Integrated power generation and carbon capture using fuel cells

a fuel cell and power generation technology, applied in the direction of hydrogen/synthetic gas production, energy input, energy-based wastewater treatment, etc., can solve the problems of reducing the overall efficiency of the power generation process and the net reduction of the power generation efficiency per unit of fuel consumed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

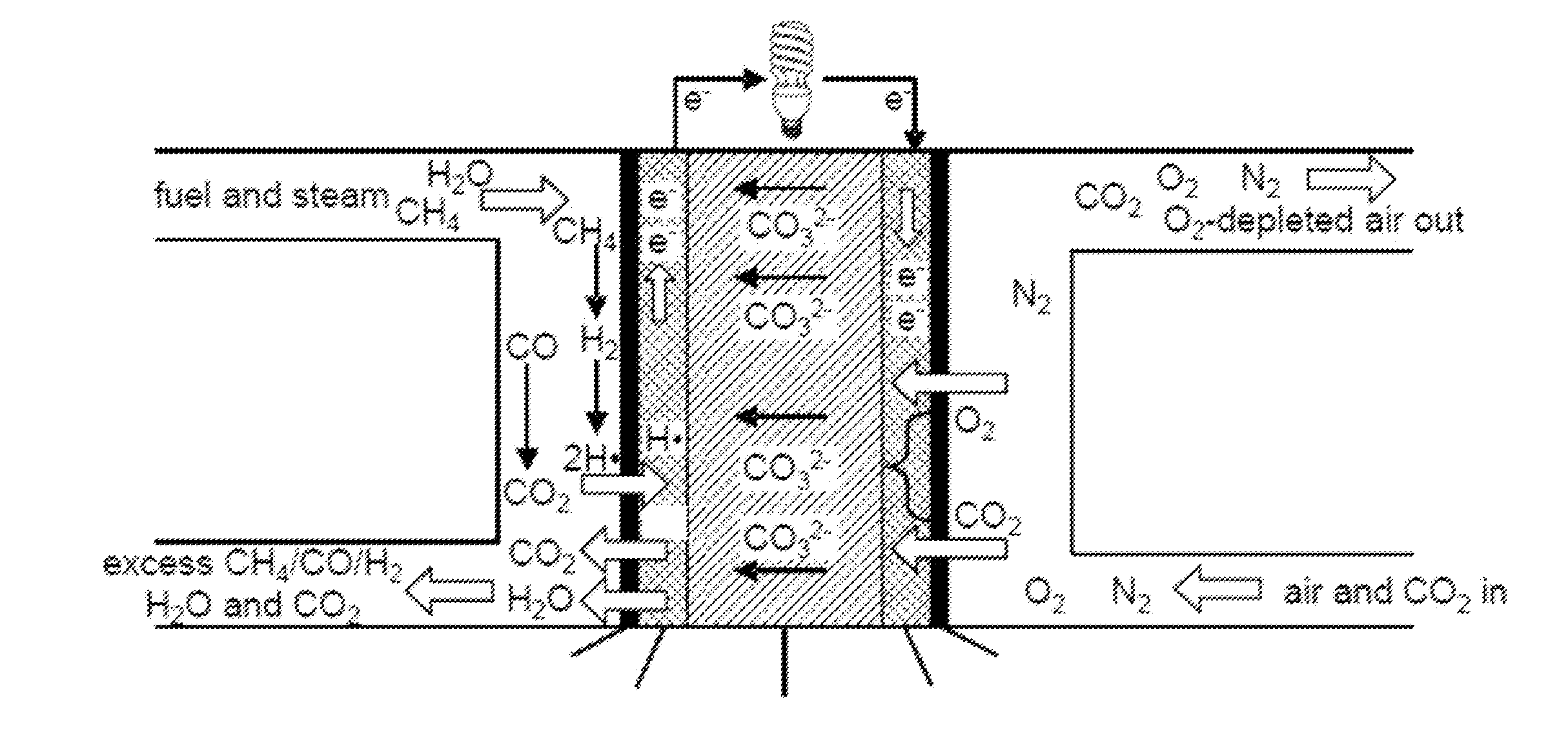

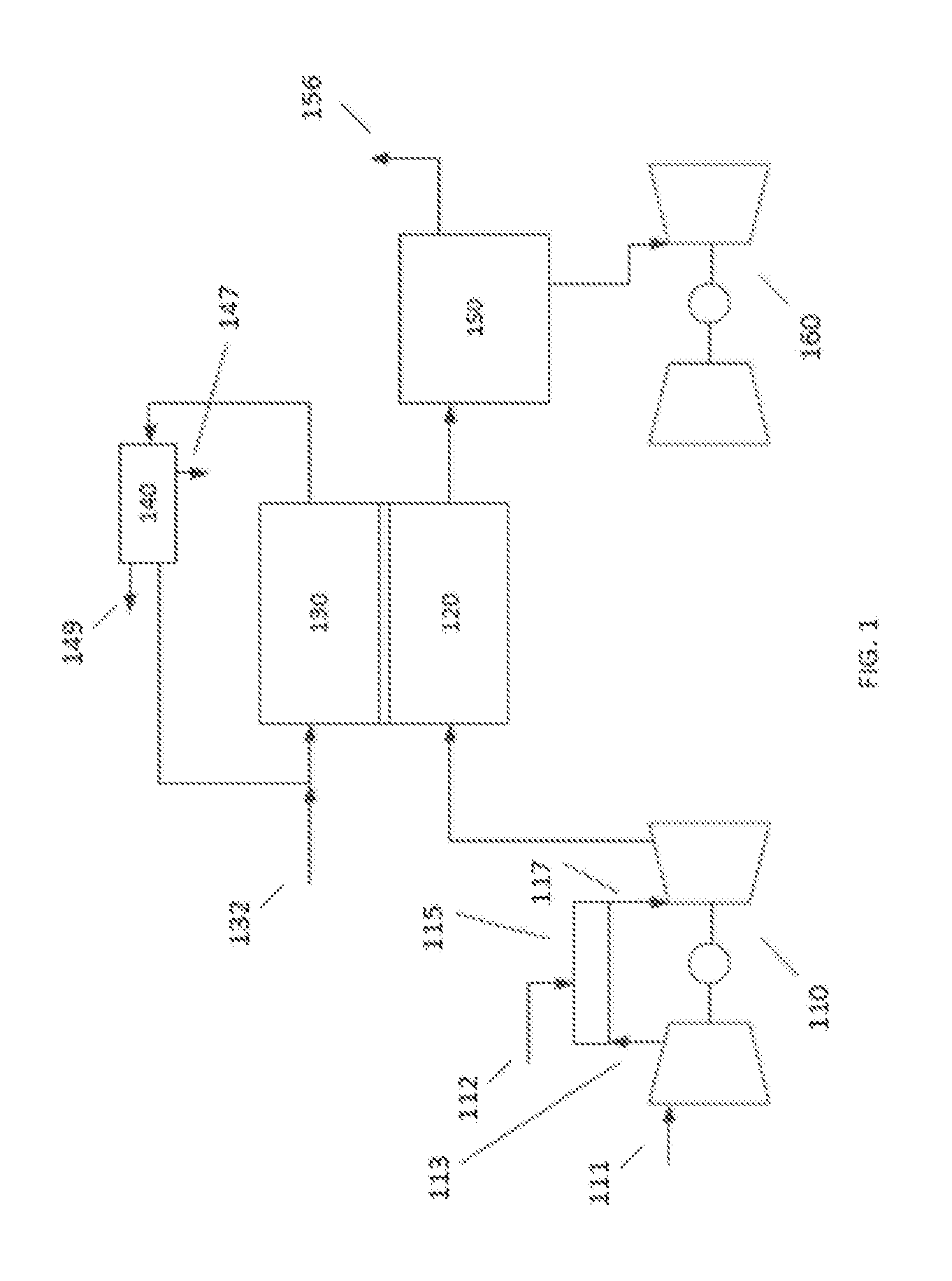

