Blast furnace hearth sidewall monitoring method

A blast furnace and hearth technology, which is applied in the field of monitoring the side wall of blast furnace hearth, can solve the problems of misjudgment and missed judgment, fluctuation, and no quantitative description of the severity of side wall damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

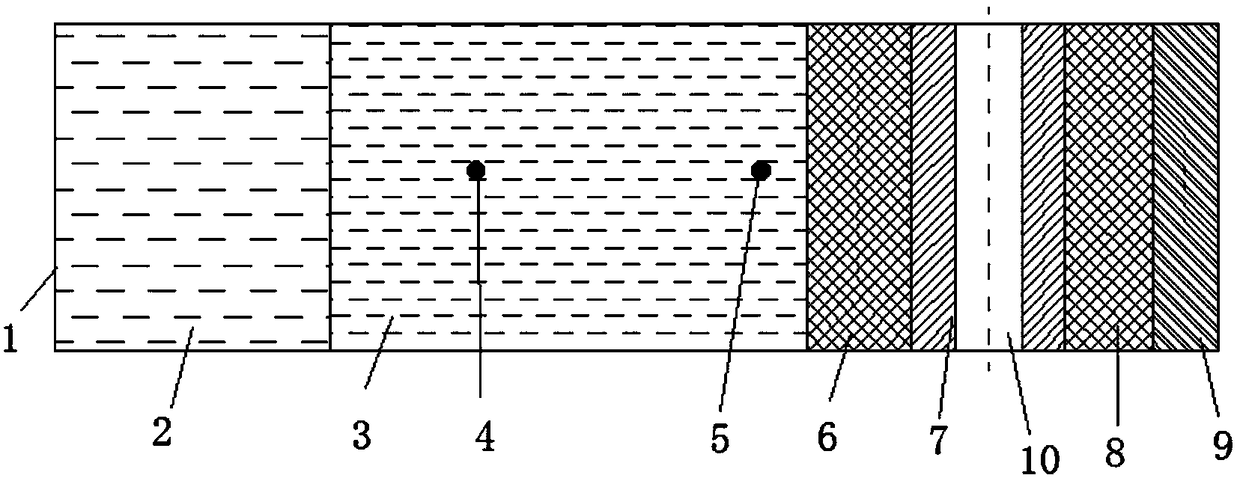

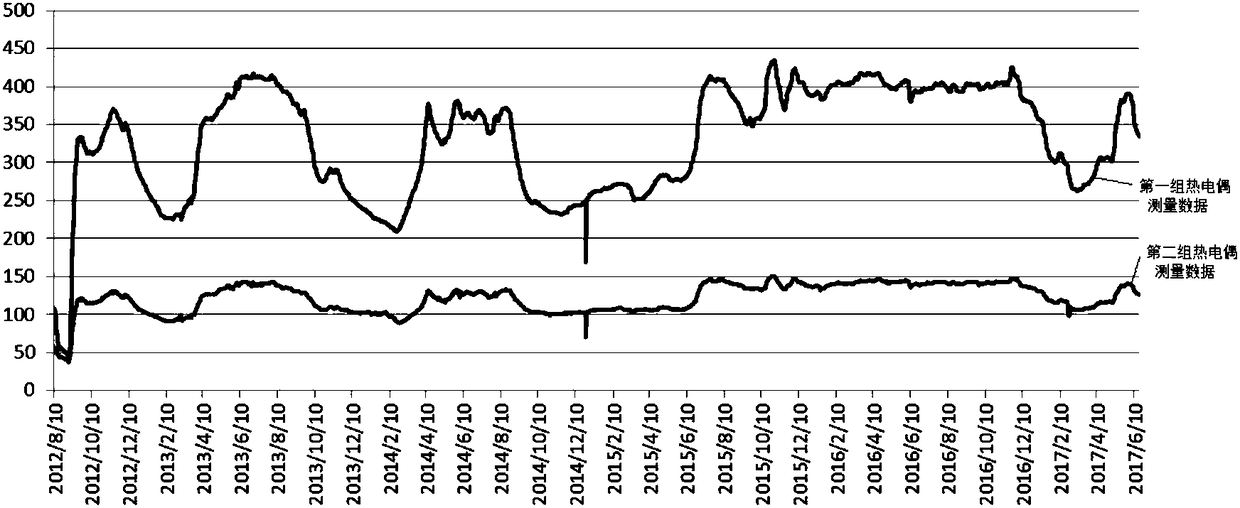

[0092] A method for monitoring the side wall of a blast furnace hearth. The side wall of the blast furnace hearth (that is, from the hot surface of the furnace wall 1 outward) includes a first brick lining 2, a second brick lining 3, and a second brick lining sequentially arranged from inside to outside. A packing layer 6, cooling stave 7, a second packing layer 8 and furnace shell 9, see figure 1 , The second brick lining 3 is provided with a first group of temperature measuring elements 4 and a second group of temperature measuring elements 5 in sequence from the inner side to the outer side of the side wall (here the first group of temperature measuring elements and the second group of temperature measuring elements are used Thermocouple), a cooling water pipe 10 is provided in the cooling wall 7. The monitoring method includes the following steps:

