Multi-information fusion modeling method for shapes of burden surfaces in burden distribution process of blast furnace

A technology of multi-information fusion and modeling method, which is applied in the field of blast furnace material distribution process material surface shape modeling, can solve the problem that it is difficult to obtain completely clear and comprehensive images, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

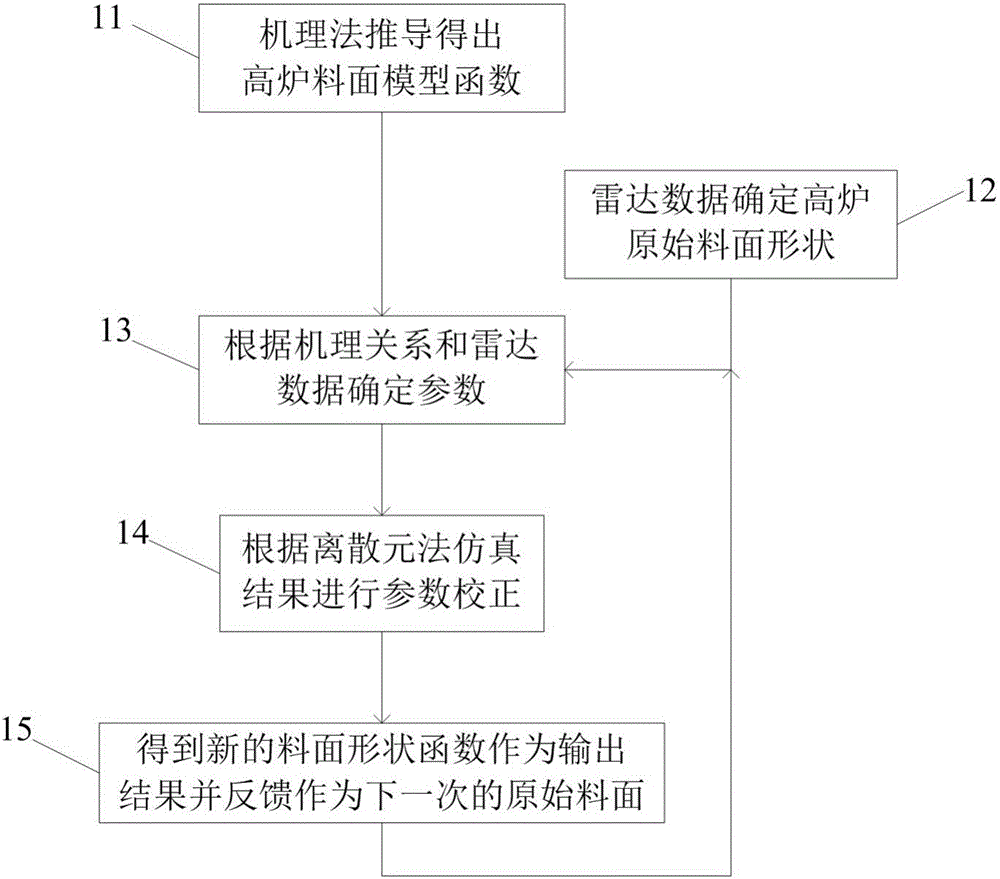

[0024] A method for modeling the shape of the material surface of a blast furnace material distribution process based on multi-information fusion of the present invention, the process diagram of the blast furnace material surface modeling method is as follows figure 1 shown; the method includes the following steps:

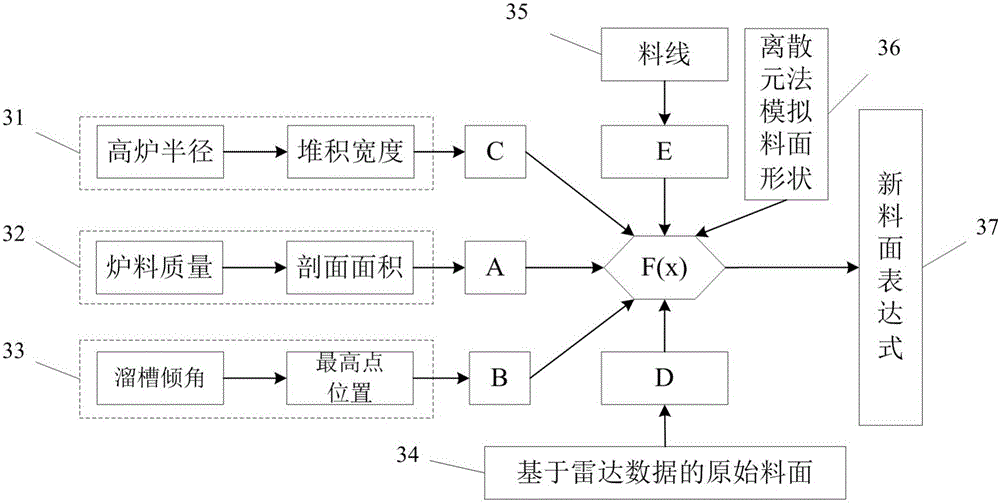

[0025] Step 11: Establishing a charge accumulation model according to fluid mechanics and statistical laws, using a mechanism method to derive a charge level model function in the blast furnace charge distribution process, establishing a parameterized prediction model, solving the shape parameters of the original charge level, and determining the charge accumulation equation;

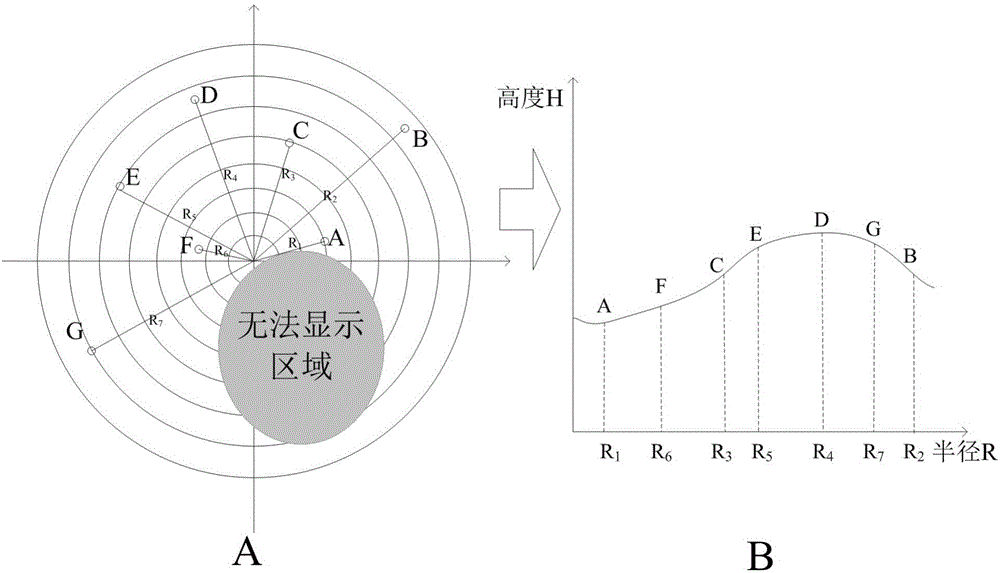

[0026] The described determination of charge accumulation equation is to determine the Gaussian function and trigonometric function as the basic functions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com