Automatic steelmaking method suitable for low-slag smelting

A technology of less slag smelting and slag dumping, which is applied in the field of metallurgy and steelmaking, can solve the problems of model feedback numerical disorder, end point carbon, temperature failure, large deviation, etc., to improve the end point hit rate, improve labor productivity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings, the present invention will be further described through the embodiments.

[0015] An automatic steelmaking method suitable for slag-less smelting, comprising the following steps:

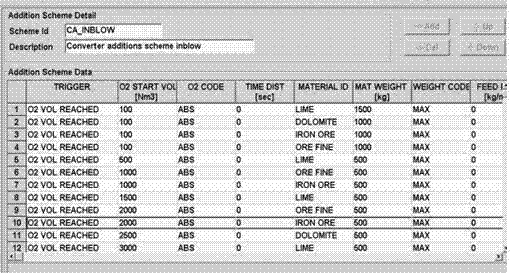

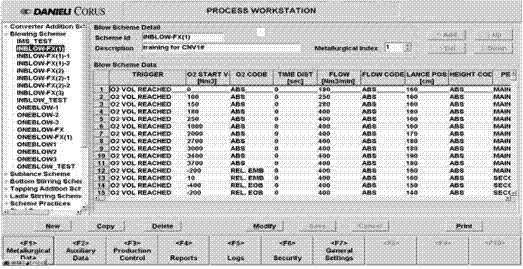

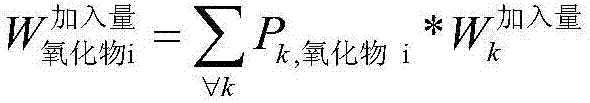

[0016] a. Establish the calculation model of slag dumping and slag retention; the establishment of slag dumping model: on the basis of the original automatic steelmaking model, the calculation of the heat and oxygen balance of the slag in the early stage is added, and the target alkalinity in the early stage is added, which will be based on the on-site smelting data and experiments Chamber simulation, the optimal time interval for pouring slag in the early stage is added to the early stage blowing control of the model, and different blowing times are calculated according to the different components of molten iron; the comparison table between the slag pouring time and the composition of molten iron in this embodiment is shown in Table 1

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com