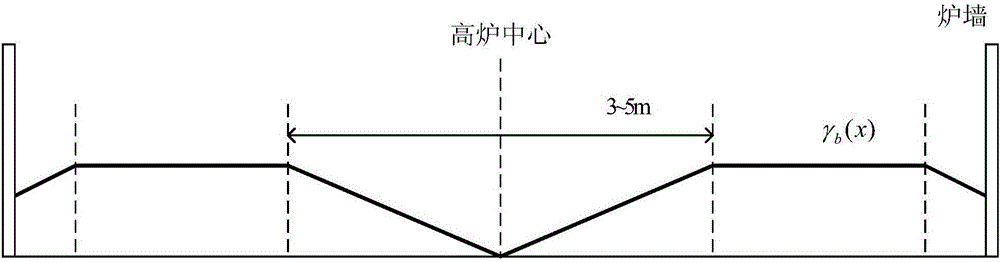

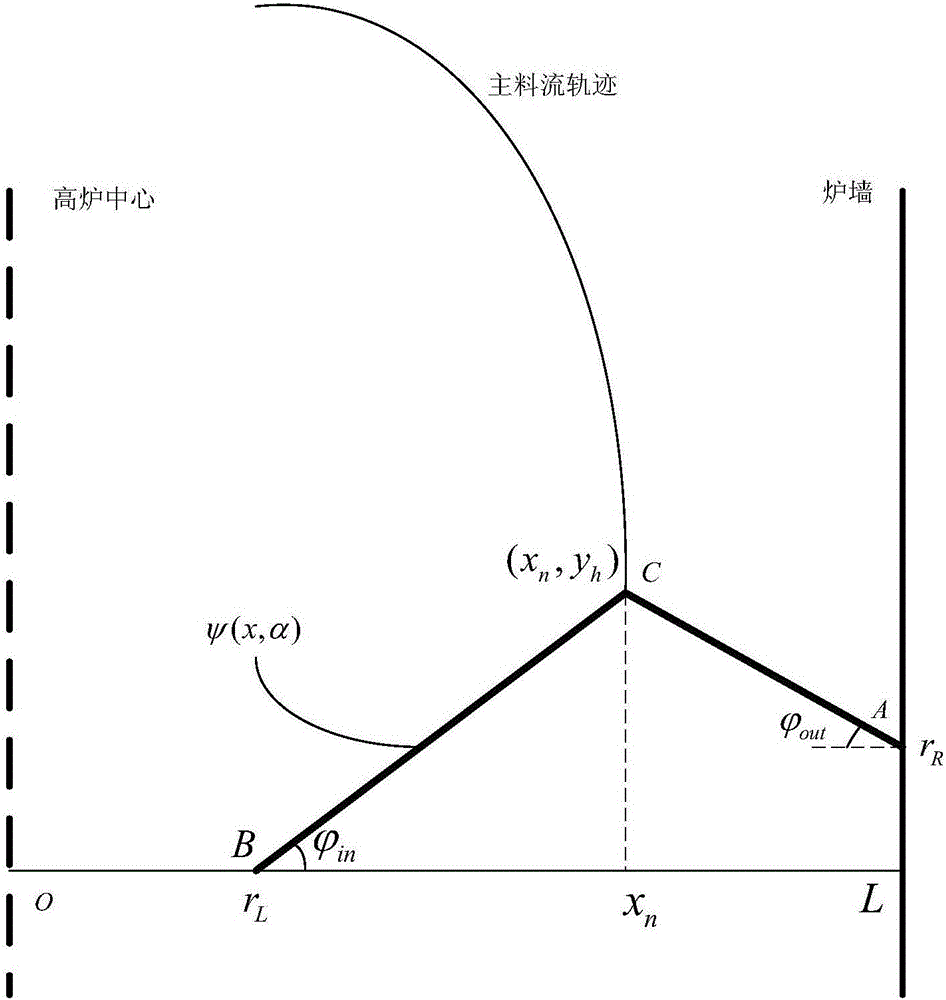

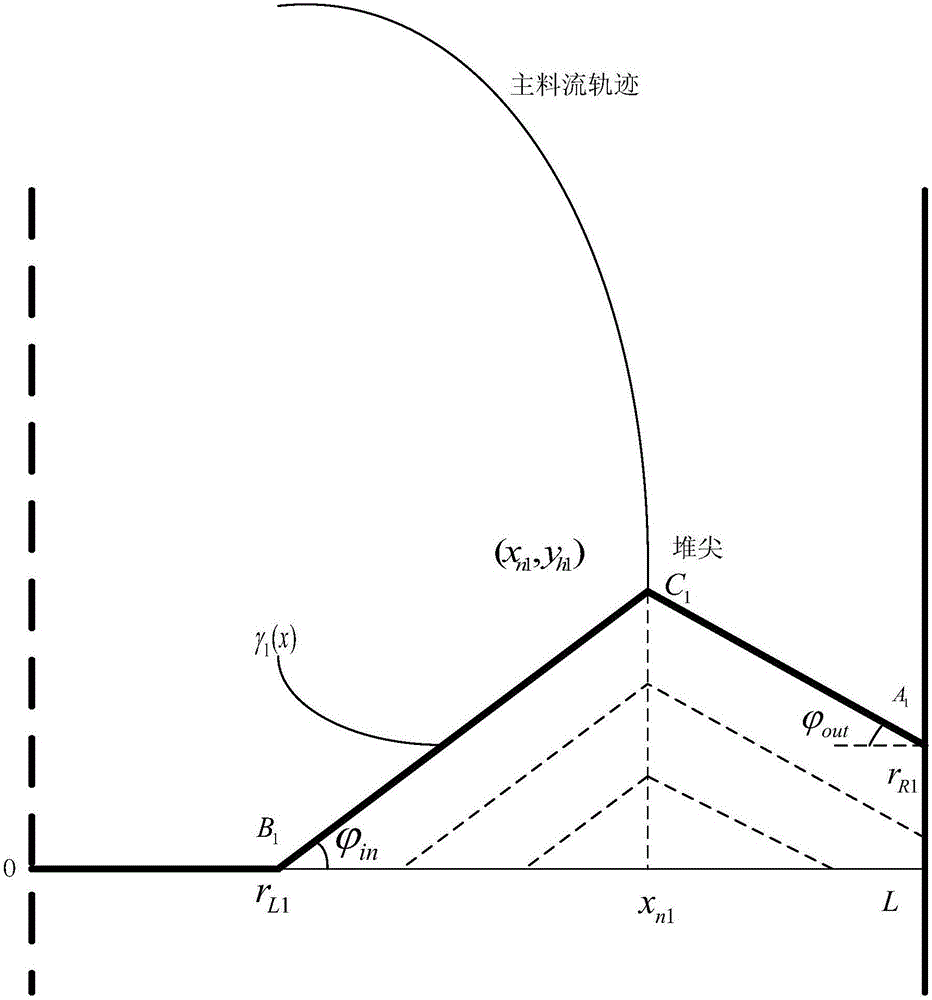

[0058] The material surface shape of the furnace throat position of the bellless blast furnace in series tanks can ensure good gas flow distribution and raw material utilization rate under the ideal material surface. Usually, the ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com