Processing method for high-tenacity metal embedded part in iron casting, embedded part and brake drum

A technology of metal embedded parts and processing methods, applied to brake drums, devices for coating liquid on the surface, coatings, etc., can solve the problems that the strength of brake drums cannot be significantly improved, the toughness is reduced, and the metallographic structure changes. , to achieve the effect of improving comprehensive mechanical properties and service life, improving tensile strength and fatigue strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 The invention relates to a method for treating a high-toughness metal embedded part in an iron casting, which comprises performing anti-carburization treatment on the outer peripheral surface of the high-toughness metal embedded part before casting the iron casting.

[0025] The anti-carburization treatment includes one of electroplating non-ferrous metals and smearing or brushing anti-carburization coatings.

[0026] The treatment method also includes cleaning the high-toughness embedded metal parts before the anti-carburization treatment.

[0027] The cleaning treatment includes one or more of rust removal, oil removal and acid and alkali removal.

Embodiment 2

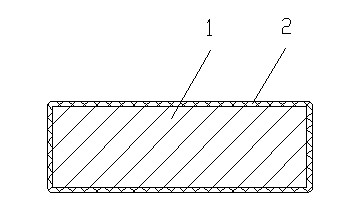

[0028] Example 2 see figure 1 , a high-toughness metal embedded part used in iron castings, comprising a high-toughness metal embedded part body 1, the outer peripheral surface of the high-toughness metal embedded part body 1 is provided with an anti-carburization protective layer 2.

[0029] The anti-carburization protective layer 2 is a coating formed of non-ferrous metals such as copper or nickel.

[0030] The anti-carburization protective layer 2 of this embodiment may also be a coating formed by an anti-carburization paint.

Embodiment 3

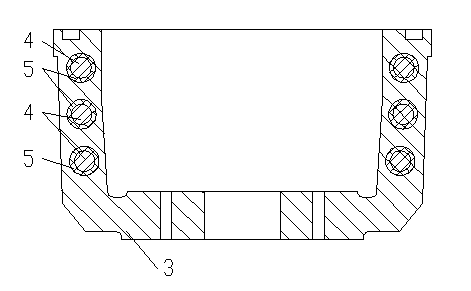

[0031] Example 3 see figure 2 , a brake drum provided with a high-toughness metal embedded part, comprising a brake drum body 3 made of cast iron, the drum wall of the brake drum body 3 is combined with a ring-shaped high-toughness metal embedded part 4 by casting , the outer peripheral surface of the high-toughness metal embedded part 4 is covered with an anti-carburization protective layer 5 .

[0032] The cross-sectional shape of the high-toughness metal embedded part 4 is circular.

[0033] The anti-carburization protection layer 5 is a plating layer formed of non-ferrous metals such as copper or nickel.

[0034] The anti-carburization protective layer 5 of this embodiment may also be a coating formed by an anti-carburization paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com