Vacuum carburizing heat treatment process of 12CrNi3A materials

A vacuum carburizing and carburizing technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low infiltration rate, long carburizing cycle, reduced production efficiency, etc., to improve the infiltration rate , the effect of improving fatigue performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

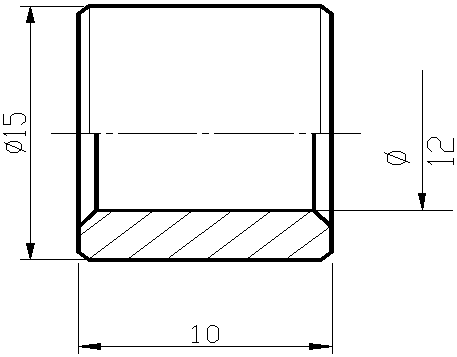

[0027] The present invention is described in detail below in conjunction with the accompanying drawings:

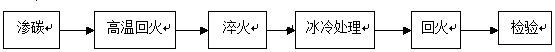

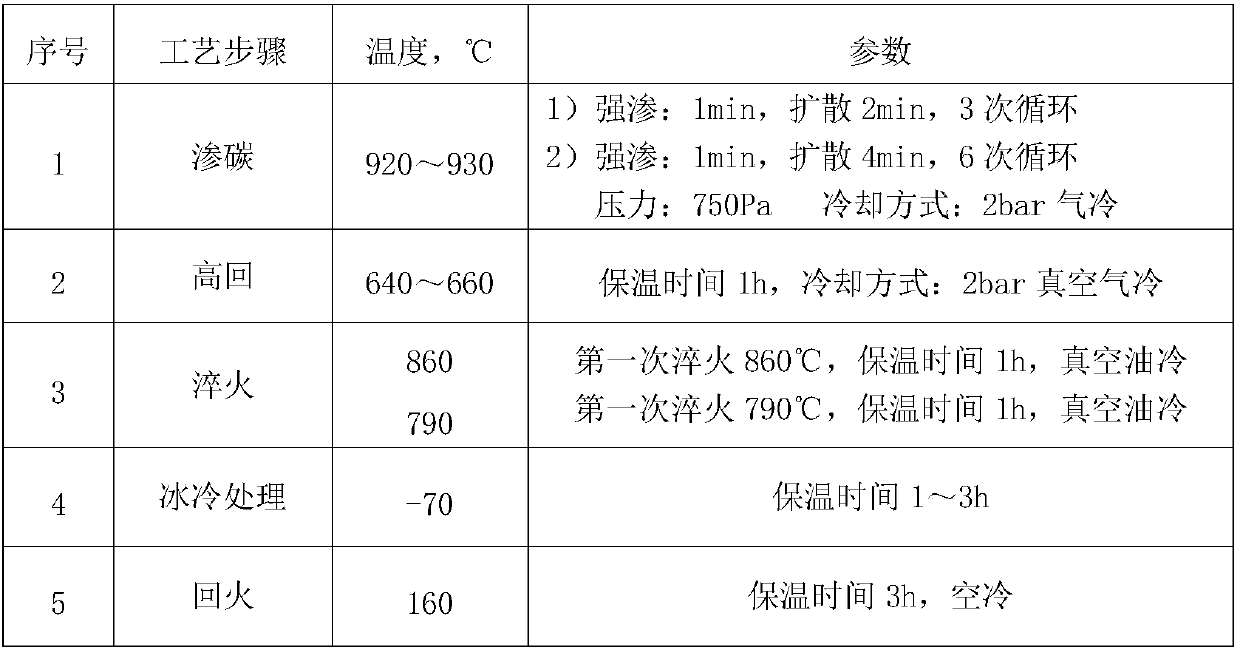

[0028] The process of vacuum carburizing heat treatment of 12CrNi3A material is carried out on the vacuum carburizing equipment, and the heat treatment process steps are (according to figure 2 Process steps for typical parts):

[0029] (1) Carburizing: The carburizing process generally consists of three stages: exhaust heating, carburizing (including strong infiltration and diffusion), and cooling and cooling.

[0030] ① After the parts are installed in the furnace, the gas in the furnace is discharged as soon as possible, and the temperature is raised to 920-930 °C.

[0031] ②After the temperature is stable, the carburizing stage begins, the furnace temperature remains unchanged, and the pressure in the furnace is controlled at 750-800Pa. First perform strong infiltration for about 1min, diffusion for about 2min, and circulate 3 times for a total of about 9min. Then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com