Robust soft measurement method for quality of blast-furnace hot metal

A high-quality, blast furnace molten iron technology, applied in blast furnaces, blast furnace details, and steel manufacturing processes, etc., can solve the problem of not being able to solve the multicollinear modeling of the output of the hidden layer, unable to suppress the prediction of molten iron quality parameters, and unable to solve the training data. and other problems, to achieve the effect of eliminating multicollinearity problems, accurate and reliable soft measurement, and enhancing model robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Such as figure 2 A robust soft-sensing method for blast furnace molten iron quality is shown, including:

[0036] Step 1. Collect the bosh gas volume u at the current moment 1 (m 3 ), cold air flow rate u 2 (m 3 / min), oxygen-enriched flow u 3 (m 3 / min), air permeability u 4 (m 3 / min.kPa), oxygen enrichment rate u 5 (vol%), theoretical combustion temperature u 6 (℃);

[0037] Step 2, normalize the collected data;

[0038] Step 3. Use the robust soft sensor model of blast furnace molten iron quality constructed by multivariate random weight neural network to perform robust soft sensor of blast furnace molten iron quality to obtain the estimated value of Si content P content estimates Estimated value of S content Hot metal temperature estimate

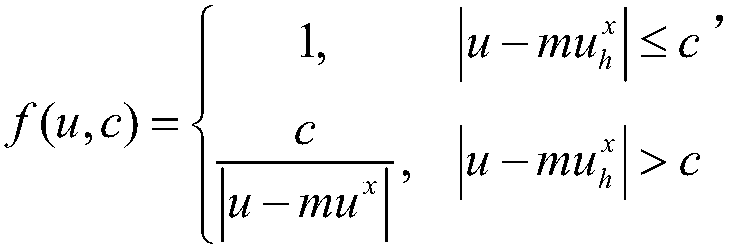

[0039] The blast furnace molten iron quality robust soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com