Method and system for estimating charge surface shapes in blast furnace charge distribution process

A technology for material surface and charge, which is applied in the field of material surface shape estimation method and system in blast furnace distribution process, can solve the problems that 6-point radar data cannot accurately estimate the material surface shape, no multi-point radar device is installed, etc., so as to improve the utilization rate of gas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

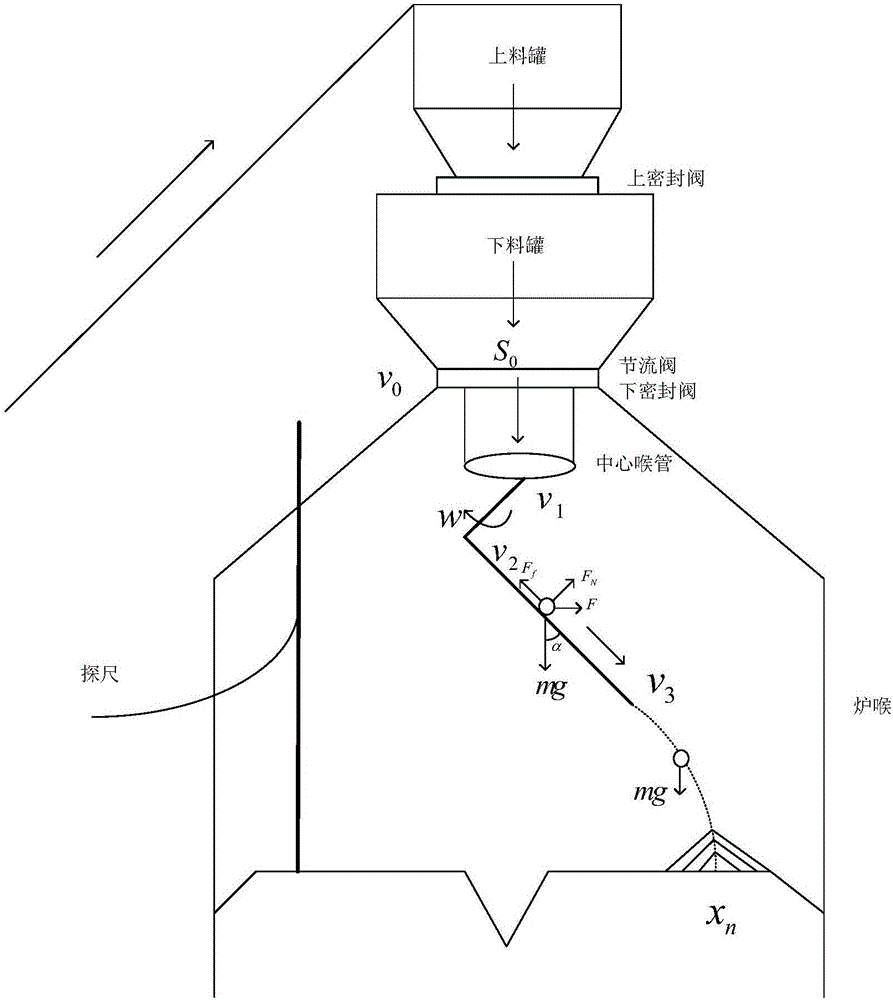

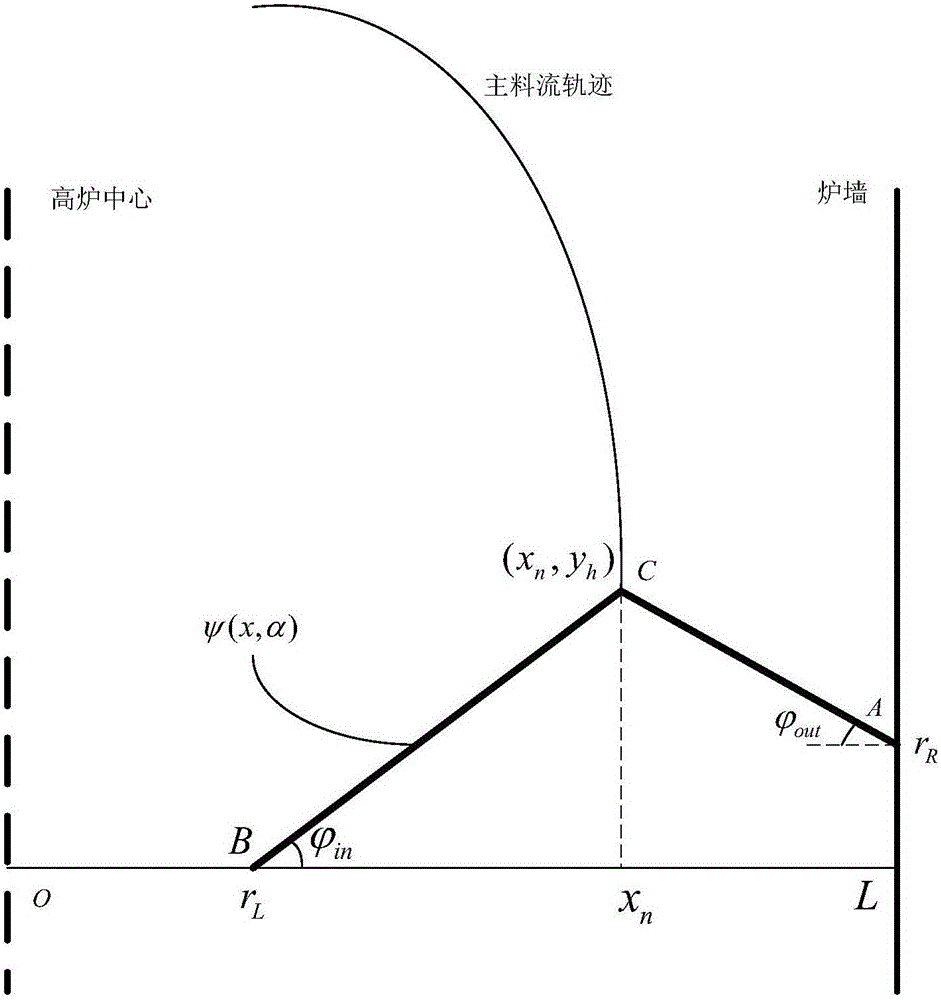

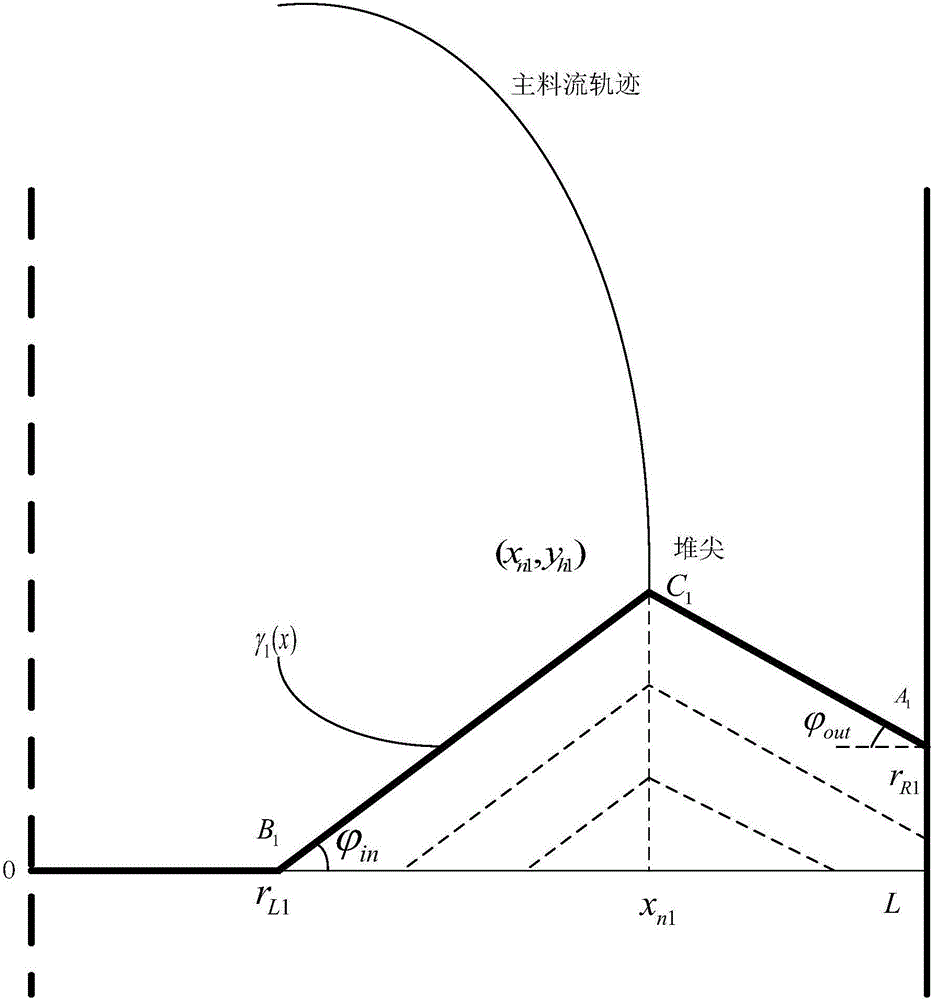

[0057] For such as figure 1 2650m shown 3 In the bell-less blast furnace with string tanks, the charge goes to the upper tank, the lower tank, the central throat and the rotary chute in turn through the conveyor belt, and finally the charge is distributed to the inside of the furnace throat. Consider the charge moving process as particle flow, apply Newton's mechanics to analyze, and find the abscissa of the pile point of the pile. The center of the blast furnace is set as the coordinate origin, and the initial material level is set as the horizontal plane. Calculate the final material surface shape according to the material distribution matrix of the charge.

[0058] In order to ensure the feasibility of the calculation, the following assumptions are made about the state of the charge during the distribution process:

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com