[0093] Obtain the angular heat flux density at the monitoring position of the side wall of the hearth, specifically obtained by...

Embodiment 2

[0166] The difference between Embodiment 2 and Embodiment 1 is:

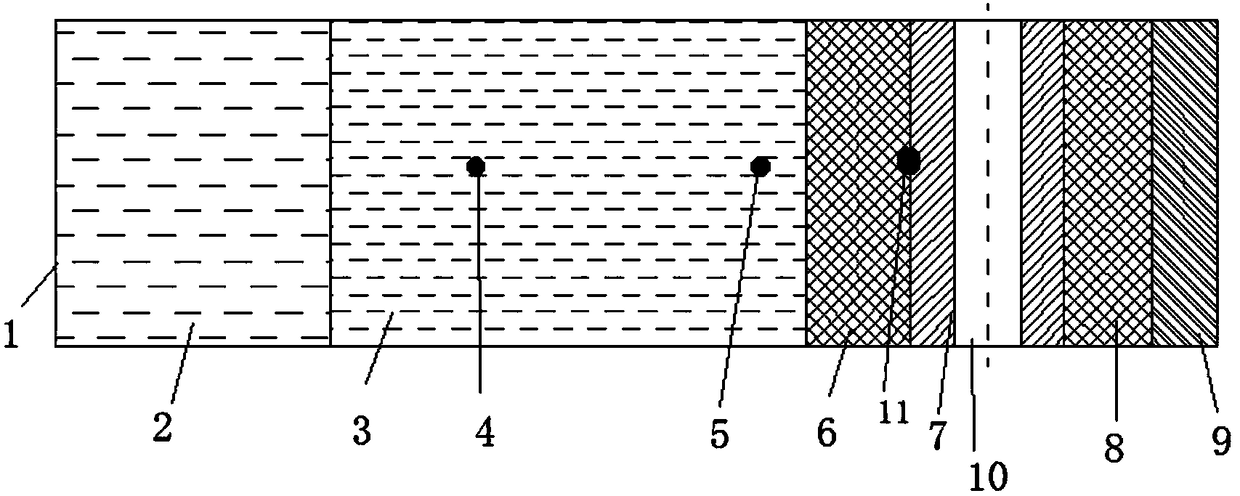

[0167] 1. A measuring element group 11 is installed on the side wall of the blast furnace hearth. The measuring element group includes a heat flow meter for measuring heat density and a third group of temperature measuring elements for measuring temperature. Here, the heat flow meter and the third group are preferred. The temperature measuring elements (optional temperature sensors) are arranged between the first packing layer 6 and the cooling stave 7 (the measuring element group here can be an integrated part of a heat flow meter and the third group of temperature measuring elements), see image 3 . In actual application, the heat flow meter can be installed at any position in the radial direction of the temperature measuring points of the two sets of thermocouples, and the third temperature measuring element is arranged between the first packing layer and the cooling water pipe.

[0168] 2. The angular heat flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com