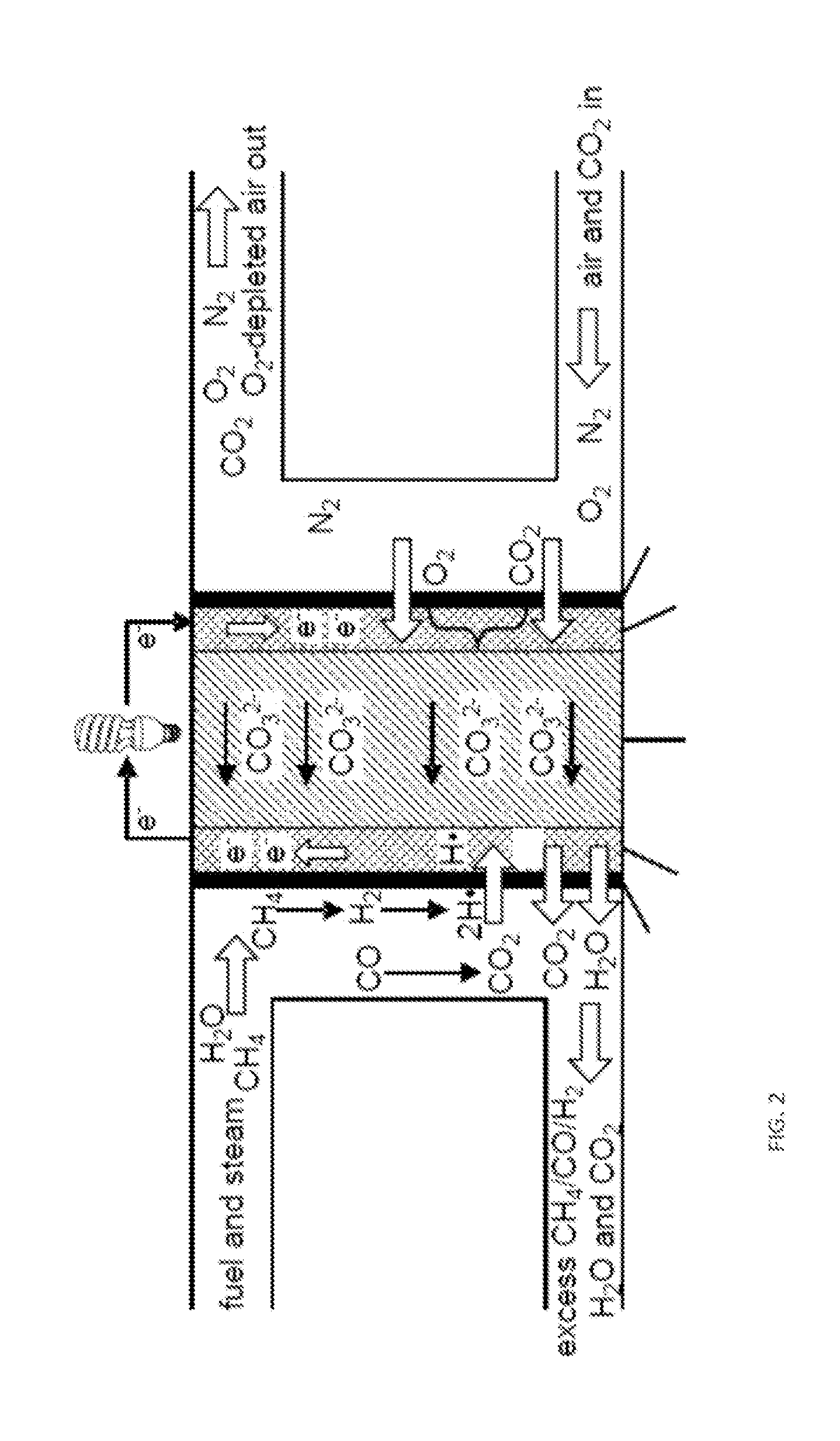

Image

Examples

embodiment 2

[0239]The method of Embodiment 1, wherein a fuel utilization in the one or more fuel cell anodes is about 65% or less (e.g., about 60% or less).

embodiment 3

[0240]The method of Embodiment 2, wherein the fuel utilization in the one or more fuel cell anodes is about 30% to about 50%.

embodiment 4

[0241]The method of claim Embodiment 2, wherein the one or more fuel cell anodes comprise a plurality of anode stages and the one or more fuel cell cathodes comprise a plurality of cathode stages, wherein a low utilization anode stage in the plurality of anode stages has an anode fuel utilization of 65% or less (such as about 60% or less), the low utilization anode stage corresponding to high utilization cathode stage of the plurality of cathode stages, the high utilization cathode stage having a CO2 content at a cathode inlet as high as or higher than a CO2 at a cathode inlet of any other cathode stage of the plurality of cathode stages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com